Ensuring compliance with pre-determined temperatures is a process and quality-defining factor throughout almost all industrial production stages. Contactless measuring infrared thermometers are widely known for temperature measurements. This is also the case for the measurement of metals.

Image Credit: tdhster/shutterstock.com

Suitable monitoring and control of process temperatures require exceptional guidance by the producer or a basic understanding of the measurement techniques required on the part of the customer.

Crucial parameters, including emissivity and reflection, and those for measuring mistakes, will be detailed in the following article. The effect on the measurement of metals will also be presented, and it will demonstrate why a reliable and reproducible measurement is possible.

Alongside time, temperature is another frequently measured physical property. Infrared temperature measurement devices determine temperatures without contacting the object through the infrared radiation the object emits.

The questions that arise are, how do non-contact temperature measurements work, and what are the challenges of measuring metallic surfaces?

The Infrared Radiation Array

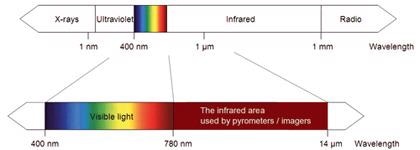

The surface of each object/body, with a temperature above the absolute zero of 0 K (-273.15 °C), emits electromagnetic radiation proportional to its internal temperature. The infrared radiation array only covers a small part of the total electromagnetic radiation array.

It begins at the visible range of about 0.78 μm and ends at wavelengths around 1000 μm.

Wavelengths ranging from 0.7 to 14 μm are critical for infrared temperature measurement. Anything over these wavelengths means that the energy level is so low that the sensitivity of the detectors is not adequate to detect them - as shown in the illustration below.

Image Credit: Optris GmbH

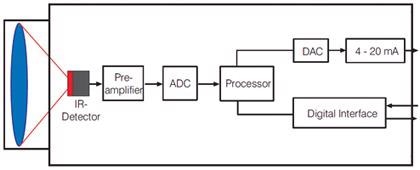

The radiation of the object/body permeates into the atmosphere and can be focused on a detector element with the assistance of a lens. The detector element produces an electrical signal corresponding to the radiation.

This amplified signal uses successive digital signal processing to transfer it into an output signal proportional to the object's temperature. The measuring value can be released as a signal or shown on a display.

Standardized outputs to pass on measurement results for system control are available in form of linear 0/4-20 mA, 0-10 V, and as a thermocouple signal.

Additionally, most infrared thermometers in current use offer digital interfaces (USB, RS232, RS485) for advanced digital signal processing and access to the device parameters.

Image Credit: Optris GmbH

The behavior of infrared radiation on metal surfaces is described in the following section. Firstly, the detector and the conversion of the signal into an object temperature will be presented.

Temperature Calculation via Infrared Radiation

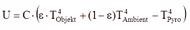

The detector as a radiation pick-up determines the most crucial element of each infrared thermometer. A signal is produced through emergent electromagnetic radiation, which can then be evaluated. The detector signal U is related to the object temperature TObject as follows:

The resulting detector signal from the object's emitted radiation within the total radiation array increases in relation to the fourth power of the absolute temperature of the object. This means that if the temperature of the measuring object increases twofold, the detector signal will then increase by a factor of 16.

The formula changes in conjunction with the emissivity ε of the object and the reflecting ambient radiation of the object surface TAmbient – the self-radiation of the infrared thermometer TPyro must also be taken into account:

Moreover, infrared thermometers are non-functioning within the entire radiation array. The exponent is reliant on the wavelength. N stands for the wavelength from 1 to 14 μm in the range of 17…2, for shortwave measuring devices that define the temperature of metal (1.0 to 2.3 μm), the range is between 15 – 17:

The object temperature presented is due to a shift of the previously mentioned formula. The results of these calculations are stored as an array of curves withing the EEPROM of the infrared thermometer for all temperatures that occur:

Therefore, infrared thermometers receive an appropriate amount of signal for the temperature measurement.

From the formula, it is possible to see that the wavelength range (radiation array), the reflecting ambient radiation as well as the emissivity are critical for precise temperature measurement.

