The doughLAB is a flexible dough rheometer capable of conventional z-arm mixing action. It features variable speed and temperature controls, as well as automated systems designed to control bowl temperature and dispense water into the sample.

Image Credit: PerkinElmer Food Safety and Quality

The doughLAB is highly suited to a range of tasks, including:

- Assessment of processing and bread baking quality

- Assessment of dough characteristics

- Selection of wheat varieties

- Blending of mill streams and wheat varieties

- Testing of a new season’s wheat

- As a quality control measure

The instrument can employ standard or customized test configurations to ascertain the water absorption, development time, dough mixing profile, stability and softening of wheat, durum rye, and composite flours destined for use in baking, milling, and food laboratories.

Description

A number of flour characteristics can be determined to provide an insight into its quality, for example, how much water it must absorb to achieve peak dough consistency, dough stability and mixing time requirements.

The doughLAB provides comparable results to the Brabender Farinograph.

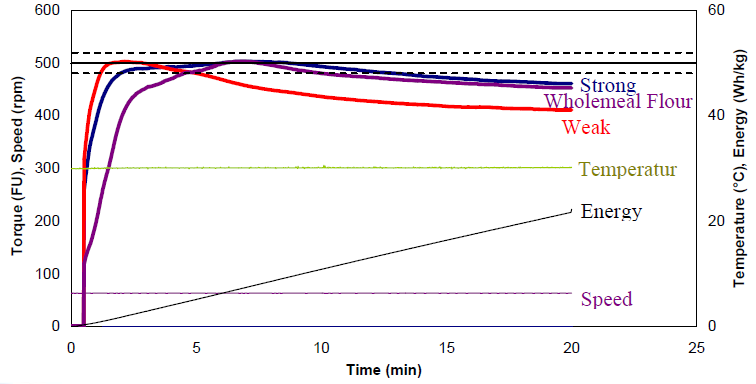

The instrument’s General Flour Testing Method adheres to the Standard Methods of the AACC International (54-21.01), RACI (06-02) and ICC (115/1) methods. These methods require the flour to be mixed at a constant temperature (30 °C) and speed (63 rpm) for a total of 20 minutes.

Torque is employed as a measure of resistance to mixing, and this is presented as a plot against time in the results. The goal of the standard test is to achieve a maximum torque of 500 FU.

Samples may also be assessed to determine a range of parameters, including their stability, softening, optimum water absorption (WA), peak (development) time and mixing tolerance index.

The method can be applied to any flour including, formulations and whole meals.

Figure 1. doughLAB curve of strong, weak and wholemeal flours using the Default method, with a target torque of 500 ± 20 FU. Image Credit: PerkinElmer Food Safety and Quality

Method

A 20-minute mixing profile was used for this study, in line with AACC International Method 54-21.01, RACI Official Method 06-02 and ICC Standard No. 115/1.

Sample Preparation

A total of 300.0 g (or 50.0 g) of sample was prepared at 14% moisture. The user is required to enter the initial water absorption (WA) estimation, and the doughLAB will dispense an appropriate volume of water for the sample size automatically.

Once the test is complete, the doughLAB can calculate the precise WA to reach a peak of 500 FU.

Profile

Source: PerkinElmer Food Safety and Quality

| Time |

Type |

Value |

| 00:00:00 |

Temp |

30 °C |

| 00:00:00 |

Speed |

63 rpm |

| 00:20:00 |

End |

|

Premixing time: 60 s

Premixing speed: 63 rpm |

Measure

Measurements were conducted as follows:

- PT: Peak torque (FU)

- Stab: Stability (min)

- WA: Water absorption (%)

- ST: Softening (FU)

- DDT: Dough development time (min)

- MTI: Mixing tolerance index (FU)

The method can be employed in quality control measures, or in the comparison of samples, for example, weak versus strong, hard versus soft, different varieties or mill streams.

It is also suitable for the assessment amylase activity in flour in in the investigation of formulation effects, for example, the impact of added lipids, emulsifiers, sugars or salts.

Target torque often varies from country to country. As an example, target torque in the UK is defined as 600 FU (5882 mNm for the 300.0 g bowl, 1176 mNm for the 50.0 g bowl).

This information has been sourced, reviewed and adapted from materials provided by PerkinElmer Food Safety and Quality.

For more information on this source, please visit PerkinElmer Food Safety and Quality.