In this interview, Robert Bellinger, Product Applications Manager from Evident talks to AZoM about the Smart Experiment Manager software that was designed as an add-on feature to guide users through the process of imaging samples via test routines.

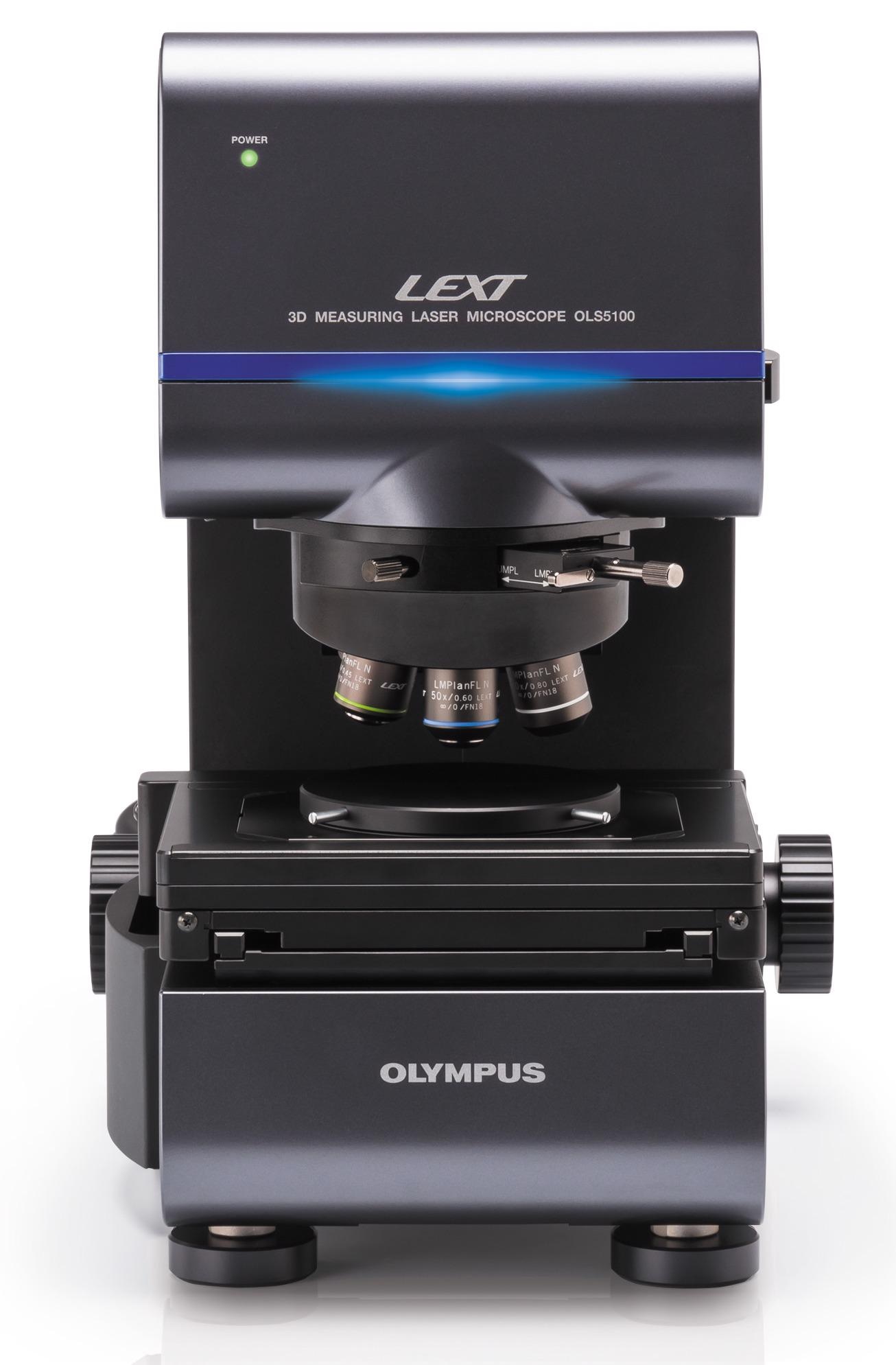

Can you describe the specific tasks that the LEXT™ OLS5100 3D Laser Scanning Microscope was built for?

The LEXT™ OLS5100 is a surface metrology system designed to offer very high resolution, high magnification surface imaging in three dimensions.

