The value of data is widely recognized and continues to grow by the day. Despite its benefits, the significant value of NIR calibration data is often a barrier to switching from an unsuitable vendor or upgrading older spectrometers.

This necessary spectral data is linked to reference chemistry, often spanning several production runs and crop years.

This article features a case study highlighting the advantages of and approaches to transferring calibration databases between instruments and vendor platforms.

Doing so allows users to benefit from the most up-to-date latest technology while partnering with a supplier that is able to accommodate the full range of food and agricultural analysis needs.

Upgrading to a New High-Performance FT-NIR Analyzer

The FT 9700™ from PerkinElmer provides many advantages, particularly compared to the classic scanning monochromator and the FT-NIR instruments developed in the 1980s or 1990s.

Figure 1. FT 9700 NIR Analyzer. Image Credit: PerkinElmer Food Safety and Quality

This newly launched high-performance Fourier Transform NIR instrument has been built on the robust foundations of the PerkinElmer DynaScan™ interferometer.

The FT 9700 is capable of analyzing a sample in 30 seconds. Its temperature-stabilized InGaAs detector covers the 700 nm - 2500 nm (ca 14700 - 4000 cm-1) wavelength region. The instrument analyzes samples via an up-view NIR reflectance module and sapphire glass bottom cups rotated by a magnetically coupled spinner.

The FT 9700 standalone analyzer is interfaced and driven by a Windows 10 computer. It is operated via the ResultsPlus touchscreen user interface, and a number of systems can be networked via the NetPlus™ cloud solution.

Networking systems in this way offers a range of benefits, including remote maintenance, calibration support, administration and report generation.

A contemporary FT-NIR technology platform like the FT 9700 offers a distinct combination of improved technical performance, enhanced calibration transferability, and the option to employ sophisticated calibration algorithms; for example, the PerkinElmer-developed Hongis Regression™ (HR) or Artificial Neural Network (ANN).

This instrument also offers an array of benefits linked to its user-friendly interface, flexibility, straightforward sample handling, integrated computer and accessible touchscreen operation.

Achieving NIR Data Transfer Between Instruments

It is extremely valuable to reuse historical NIR data that was collected using an older NIR platform as the basis of calibrations for a new platform.

Transferring calibration data removes any requirement to essentially start over from the beginning, dramatically streamlining and speeding up the implementation of the current technology.

Studies have investigated calibration transfers based on data transfer between dispersive scanning monochromator and non-PerkinElmer branded FT-NIR instruments to the new FT 9700 analyzer.

Successful model transfers have been shown to be possible between a number of NIR models from a range of vendors, including both older and more current NIR instruments. Sample matrices for these transfers have been comprised of an array of forages, grains, other feed materials, fermentation slurries, dairy powders and more.

The calibration transfer process requires a comprehensive analysis of the actual wavelength scale of the older NIR units. Before developing and implementing the new calibrations, it is also necessary to realign existing data.

The realignment of existing data generally involves the following steps:

- Analysis of a set of common samples on both the old NIR unit and the FT 9700. These should include:

- Wavelength standard samples

- Aa set of 10-30 genuine samples (reference chemistry values are not needed)

- Realignment of an existing database with standardization to match FT 9700

- Using Unscrambler X or PerkinElmer calibration tools to develop new calibration models on standardized data

- Using a set of ~20 samples with reference values to validate the new calibrations

