Natural gas use continues to grow on a global scale. Natural gas is a reliable power source and is typically less expensive than other fossil fuels. Natural gas also burns cleaner than other fossil fuels, making it appealing from an environmental perspective.

A report by McKinsey predicted that gas will be the fossil fuel exhibiting the largest growth rates, increasing by 0.9 percent from 2020 to 2035. It is also the only fossil fuel source anticipated to continue to grow beyond 2030, expected to peak in 2037.1

Gazprom - the global energy company - estimated that worldwide gas consumption is expected to rise by 1.3 trillion cubic meters, surpassing 5.3 trillion cubic meters by 2040.2

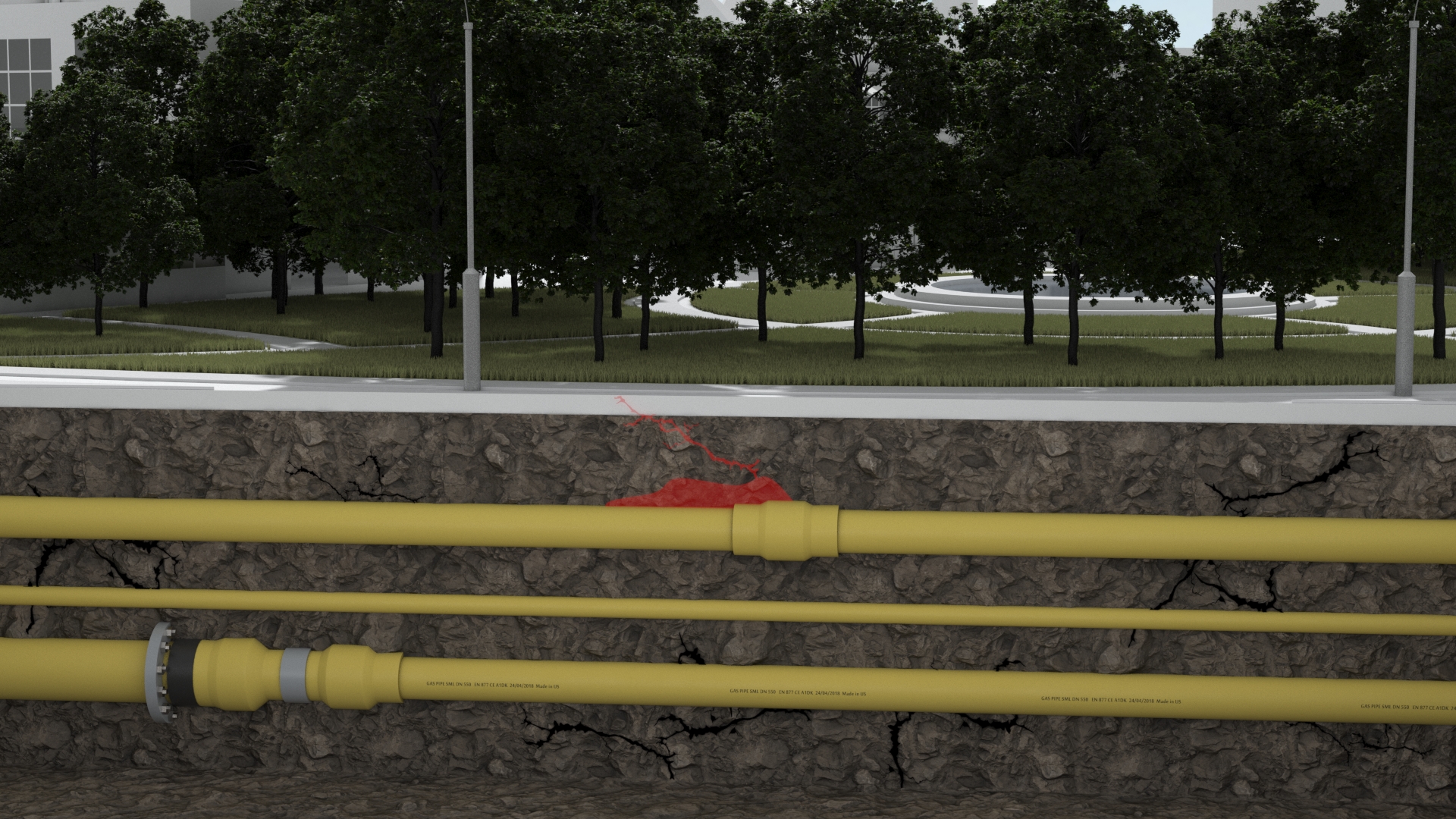

Pipelines represent the cornerstone of gas distribution, and these are typically considered cost-effective and safe means of transporting natural gas.

Gas pipeline leaks have the potential to occur at any point in the network, ranging from well collection systems to pipelines found under buildings and streets. Leaks can be caused by a wide range of factors, such as:

- Accidents during excavations, which may lead to the rupturing, nicking or puncturing of one or more pipelines

- Heavy materials or equipment being placed over buried pipelines

- Water main breaks, causing weakness in roads and pavements

- The excess accumulation of ice and snow on meters, gas pipes or gas appliance exhaust and combustion air vents

- A fire or explosion occurring close to a pipeline

- Too little or too much pressure in the gas system

- Equipment corrosion or failure

- Natural disasters, including earthquakes, floods or hurricanes

Implications of Gas Leaks

The impact of gas leaks should not be underestimated. They can lead to significant safety, environmental and cost implications.

Safety Implications

In some instances, serious gas leaks can cause injuries and fatalities. A notable example of this was in October 2020 when a gas line explosion injured 28 and killed three people in Thailand.

