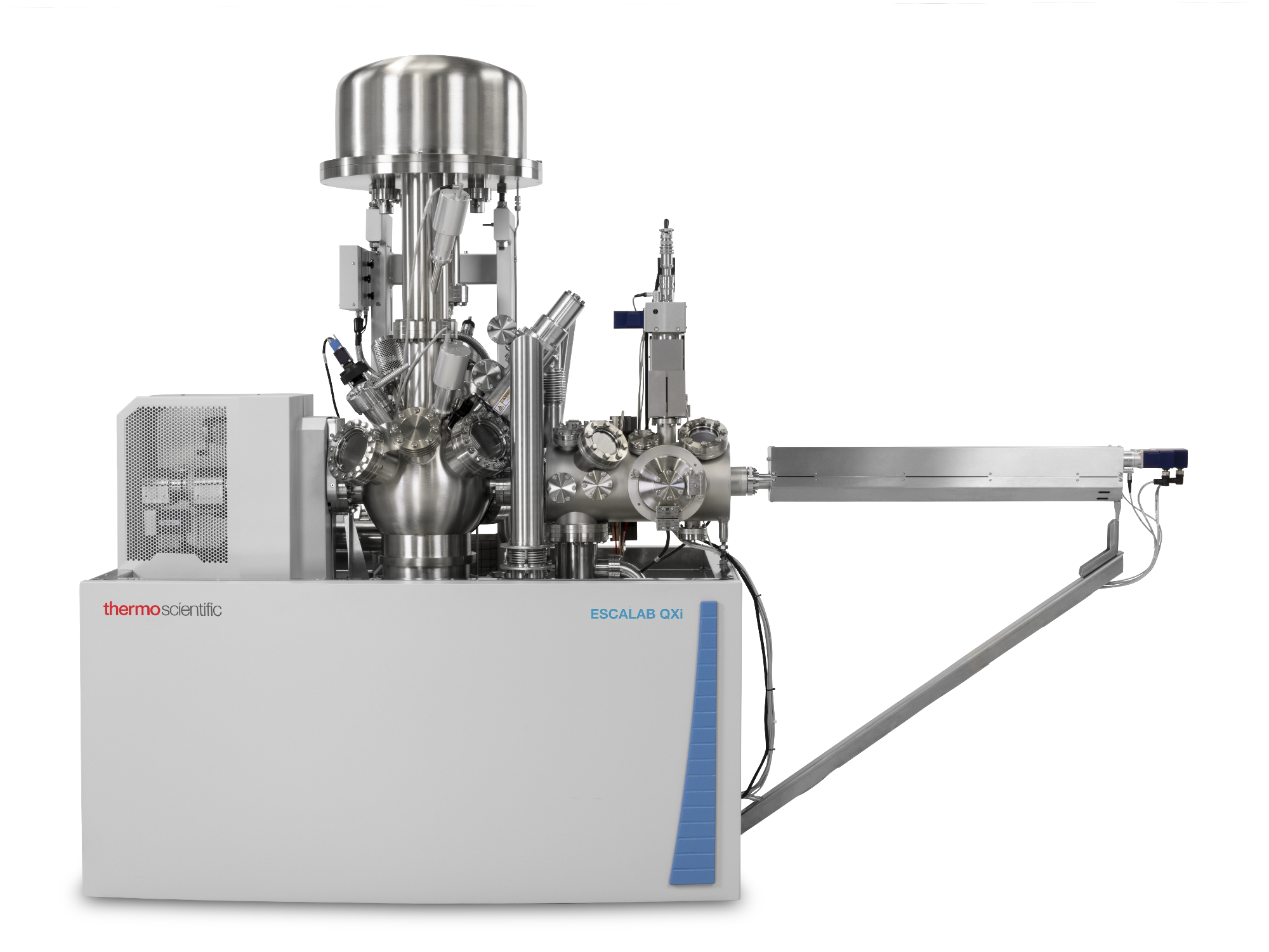

In this interview, AZoM talks to Tim Nunney, Applications Development & Marketing Manager from Thermo Scientific Surface Analysis and Microanalysis about the new Thermo Scientific™ ESCALAB™ QXi X-ray Photoelectron Spectroscopy (XPS) Microprobe. This new XPS Microprobe offers sensitivity and resolution, with potential applications spanning numerous industries.