The significance of these parameters will be explained hereafter.

The Black Body as an Importance Reference

Around 1900, Planck, Stefan, Boltzmann, Wien and Kirchhoff identified and presented the electromagnetic spectrum in more detail, establishing qualitative and quantitative coherences for the description of infrared energy.

The black body is the foundation for an understanding of the physical basics of non-contact temperature measurement technology and for the infrared thermometer calibration.

On the one hand, the black body is a body that absorbs all radiation that occurs. Neither reflection (ρ = 0) nor transmission (τ = 0) show up on the body. On the other hand, and depending on its own temperature, the black body emits the maximum possible energy for each wavelength.

Constructing a black body is simple. A thermal hollow body has a small opening at one end. If the body is heated and achieves a certain temperature, a balanced temperature spreads inside the hollow body.

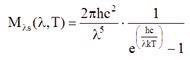

The radiation law by Planck demonstrates the fundamental correlation for non-contact temperature measurements. It outlines the spectral specific radiation Mλs of the black body into the half-space which is contingent on its temperature T and the wavelength λ (c: light speed, h: Plank constant):

For each temperature example, the diagram shows the logarithmic spectral emission Mλs of a black body across the wavelength.

Image Credit: Optris GmbH

Numerous coherences can be observed, but only two will be established hereafter. It is possible to acquire the emitted radiation value of the body as a whole by integrating the spectral radiation intensity for all wavelengths from 0 to infinite.

This correlation is known as the Stefan-Boltzmann-Law. The practical significance for non-contact temperature measurement has been previously detailed in the paragraph regarding temperature calculation.

The second coherence, which is clear from the graphic outline, is that the wavelength which is comprised of the maximum of radiation, runs into the shortwave area as temperatures increase. This behavior underpins the displacement law of Wien and can also be obtained using Plank's equation through differentiation.

Therefore, the high radiation is a reason – but not the most important one – as to why metal surfaces can be measured with short wavelengths at high temperatures.

The long wave range also consists of high intensity. Reflection and emissivity and their influence on measurement errors have a much greater impact as metals are selective emitters.

Metal Surfaces as Selective Emitters

Realistically, there are only a few bodies that meet the black body ideal. In practice, radiation surfaces are utilized for sensor calibration, which reaches emissivities up to 0.99 within the wavelength area desired.

The object temperature can be determined through the radiation measurement of the emissivity ε (Epsilon), which declares the relationship between the real radiation value of the object and that of the black body for the equivalent temperature.

Thus, the emissivity is always between zero and one; the radiation part missing is compensated through the emissivity indication.

Many of the surfaces measured are made up of a constant emissivity throughout all wavelengths, but in contrast to the black body, they emit less radiation.

Thus, they are known as 'grey body'. A number of non-metallic solids demonstrate a high and relatively constant emissivity across the long-wave spectral range independent of their surface condition.

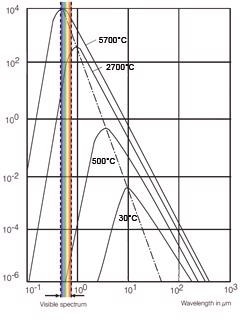

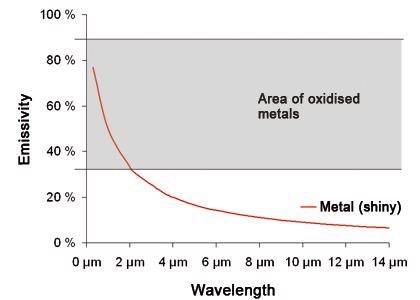

Objects, known as selective emitters, are metal surfaces whose emissivity, among other things, is dependent on the temperature and the wavelength. There are numerous critical factors why the measurement of metals should only be conducted within the shortwave range.

Firstly, metal surfaces at high temperatures as well as short wavelengths (2.3 μm; 1.6 μm; 1.0 μm) are not only comprised of the highest radiation but also of the highest emissivity.