The blast originated from a natural gas line in Samut Prakan, southeast of Bangkok, that was operated by PTT PCL – a state owned oil and gas company.3

Gas leaks can also present a significant risk to the wider community. Examples include the 2010 San Bruno pipeline explosion in the USA and the 2005 Buncefield gas storage facility explosion in the UK. These incidents serve to highlight the risks that the escape of explosive gases and vapors has on communities.

Environmental Implications

Natural gas leaks have serious adverse effects on the environment, with methane released into the atmosphere prior to being burned acting as a major contributor to global warming due to its ability to trap heat in the atmosphere.

Pipeline leaks are a common source of these methane leaks. The International Energy Agency (IEA) highlights that methane emissions from the oil and gas industry accounted for approximately 70 Mt in 2020 – the equivalent of 5% of global energy-related greenhouse gas emissions.4

Cost Implications

From a financial perspective, leaking gas from pipelines causes billions of dollars of lost revenue every year, both in terms of direct product loss and the cost and time implications of replacing this.

Importance of Pipeline Maintenance

The complete elimination of gas leaks is virtually impossible, but the implementation of robust pipeline maintenance strategies can help to reduce these.

It is important to consider right-of-way clearing when initially laying pipelines, and debris should be removed to help avoid the risk of pipeline damage.

Pipelines should also undergo stringent and comprehensive testing; for example, hydrostatic testing can ensure that the pipes perform adequately under pressure.

It is important that pipelines are routinely monitored for signs of corrosion. This should also include the implementation of a proactive inspection and maintenance schedule to help maintain pipelines and avoid gas leaks.

Drawbacks of Traditional Gas Leak Detection

Pipeline maintenance is important, but gas leak detection systems also have a critical role to play in helping to determine the source of a potential leak. Conventional approaches to leak detection can be slow and inaccurate, however, offering only limited sensitivity to leaks.

Technicians using conventional methods are required to walk the area that is being inspected, employing handheld detectors that can take extended periods of time to calibrate once activated onsite.

These systems only test the air only every few seconds, meaning that the technician is required to move slowly and methodically throughout the suspected leak site. The technician is also required to input results manually into reporting systems, increasing the amount of time taken to complete a survey.

Next-Generation Gas Leak Detection

Advancements in sensing, analytics and mobile technology have led to the development of a new generation of gas leak detection solutions offering significantly better performance than traditional methods.

These systems are able to respond in less than a second, offering technicians the capacity to detect methane from natural gas leaks at concentrations of 1 part per billion (ppb) or less. Using these advanced instruments, investigators are able to detect large, small and even hidden leaks despite being far away from their sources.

Mobile gas leak detection solutions from ABB employ powerful laser-based sensors, GPS technology and advanced analytical software to substantially enhance the accuracy and speed of gas leak identification and location.

This technology is more than 1,000 times more sensitive than previous approaches. This comparison can be likened to the difference in clarity between contemporary high-definition TVs and classic black and white TV sets.

Image Credit: ABB Measurement & Analytics

ABB’s MobileGuard™ utilizes a GPS module, an onboard ultrasonic anemometer to measure wind velocity and advanced innovative analytics to detect, locate and accurately determine the size of natural gas leaks.

The technology is able to accomplish this while covering 10 to 25 times more land area per hour than conventional methods.

ABB’s platform is designed to detect ethane, which is found primarily in thermogenic pipeline gas, along with methane. This means it is able to eliminate false positives that are typically linked to biogenic sources of methane, for example, sewage and animal waste.

The MobileGuard™ system can detect methane from leaks from up to 300 feet away from a vehicle moving at 55 mph.

Similar solutions are available for detecting, mapping and quantifying leaks from a drone-based system (HoverGuard™), from technicians working on foot (MicroGuard™) and via stationary applications at key locations (EverGuard™).

Image Credit: ABB Measurement & Analytics

ABB’s complete portfolio of solutions can be securely connected to cloud-based systems, enabling the immediate sharing of comprehensive results and data on leak locations and sizes in real-time.

This distinct combination of accuracy, speed and operational efficiency empowers pipeline operators and service providers to streamline their operations while continuing to meet the increasing demand for fast, accurate and transparent data.

Most crucially, each of these new solutions based on ABB’s established and widely regarded LGR-ICOS technology is being employed by companies across the US and worldwide at all stages of the natural gas value chain.

Regulation

Governments and industry bodies have come to recognize the seriousness of gas leaks and are continually striving to address the issue.

The Protecting Our Infrastructure of Pipelines and Enhancing Safety (PIPES) Act of 2020 was signed into law in the US on 27 December 2020.

The Act requires gas pipeline operators to employ comprehensive and advanced leak detection technologies to implement robust leak detection and repair programs suitable for protecting pipeline safety and the environment.

Similar legislation is being implemented in countries and regions worldwide, prompting operators to use the most effective technologies to locate, measure, intervene and manage the risk of natural gas leaks throughout the distribution network.

Continuous Improvement

The advent of the digital age has significantly altered natural gas leak detection practices, facilitating exponential improvements in terms of accuracy, sensitivity, speed and cost-effectiveness.

While it is impossible to eliminate gas leaks, companies should strive to employ the most advanced gas leak detection technology available to address leaks as quickly and safely as possible.

References

- Global gas outlook to 2050 | McKinsey

- Natural gas demand poised for long-term growth (gazprom.com)

- https://www.hazardexonthenet.net/article/181562/Gas-line-explosion-kills-three--injures-28-in-Thailand.aspx

- www.iea.org/reports/driving-down-methane-leaks-from-the-oil-and-gas-industry

This information has been sourced, reviewed and adapted from materials provided by ABB Measurement & Analytics.

For more information on this source, please visit ABB Measurement & Analytics.