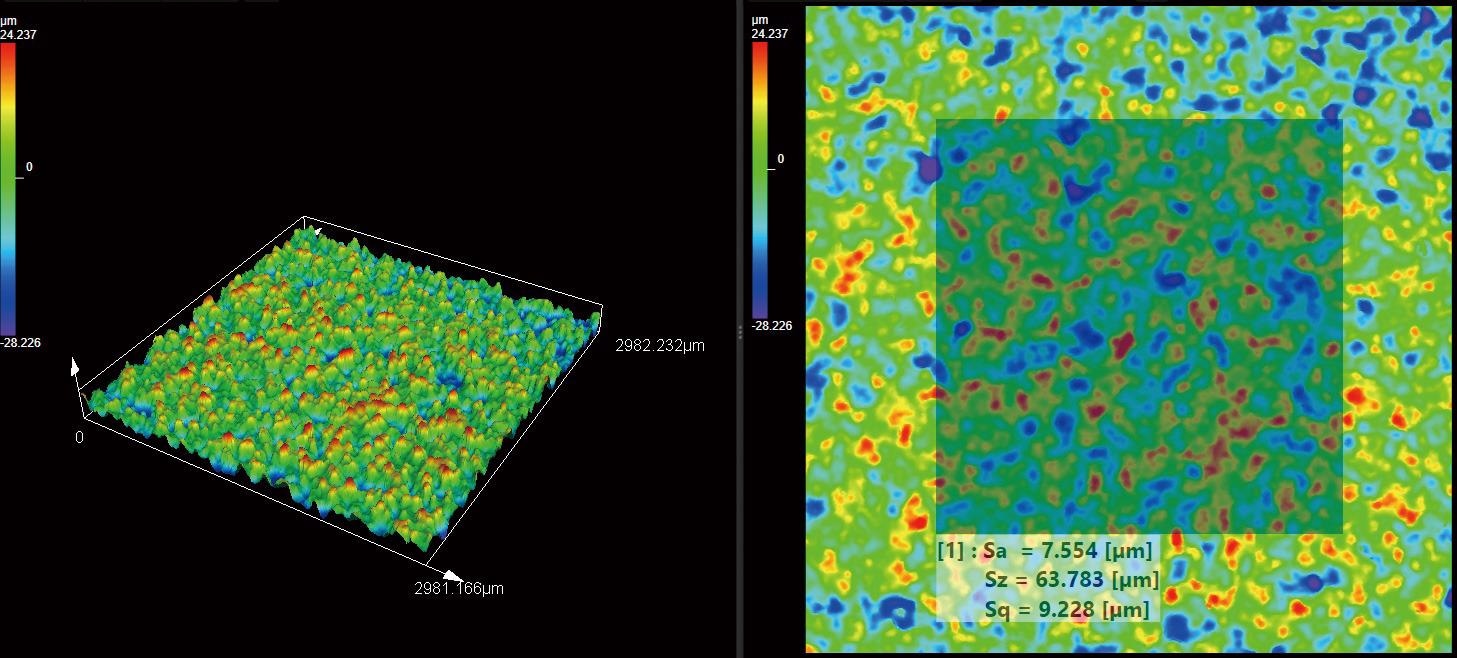

When we investigate surface metrology, we are typically interested in the morphological features on the surface of samples at higher magnifications. For example, surface roughness analysis may be used to determine the finish of a material based on its roughness values.

Correlative testing may be performed on materials after they have been through a specific coating or finishing process. The finish may be measured at different intervals, including pre-coating, post-coating and after post-environmental testing.

Surface metrology can also be used to image for or quantify surface defects, even when working with materials at the nanometer height scale.

The OLS5100 microscope is highly flexible. It can acquire color images, providing quantitative data on the surface and rendering it in high resolution. It can also be used for real color applications to determine if a feature exhibits different color bands or color intensities at different positions on the surface.

The instrument’s software can be used to measure a wide range of features, including heights, widths, surface roughness, angles and tilts on surfaces.

Image Credit: Evident

Can you tell our readers more about the Smart Experiment Manager?

The Smart Experiment Manager is a software add-on feature that guides users through the process of imaging samples via test routines.

It simplifies the workflow, enabling users to perform experiments quicker and more precisely, even if the experiment transitions between different operators.

