The accurate analysis of Total Solids in batter and coatings is a key process control measurement in potato processing.

The precise control of solids can enable significant savings, though this is highly dependent upon the availability of real-time results and the accuracy of the analyses.

The DA 7200 empowers production staff to perform their own round-the-clock analysis with instant access to results. These results can be utilized to ensure that proper solids are available to the potatoes, reducing waste and helping to avoid expensive mistakes and potential fines.

Near Infrared Reflectance (NIR) is a technique that is especially suitable for measuring batters and coatings, but historic instrument limitations have impacted users’ capacity to take full advantage of this method.

Complex sample presentation requirements created barriers to accessing NIR. For example, glass sample cells had to be filled properly and were hard to clean, causing analyses to be time-consuming, laborious and error-prone.

Diode Array 7200

The DA 7200 is a full-spectrum NIR instrument that has been specifically developed for use in a wide range of food processing industries. It leverages the power of innovative diode array technology to perform multi-component analysis in 6 seconds, collecting and averaging a significant number full spectra during this process.

The sample is analyzed in an open dish, meaning that historic challenges linked to cell use are avoided, and there is minimal operator impact on results.

Image Credit: PerkinElmer Food Safety and Quality

Experimental

The calibration set was comprised of more than 100 batter and coating samples from several processing plants. These samples included both starch- and flour-based batters and coatings.

Samples were acquired directly at the production line application point, with a portion of each collected sample then placed into a disposable cup prior to spectral data being collected via the DA 7200.

Image Credit: PerkinElmer Food Safety and Quality

A CEM microwave moisture oven was also used to analyze a separate portion of the sample, with results reported in Total Solids. The CEM’s accuracy was measured to be +/- 0.6%. CEM measurements were utilized as reference chemistry results during the calibration process.

Partial Least Squares (PLS) regression was employed in the development of calibrations, with Standard Normal Variant Transform utilized as a data pre-treatment to enhance calibration models.

Results and Discussion

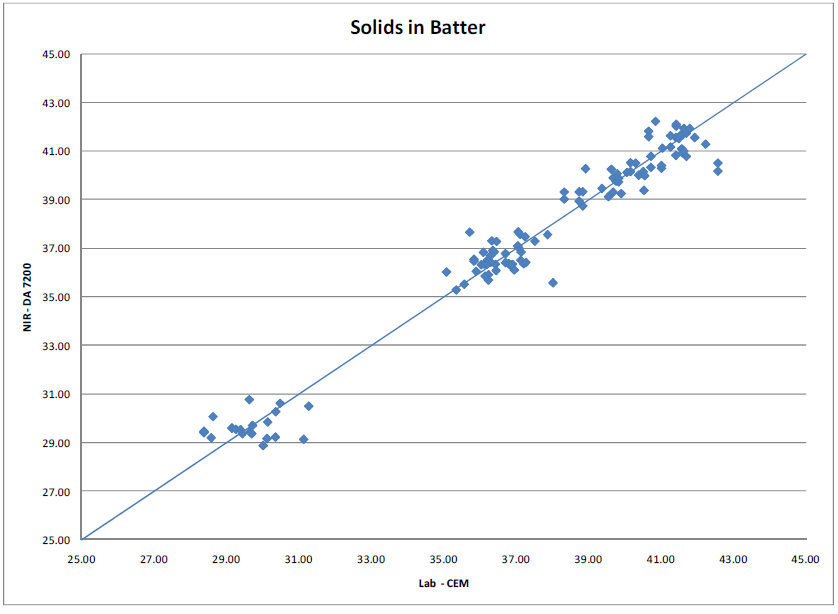

DA 7200 results demonstrated high accuracy when compared against results from reference methods. Statistics for the Total Solids are displayed in the table and graph below.

Source: PerkinElmer Food Safety and Quality

| Parameter |

Range |

Samples |

R |

| Total Solids |

28.39 – 42.57 |

100+ |

0.939 |

Results confirm that Total Solids can be readily and accurately measured across a range of values, with several batters and coatings included in this single calibration.

Differences between the CEM and DA 7200 were found to be of the same magnitude as common differences between two different reference labs, with the DA 7200 proving to be more precise than the reference methods.

This additional precision helps ensure that replicate analyses are representative and repeatable. It may also be possible to analyze additional parameters of a batter or coating simultaneously.

Total analysis time was recorded as 35 seconds per sample for the DA 7200 and 4-7 minutes per sample for the CEM. This included sampling time.

Image Credit: PerkinElmer Food Safety and Quality

This information has been sourced, reviewed and adapted from materials provided by PerkinElmer Food Safety and Quality.

For more information on this source, please visit PerkinElmer Food Safety and Quality.