With the worldly population reaching an all-time high, the demand for food has been growing exponentially. This escalation in demand is causing the food industry to also grow worldwide, resulting in the industry witnessing various types of challenges and complexities.

Image Credit: Vladimir Nenezic/Shutterstock.com

One problem that has been lingering in the food industry since the dawn of time is quality control of the food. Food is a necessity for all human beings, which is why food processors uphold great responsibility of being immensely concerned about the excellence in the food supply.

Food Sorting

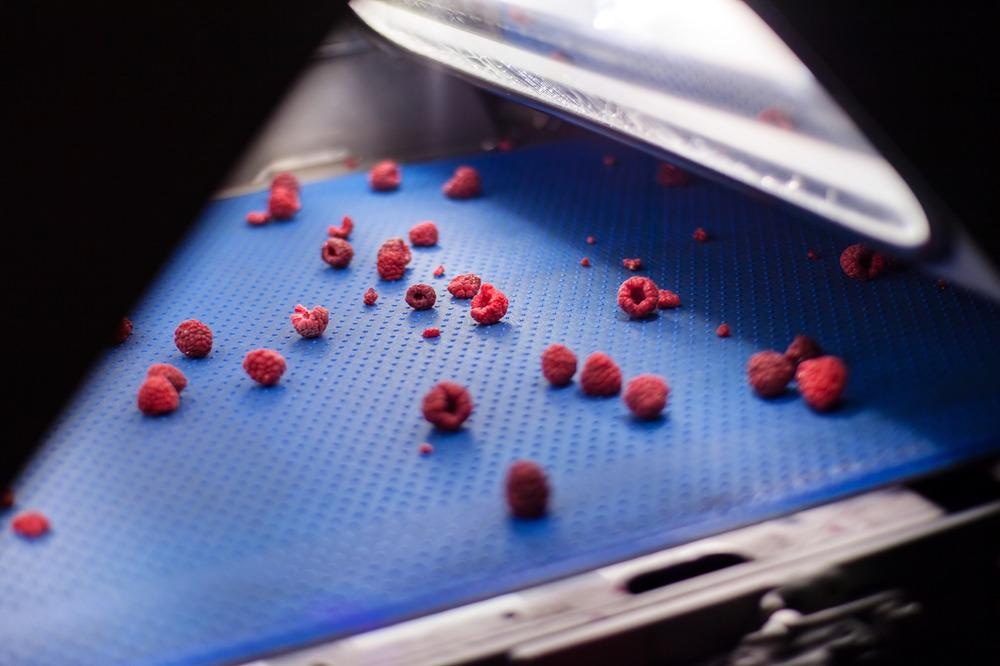

To ensure food of satisfactory quality is being produced, a process called “food sorting” is incorporated at numerous points in the food supply chain. Food sorting is the process of removal of foreign objects from food. In this world of machines, the process has also been automated to a great degree in the food industry. Amongst the list of many tools and techniques that are commonly used, the laser is one of the front runners when it comes to industrial food sorting.

Past Limitations

Food safety has always been a matter of great concern for the public due to its very direct relation to human health. Before the inclusion of machines and technology in the lives of mankind, hygiene and quality control by food sorting used to be done manually for the most part i.e., using hands. The main criteria through which the food was sorted included color, size, shape, and weight.

The unwanted materials were removed from the eatery items by judging the above four properties. The main drawback to this method, however, was the human limitations and inaccuracies. For example, the foreign objects that would be small enough to be invisible to the naked eye would be ignored in the process including a foreign object of a similar color or shape.

Latest Food Sorters

In the modern world, processors are progressively replacing manual inspection with electronic ordering sorting machines to maximize the elimination of unwanted materials. The digital sorters consist of various components and work on different working principles.

Some sorters use camera systems, others use lasers, and still others utilize a hybrid system of both to assess merchandise via a top view, a bottom view, or maybe both. This is dependent on the type of food and business purposes. However, the basic operational elements such as food carrier and handling system, as well as sensors, etc. are present in all systems.

Advantages and Utilization of Laser Emitters

The limitations to manual sorting were acknowledged and it was soon realized that the process of food sorting needed automation. Thus, alongside other tools, the usage of laser emitters in food sorting was recognized to be one of the more effective, consistent, and reliable options. Along with that, it also proved to be more cost-efficient when compared to the overall costs of the labor involved in manual sorting.

Optical Sorter Animation - how it works

Optical Food Sorting. OdenbergEngineering/Youtube.com

The laser is mainly used to sort food items based on the properties of their structures. For this reason, they can easily be used to detect a vast number of foreign objects in/on food items.

One major benefit of using lasers for sorting is the fact that lasers are also capable of determining the chlorophyll inside the material, and this allows easy sorting of different plant-based food materials even if the color, size, shape, weight, etc of the foreign object is undetectable. For example, if a laser sorter is fluorescence-sensing, it can be used to identify tiny bugs that may otherwise be camouflaged on certain plant-based food.

Limitations of Laser Emitters

For the past couple of years, the technology in food sorting due to laser emitters amongst others has skyrocketed. The food quality has elevated greatly from that from a few decades ago. Despite these advancements, there are some underlying problems and complexities that exist currently.

Studies have shown that the lasers can be made to operate in light from the visible range, the infrared range, and the ultraviolet range only. Laser emitters are usually used alongside high-quality cameras that, like the manual method but much better, sort the food based on its color, size, shape, and weight.

Future of Laser Emitters in Food Sorting

When it comes to laser emitters, the future demands further progressive ways of detecting a foreign object on an edible item. Thus, the main prediction in the laser technology is that it would be able to distinguish between two objects as effectively as possible by incorporating more laser frequencies.

As it stands, food sorting systems are not only complicated to operate but also expensive to maintain.

In the coming years, a lot of progress is expected to be made in food sorting, such as the technology advancing so that inclusion of foreign objects in food approaches 0%, and the sorters becoming capable of determining the quality and separating food items that are below the acceptable quality standard.

Clear-Welding Polymers with Laser Technology

References and Further Reading

Jaimeen, S. (2017). Food Sorting and Grading Machine. International Journal of Engineering Research. https://www.academia.edu/31659940/Food_Sorting_and_Grading_Machine

Jamali, A., & Misman, F. A. (2021). Food Waste Management: A Case Study of the Employment of Artificial Intelligence for Sorting Technique (Vol. 1st). Apple Academic Press. https://www.taylorfrancis.com/chapters/edit/10.1201/9781003144748-15/food-waste-management-case-study-employment-artificial-intelligence-sorting-technique-jamali-misman

Key Technology. Food Sorting Technology 2020: An In-Depth Look Into an Evolving Industry. https://www.key.net/en/wp-content/uploads/2018/12/Sorting_2020_eBook_PDF.pdf

Key Technology. Understanding How Electronic Sorting Technology Helps Maximize Food Safety. https://www.key.net/en/wp-content/uploads/2018/12/WP_Sorting-Food-Safety_PDF.pdf

monocrom. Laser Technologies for Sorting in Food Production. Retrieved from monocrom: https://www.monocrom.com/en/applications/industrial/sorting-lasers-food-industry/

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.