For example, users developing a new case design for tablets will need to evaluate these test cases based on a number of different test factors. A new case may feature specialized coatings designed to make it more durable, so users may be looking to test the durability of these coatings.

This testing will likely evaluate the surface finish using a surface roughness experiment. It will begin by measuring a brand new, freshly coated surface before using a wear testing machine to evaluate this further. The goal is to identify how and to what extent surface wear occurs.

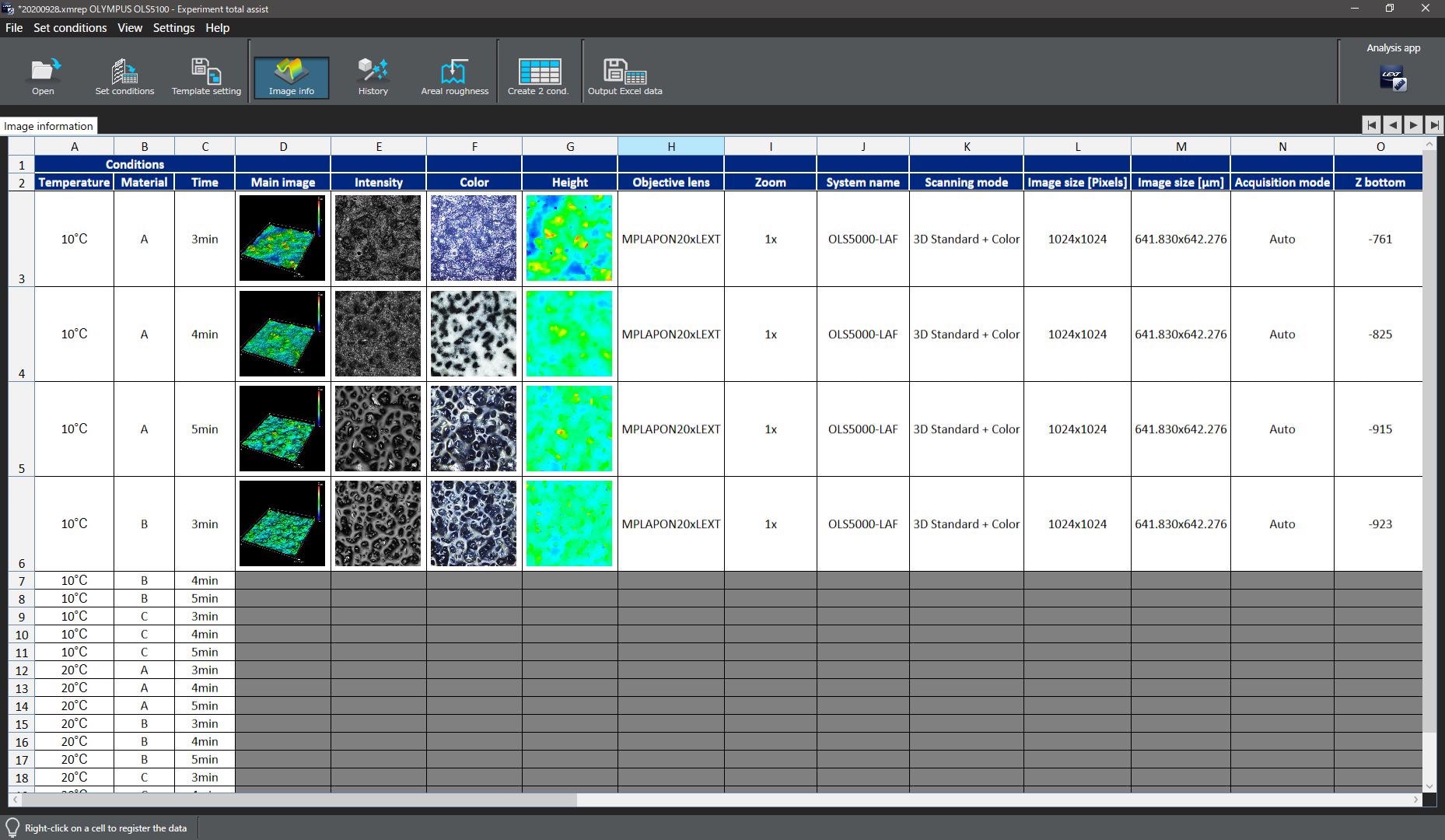