Could you describe the main functions of the Thermo Scientific™ ESCALAB™ QXi X-ray Photoelectron Spectroscopy (XPS) Microprobe?

The ESCALAB QXi is the newest generation of our long-standing ESCALAB product line, which has been at the forefront of surface analysis for over forty years. The guiding principles of the new instrument are the same as they were at the start; to help scientists advance their research as efficiently and effectively as possible, without compromising system performance.

The standard configuration includes everything necessary for X-ray photoelectron spectroscopy (XPS): a micro-focusing monochromated X-ray source, highly efficient electron optics, the unique dual detector system for spectroscopy and XPS imaging, plus an ion source for sample cleaning and depth profiling and charge neutralization for analyzing insulating samples.

As well as the tools for XPS, two additional analytical techniques are included as standard: ion scattering spectroscopy (ISS, also known as LEIS) and reflected electron energy loss spectroscopy (REELS). Other options can be added to the system, including the MAGCIS dual mode ion source, which is essential for depth profiling materials that are damaged by monatomic ion beams such as polymers and oxides, extra sources for AES, UPS and HAXPS and an automated sample exchange system, which enables even faster sample throughput.

All of these technologies come together to give scientists the tools they need to understand the chemistry of surfaces and interfaces, whether they are trying to engineer new electrodes for better batteries or determine the reasons for a failure at an interface.

Image Credit: ESCALAB QXi X-ray Photoelectron Spectrometer (XPS) Microprobe - Multi-technique surface analysis instrument with high-resolution XPS spectroscopy and imaging

Why are high resolution and high sensitivity important for advanced analytical laboratory research?

The strength of X-ray photoelectron spectroscopy as a technique for understanding materials lies in its surface selectivity and its ability to go beyond the elemental-only information delivered by other methods and give quantitative chemical state measurements of the surface or interface composition. These different chemical states appear spectroscopically as different peaks, and the resolving power of the spectrometer is only one part of how easily they can be deconvoluted.

The sensitivity of the spectrometer helps remove uncertainty from measurements by improving the signal-to-noise in the data, making it easier to identify low concentration components. Having good sensitivity also helps with identifying chemical states, as running in higher resolution modes reduces the signal through the spectrometer. Thus, by having higher sensitivity, these modes can be run with less of a penalty in terms of acquisition time.

The ESCALAB QXi is optimized to deliver excellent performance with both high sensitivity and high resolution. The electron optics are optimized to maximize their collection efficiency without having to drive the X-ray source to high powers, which can damage sensitive materials.

The ESCALAB QXi XPS Microprobe employs different methods to define the XPS analysis area. What are these methods, and what are their advantages?

As the user of the ESCALAB changes the area size that they wish to investigate, they are guided to use the best method for achieving optimal results. In the large area regime (> 200 µm), the analysis area is defined by the size of the X-ray spot size. The operator uses the microfocus X-ray monochromator to set the size of the X-ray spot size to match with the feature of interest, and this ensures the maximum signal is achieved.

For smaller features, the clever design of the analyzer is used to define the analysis area, enabling spectroscopy from features smaller than 5 µm. This high resolution method, known as “XPS parallel imaging,” is fast and allows spectra to be obtained from small features with ease due to the fact that signal from all positions in the field of view are collected simultaneously (unlike serial imaging where each pixel is collected one-after-the-other).

Animation: Thermo Scientific ESCALAB QXi Microprobe Auto Sample Transfer

What are some optional analysis techniques this system can accomplish apart from the included X-ray photoelectron spectroscopy, reflected electron energy loss spectroscopy and ion scattering spectroscopy?

As well as the standard techniques (XPS, ISS, REELS), the system can be equipped with other sources to add further analytical capabilities. These include a UV source for UV photoelectron spectroscopy (UPS), a related technique to XPS, which is used to investigate the valence electronic structure of materials.