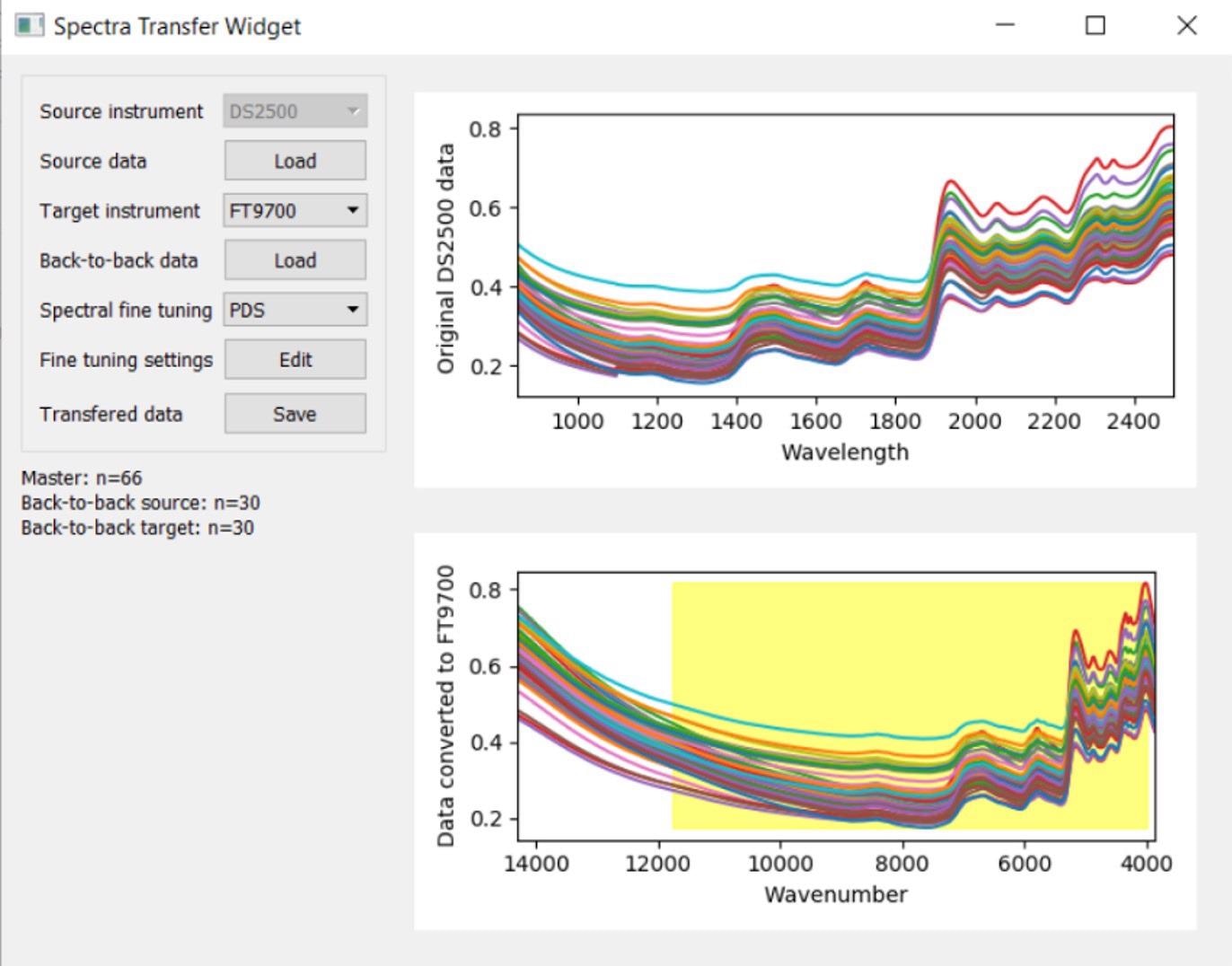

It should be noted that PerkinElmer has developed a user-friendly spectra transfer tool to facilitate this process. The tool also features various tuning and data alignment functions.

Results of the Studies

The studies’ results demonstrated the possibility of successful calibration transfer. This was found to be simple and quick, so long as the old platform covered a comparable wavelength range as the FT 9700.

The transfers were successful irrespective of whether the original data was collected on specific scanning monochromator instruments or other FT-NIR models. Prediction accuracy following transfer was found to be almost identical to performance on the older platforms.

Figure 2. Spectra graph of data transferred from dispersive unit to new FT 9700 analyzer. Image Credit: PerkinElmer Food Safety and Quality

Final accuracy was found to be limited by the initial spectra quality, the data transfer process and the original data’s reference value accuracy.

The addition of samples collected on the FT 9700 to calibrations was found to be beneficial in terms o further improving accuracy and fully benefiting from the modern FT-NIR unit’s capabilities.

Adding these samples made it possible to leverage the benefits of improved spectra quality, helping to ensure that advanced calibration types such as ANN and HR were able to perform at their best.

Table 1 displays a series of calibration results on FT 9700 models using dry grass silage and forage calibration models from databases that have been collected using dispersive scanning monochromator instruments. The transfer of these examples was completed by Walloon Agricultural Research Centre, CRA-W, Gembloux, Belgium.

Table 1. Calibration performance example, transferring dry grass and forage calibrations from scanning monochromator unit collected database to new FT-NIR technology based FT 9700. Source: PerkinElmer Food Safety and Quality

| Constituent |

N |

Range % |

RSQ |

SEC |

SECV |

| Dry matter |

2835 |

87.9 - 98.5 |

0,74 |

0,89 |

0,90 |

| Protein |

2497 |

0.9 - 29.8 |

0,97 |

0,82 |

0,83 |

| Fiber |

1926 |

11.5 - 40.7 |

0,93 |

1,28 |

1,31 |

| Ash |

2773 |

3.4 - 17.3 |

0,85 |

0,88 |

0,90 |

| NDF |

956 |

28.6 - 67.3 |

0,95 |

1,46 |

1,54 |

| ADF |

818 |

15.3 - 40.0 |

0,95 |

0,88 |

0,94 |

| ADL |

683 |

0.0 - 4.9 |

0,89 |

0,27 |

0,30 |

| Dry Matter Digestibility |

140 |

31.8 - 103.6 |

0,97 |

2,09 |

2,44 |

| Total Soluble Sugar |

821 |

0.0 - 33.3 |

0,98 |

0,93 |

1,02 |

* Results calculated on database that Includes only 20 additional calibration samples from FT 9700.

The table’s values can be understood to be:

- N = number of sample spectra in models

- Range = lowest to the highest value of included samples

- RSQ = determination coefficient

- SEC = Standard Error of Calibration

- SECV = Standard Error of Cross-Validation estimated accuracy.

It was noted that the accuracy of transferred models was very similar to the original performance.

The Importance of Planning Ahead

Throughout the course of the study, it was highlighted that transferring existing NIR data can facilitate the rapid and straightforward generation of calibrations suitable to the FT 9700.

The study looked at hundreds of samples in historical databases, all of which were able to be used with good results.

It is important to note that effective calibration transfer requires that the spectra be acquired on a common set of samples and collected on both the old instrument and the FT 9700.

Users looking to complete this process should plan sufficiently ahead to ensure this takes place prior to the older platform being inoperable - and while this is still producing quality data.

This information has been sourced, reviewed and adapted from materials provided by PerkinElmer Food Safety and Quality.

For more information on this source, please visit PerkinElmer Food Safety and Quality.