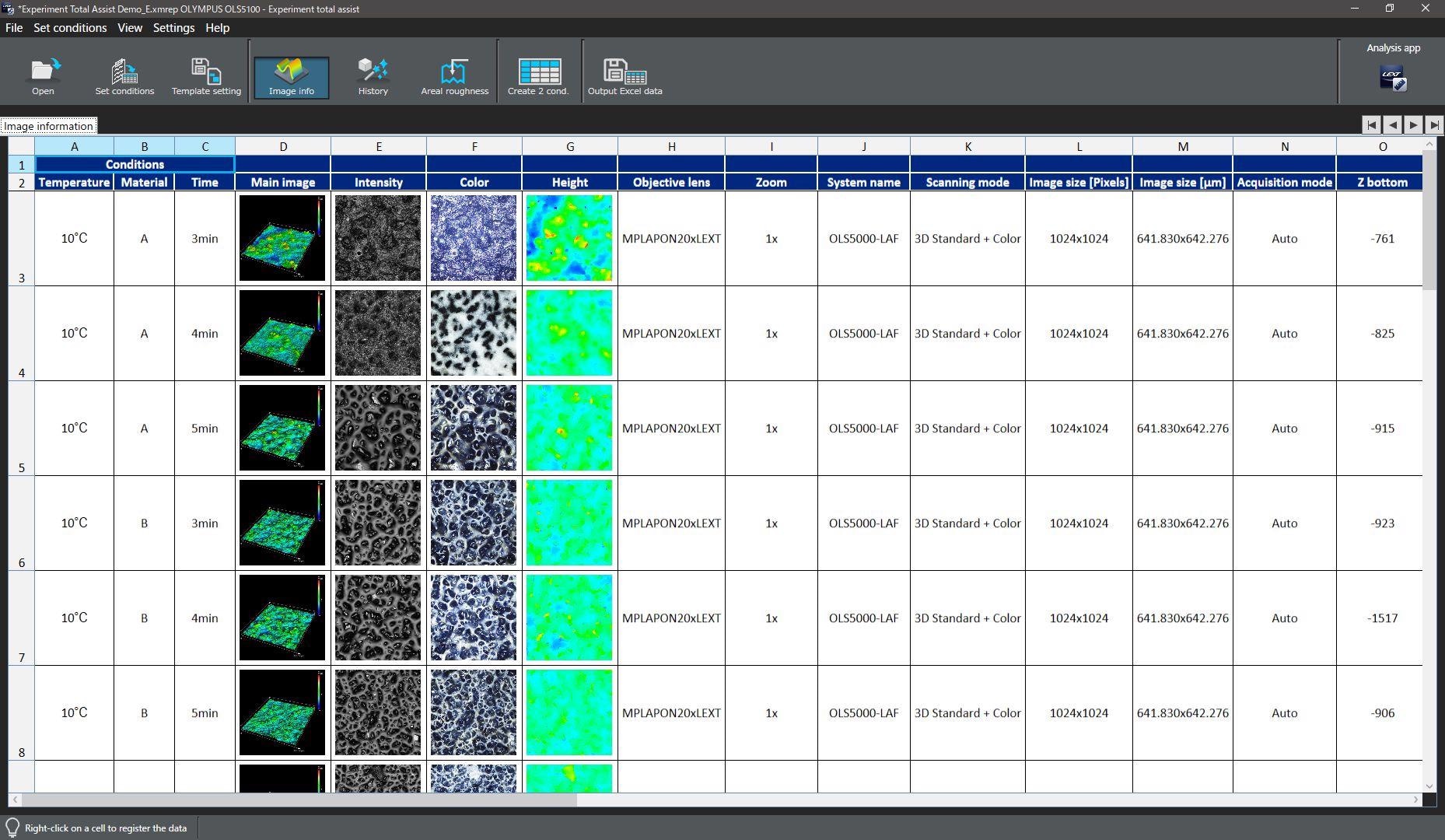

Users will likely be taking the same sample and measuring this over several days at different intervals. The Smart Experiment Manager allows users to input design values, including details about the different samples being tested and the number of intervals recorded for each sample. The software will then guide users through the process of capturing those images.

Notably, the next operator can take over the experiment, and the software will ensure they continue from the appropriate point, highlighting the interval or timeframe capture of the next image step.