UPS is particularly useful for understanding changes to properties like the work function and investigating the highest occupied molecular orbitals of materials like OLEDs. In this way, it’s a nice partner to REELS which probes the unoccupied states. It is also possible to fit a scanning field emission electron source (a FEG source) to the instrument, which can be used for secondary electron imaging, and Auger electron spectroscopy (AES). With the addition of an X-ray detector, it is also possible to do EDS with this source. AES can be useful for certain types of samples, such as semiconductor bond pads, to perform surface analysis with higher spatial resolution than is possible with XPS.

It is also possible to add additional X-ray sources to the system, such as a monochromated Ag L-alpha X-ray source or a range of non-monochromated options, including Mg, Zr and Ti. With the exception of the Mg source, all of these X-ray sources have energies that are higher than the standard Al K-alpha source, which can allow access to deeper core levels (e.g., Si 1s) or increase the maximum depth that a particular signal is being collected from.

It’s also possible to add techniques such as secondary ion mass spectroscopy (SIMS) or inverse photoemission spectroscopy (IPES) to the instrument. The platform’s open nature even makes it possible to interface with other pieces of equipment for very specific requirements.

Dr. Hsiang-Han Tseng and Dr. Robin Simpson. Image Credit: Thermo Fisher Scientific

How does the ESCALAB QXi XPS Microprobe streamline laboratory workflows, improve data acquisition and produce high quality results?

Two new features on the instrument help with streamlining workflows to improve sample throughput. The first is the option to add the automated sample exchange (ASE) system. This includes full computer control of sample loading and unloading from the three-position sample parking location in the load-lock chamber, interfacing with the standard computer control of the sample stage in the analysis chamber. ASE allows the unattended exchange of sample carriers, meaning that experiments can keep running on the system 24/7, maximizing the productivity of the system.

The second feature is the update of our Avantage software to version 6. This not only adds the control for ASE, but also the ability to create and queue up experiments while the system is acquiring data on the current sample set. Avantage v6 also features integration with our Maps software to facilitate correlation of ESCALAB data with SEM imaging and analytics, improvements to data visualization and new data processing capabilities. All of these new features help with acquiring, processing and understanding your data so that you can achieve high quality results as efficiently as possible.

Can you give some application examples of how the ESCALAB QXi can be applied to materials research?

XPS as a technique is used for the analysis of samples from a wide range of applications and industries. The surface of a material is, after all, the part that is going to interact substantially with the environment around it, whether intentionally or not.Thus, understanding it is going to be very important. As an example, with the demand to generate electricity through renewable methods, developing better photovoltaics is a key research area. The range of standard techniques on the ESCALAB QXi (XPS, ISS and REELS) can be used to understand candidate materials.

Firstly XPS can be used to check the composition and assess whether the chemistry is as expected. ISS can be used to confirm that the termination of the surface is as expected, with the increased surface selectivity compared to XPS. Finally, REELS can be used to help understand electronics properties, which can have an impact on the efficiency of the material. Of course, the other techniques that can be added, like UPS, can also add significant insights, meaning that the ESCALAB QXi can be used to get a large volume of data in a short amount of time from co-incident positions on the sample.

So from designing new devices for energy generation and storage to issues of understanding how surfaces can be prepared to inhibit corrosion, to preparing ever more efficient catalysts, or treating polymers to create safe surfaces for biomedical devices, there is an ever-expanding list of tasks that XPS assist in understanding, and the ESCALAB is one of the leading instruments to do this.

About Dr. Tim Nunney

Dr. Tim Nunney is Applications Development & Marketing Manager for the Thermo Scientific Surface Analysis (X-ray photoelectron spectroscopy) product line. His role involves all aspects of product marketing, including managing the applications team, customer evaluations, product development and commercial support.

He has been with Thermo Fisher Scientific since 2004, previously holding positions as an applications scientist, and in the operations group. Prior to joining Thermo Fisher Scientific, Tim worked as a post-doctoral research fellow at the University of Southampton, investigating the dynamics of molecular dissociation on metal surfaces. He completed a Ph.D. in Surface Science at the University of Liverpool, an Msc in Surface Science & Catalysis at the University of Liverpool, and a BSc (Hons) in Chemistry from the University of Nottingham.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.