Secondly, they adapt to the emissivity of metal-oxides so that temperature differences, provoked by fluctuating emissivity (heat tint), are minimized.

Image Credit: Optris GmbH

Another key factor for the consideration of a short wave infrared thermometer is that metals, in contrast to other materials, can contain unknown emissivities. Short wave devices substantially reduce the measurement errors at erroneously adjusted emissivities.

Image Credit: Optris GmbH

Reproducible Measurements Despite Reflection

The lower the surface emissivity, the more the infrared thermometer receives reflected radiation from the surrounding environment. As most of the bodies, like metals, do not contain a transmission within the infrared range, the following formula can be applied:

ε + p = 1

In this instance, ε is the emissivity and ρ the reflection.

The infrared radiation, which is determined by the device and translated into temperature, is not only impacted by the metal surface's emissivity (and the compensated radiation share) but also through any hot objects present in the surroundings (TAmbient) such as ovens and other components.

The parameter TAmbient must be taken into account the lower the temperature of the metal surface that is to be measured and the higher the reflected temperature in the immediate surroundings.

The amount of reflection is usually de facto directed and, as such, is easy to resolve. The amount of reflection can be determined by size and secures reproducible measurement results.

Infrared Thermometers in Practice: Inductive Hardening and Inducement Processes

An example for the measurement of metal surfaces is heat treatment over induction hardening. Throughout this process, a component is positioned in a robust alternating field and then heated and frozen into the desired structure.

It is possible to modify the local penetration of the heat into the material via frequency control; only certain parts of the component receive treatment.

The desired structure of the metal depends on an optimal temperature-time process. Therefore, it is essential to permanently monitor the temperature.

Important parameters of infrared thermometers are:

- Fast temperature control through measurements within 1 ms

- Measurement of small components through high optical resolutions (measurement sizes starting from 0.7 mm) and spot size marking through double laser sighting

- Reliable temperature measurement of metals from 50 °C up to 1800 °C

- The sensing head is detached from the electronic box, therefore, there is no influence of the electromagnetic field on the measurement results

- Surrounding temperature compensation (TAmbient), e.g. through reference temperature

- Wavelength (1.0 μm / 1.6 μm / 2.3 μm) particularly for metal surfaces

Image Credit: Optris GmbH

Optris Infrared Thermometers for Temperature Measurements of Metal

Optris supplies an extensive range of metal pyrometers as well as infrared cameras for several applications across the metal industry.

Image Credit: Optris GmbH

High Temperature Measurement on Metal

The following infrared thermometers are well-suited for measuring of extremely high temperatures on metals, metal oxides as well as ceramics:

- Pyrometer optris CT 1M / 2M: 250 °C ... 2.200 °C*

- Pyrometer optris CTlaser 1M / 2M with innovative double laser: 250 °C ... 2.200 °C*

- Hand thermometer optris P20 1M / 2M: 385 °C ... 1.800 °C*

- Ratio pyrometer optris CTratio 1M: 700 °C ... 1.800 °C

Low Temperature Measurement on Metal

A great number of applications in the metal industry occur in lower temperature ranges. For such instances, Optris can provide the following infrared thermometers:

- Pyrometer optris CT 3M: 50 °C ... 1.800 °C

- Pyrometer optris CTlaser 3M with innovative double laser: 50 °C ... 1.800 °C*

Measurement of Molten Metals

Thanks to exceptionally short measuring wavelengths, the following pyrometers are an ideal match for measuring the temperature of molten metals:

- Pyrometer optris CTlaser 05M: 1.000 °C ... 2.000 °C

- Hand thermometer optris P20 05M: 1.000 °C ... 2.000 °C

Thermal Cameras for Measurements on Metal

The thermal imagers of the optris PI series also provide special devices for temperature measurements on metal, which cover the following temperature ranges:

- Infrarotkamera optris PI 1M: 450 °C ... 1800 °C*

- Infrarotkamera optris PI 05M: 900 °C ... 2000 °C*

This information has been sourced, reviewed and adapted from materials provided by Optris GmbH.

For more information on this source, please visit Optris GmbH.