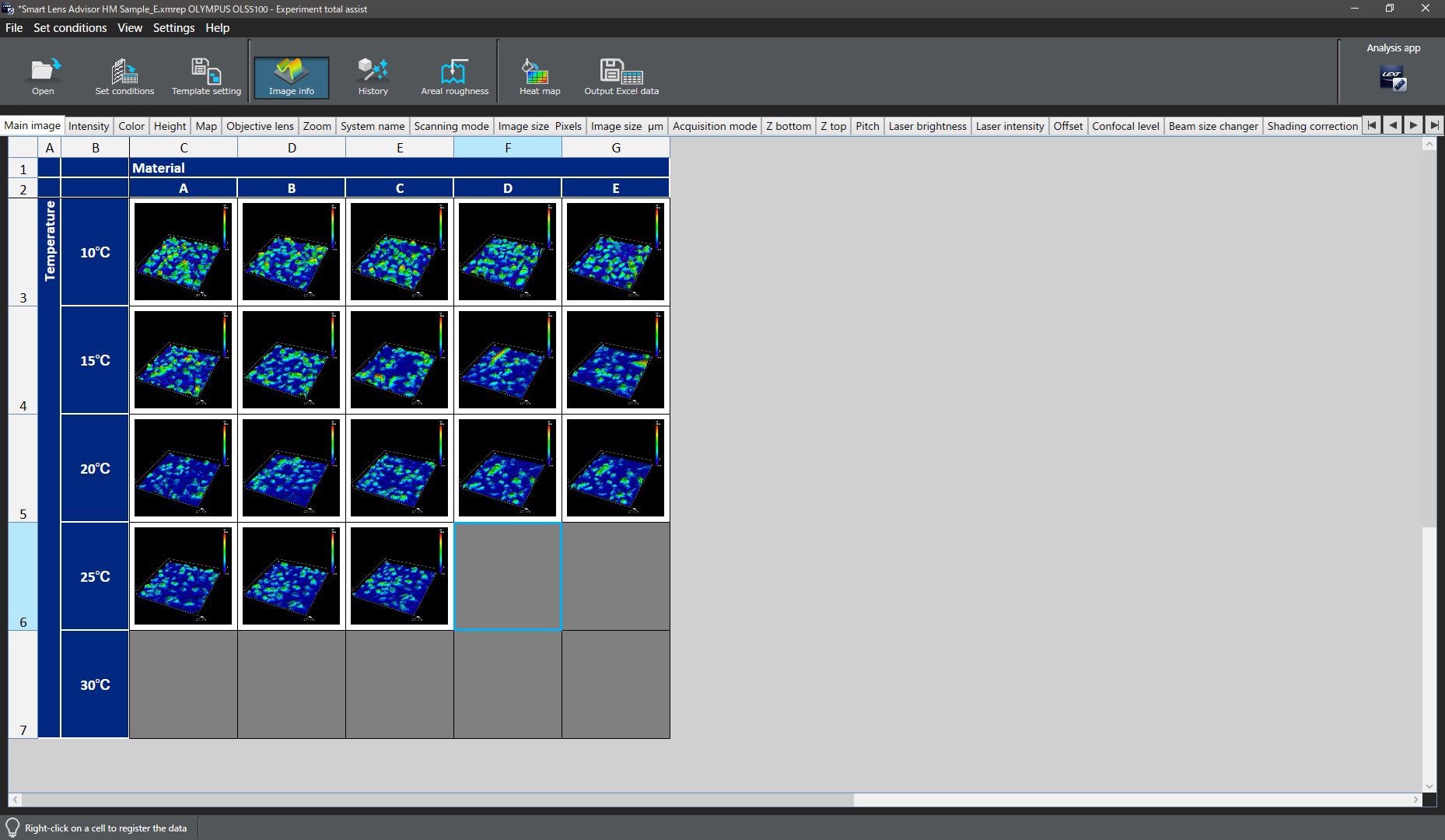

Once the experiment testing is complete, the Smart Experiment Manager will provide the correlated data and a heat map, showing how the surface roughness changes between different samples or as a result of different types of wear tests at different intervals.

The Smart Experiment Manager software helps minimize input errors because it provides a guided workflow, showing the next operator exactly what is required for the next step in the experiment.

It also makes it easy for users to look at the data over time and filter it by key parameters, such as material, coating, timeframe or wear level.

Image Credit: Evident

Which industries will benefit the most from the Smart Experiment Manager?

