The accurate measurement of orientations close to the grain interfaces is an essential component of investigating phase relationships and grain misorientations.

Traditionally, EBSD specimen preparation (whether mechanical or electropolishing) may bring about abrupt edges at boundaries between phases that have different polishing resistance and hardness.

Shadowing on steeply tilted EBSD samples can be a result of such topography, which can thus limit the possibilities of obtaining grain boundary information that is accurate.

This topography effect can be alleviated by broad beam ion milling at a low incidence angle.

The sample surface, after milling, normally has a somewhat undulating topography which has a smooth continuous surface across grain boundaries. This smooth continuous surface is beneficial to grain boundary characterization.

Materials and Methods

Gatan PECS™ II and EDAX Velocity™ Super EBSD Analysis System was used with APEX™ 2.0 Software.

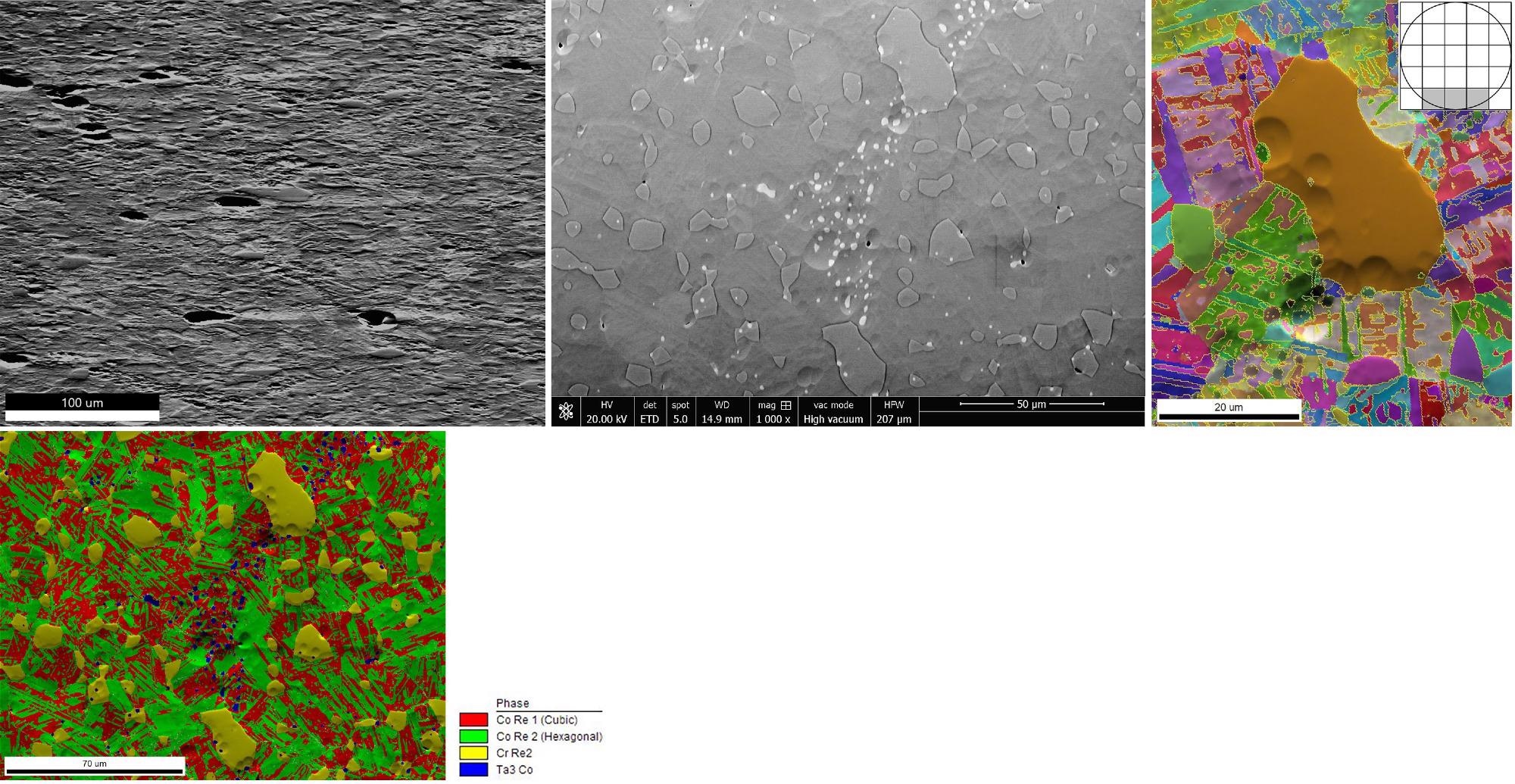

Mechanical polishing was used to prepare a multiphase CoRe alloy with Ta3Co and CrRe2 particles, which was subsequently milled for 10 minutes in the PECS II with Ar ions at a 4° incident angle at 6 kV followed by 20 minutes at 5 kV.

A rough surface with sharp discontinuities had formed at the interphase boundaries after the initial polishing. The edges of protruding grains were removed by low incident angle ion milling, and the grain boundaries were exposed for detailed analysis.

Figure 1. (top row) (left) Forescatter electron image of the mechanically polished sample in a tilted position. (center) SEM secondary electron image of the sample after ion milling (horizontal). A smooth topography across grain boundaries has replaced the sharp edges at grain and phase boundaries. (right) A detailed EBSD IPF on PRIAS™ bottom map of a large CrRe2 grain in a matrix of hexagonal and cubic CoRe grains. The PRIAS image is generated by summing the EBSD pattern intensity along a strip at the bottom of the pattern for each point and is very sensitive to topography. Yellow lines indicate phase boundaries. The grain and phase boundaries do not coincide with a topographical change anymore, and accurate analysis is possible. (bottom row) EBSD phase map on PRIAS bottom image. Image Credit: Gatan Inc.

Summary

Due to a variation in each phase’s polishing response, preparing polyphase materials can be problematic for EBSD analysis. This can often lead to unwanted topography, which in and of itself can contribute to shadowing artifacts when acquiring EBSD data.

In order to both minimize the topography and ensure an optimum surface (where all phases and grain boundaries can be successfully analyzed), road beam ion milling can be used.

This information has been sourced, reviewed and adapted from materials provided by Gatan Inc.

For more information on this source, please visit Gatan Inc.