The most typical applications for this software are in failure analysis or quality assurance labs.

In failure analysis, the lab will apply a set of conditions to replicate or induce failure under certain conditions. Quality testing labs, on the other hand, may be looking to assess the quality of key features, much like the coating example I’ve already discussed.

Image Credit: Evident

How is the Smart Experiment Manager different from previous software packages and other products currently available on the market?

Typical systems on the market offered a range of testing abilities, but the user was required to calculate and correlate data offline, either in a document or on paper.

Users would have to compile their own charts, go through their workflow manually, save their images into specific folders according to sample and time, etc. This degree of manual interaction made the whole process much more difficult and added a significant risk of user error.

The Smart Experiment Manager has significantly streamlined this process. The software now guides the operator through the process, keeping track of the data. It even works between different operators.

The software helps minimize human error in the workflow, making data analysis easier because the data is correlated together and available via a single interface. This includes all the data from their measurements as well as analytical information like dates, timeframes and steps. It is also easy for users to export this information to various formats.

Other systems are available for specific high-end lab equipment, but to my knowledge, no high-end imaging systems for surface metrology offer a similar software interface.

Image Credit: Evident

How does the Smart Experiment Manager work in conjunction with the LEXT OLS5100 microscrope?

The LEXT laser scanning confocal microscope is the base unit for image capturing and the acquisition of high-resolution data. This unit and the base software package are required to acquire images, process the data and run the background measurements.

The Smart Experiment Manager is really an additional interface for this instrument and comes bundled with the analytical software package provided with the system, meaning these two systems integrate seamlessly.

For example, when a user defines their experiment and presses the button to measure the next step, the Smart Experiment Manager will automatically switch back to the analytical software and open the appropriate measurement tool so that the user can capture whatever data they need to.

The Smart Experiment Manager has been designed to work in conjunction with the instrument’s standard measuring software, interfacing back and forth as required to guide the user through the whole process.

Image Credit: Evident

Looking to the future, are there any applications or industries that could benefit from this software that perhaps do not make use of this currently?

Smaller labs that are looking to use very high-resolution imaging to perform quality testing would very much benefit from this system.

A lot of smaller companies have additional quality assurance needs because their products are new or still in development. A system like this provides those companies with a flexible multi-use tool with the ability to run experiments and acquire quantitative data on their product as they are developing it.

Larger labs tend to have access to quality testing via existing systems and routines, but smaller companies that have to create these quality assurance workflows from scratch can really benefit from a multi-use system featuring the Smart Experiment Manager because it can help them develop streamlined workflows and it can be used in a lot of other microscope imaging applications.

About Robert Bellinger

Robert Bellinger has been an Evident employee for over 16 years. As Product Applications Manager, he provides application support for Evident industrial microscope systems in the US, Canada, and Latin America.

About Evident Corporation

Evident is passionate about creating customer-driven solutions for the medical, life sciences, and industrial equipment industries. For more than 100 years, Evident has focused on making people’s lives healthier, safer and more fulfilling by helping to detect, prevent, and treat disease; furthering scientific research; and ensuring public safety.

Evident's range from industrial microscopes and videoscopes to nondestructive testing technology and X-ray analyzers. These products are widely used for quality control, inspection, and measurement applications. Serving customers in fields such as manufacturing, maintenance, and environment and natural resources, Olympus technology contributes to the quality of products and adds to the safety of industrial infrastructure and facilities. For more information, visit https://www.evidentscientific.com/en/.

Solution areas:

- Aerospace

- Energy

- Electronics

- Education

- Inspection

- Material Science

- Medical Device

- Mining

- Petroleum

- Semiconductor

- Quality Control

- Research and Development

Evident's products include:

- Laser Confocal Microscopes

- Digital Microscopes

- Semiconductor & Flat Panel Display Inspection Microscopes

- Upright Metallurgical Microscopes

- Inverted Metallurgical Microscopes

- Modular Microscopes

- Polarizing Microscopes

- Measuring Microscopes

- Stereo Microscopes

- Digital Microscopes

- Objective Lenses

- Digital Cameras

- Image Analysis Software

Toll Free : +1 800-446-5967

This information has been sourced, reviewed and adapted from materials provided by Evident - Industrial Microscopy.

For more information on this source, please visit https://www.evidentscientific.com/en/.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.