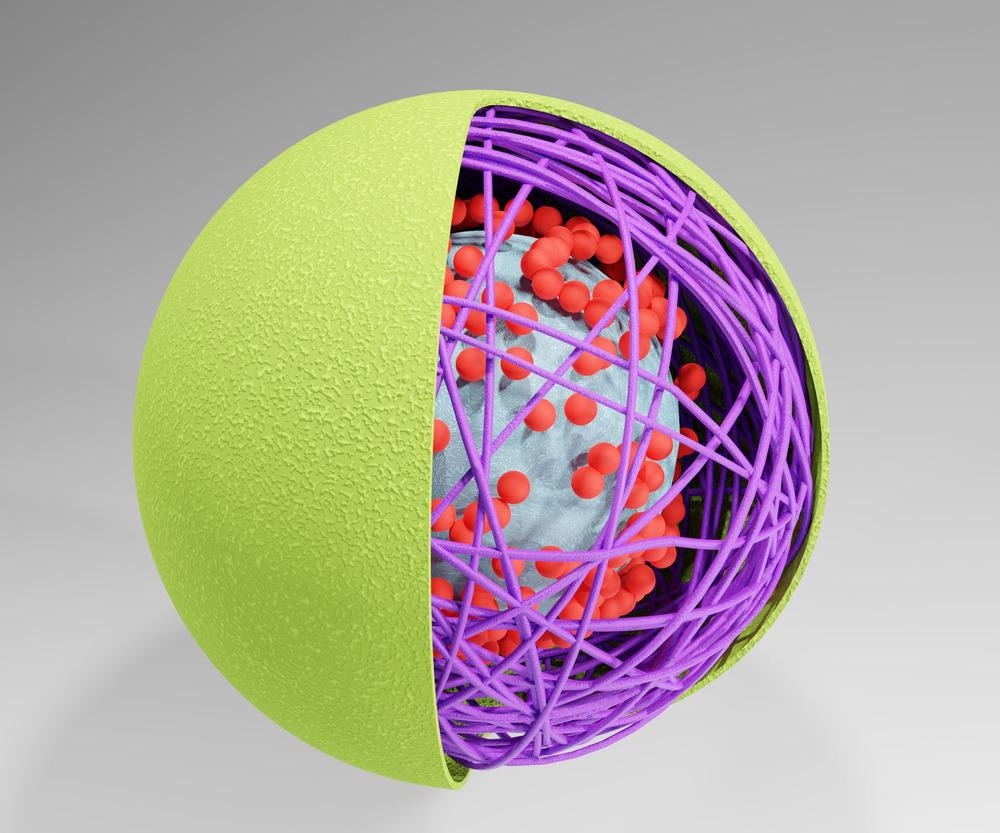

This article looks at the relationship between polymer structures and drug loading, release, degradation, and cellular interactions.

Image Credit: Love Employee/Shutterstock.com

What is Polymer-Based Drug Delivery?

Polymer drug delivery uses a device or a formulation that facilitates the incorporation of a therapeutic substance in the body. Polymers are used extensively for drug delivery owing to their bulk and surface properties. They assist in delivering active pharmaceutical ingredients into the body in a controllable manner. Polymers used for drug delivery should be non-immunogenic, non-toxic, and water-soluble.

Natural polymers such as hyaluronic acid, poly(lactic acid), poly(glycolic acid), polysaccharides, dextrin, and chitosan, and synthetic polymers such as poly(ethylenimine)s, poly(N-isopropyl acrylamide)s, dendritic polymers, and poly(2-hydroxyethyl methacrylate) are commonly used as polymeric drug delivery systems.

Significance of Polymer Structural Properties in Drug Delivery

The structural properties of different polymers considerably influence the cellular interaction of a drug with the polymers, as well as drug degradation, release, and loading. Properties such as crystallinity, water miscibility, melting and glass transition temperatures, hydrophobicity, and hydrophilicity impact the drug release and loading on the polymer microparticles.

Polymer degradation critically influences drug release rates, while cellular interactions such as cell proliferation and cell adhesion can be influenced by hydrophobicity, crystalline size, glass transition temperature, and rigidity of polymers. Certain polymeric nanoparticulate systems can cross the blood-brain barrier and protect against chemical degradation. Smart polymers that respond to external stimuli are highly beneficial for targeted drug delivery. Surface modification of polymers can increase their blood circulation duration.

Role of Polymer Structural Properties in Common Polymer-Based Drug Delivery Systems

In terms of drug delivery, polymer devices can be classified as externally triggered systems, chemically controlled systems, solvent-activated systems, and diffusion-controlled systems.

In a solvent-activated system, drugs are typically loaded into hydrogels or dehydrated hydrophilic polymers by packing both materials together. Solvent-activated systems have extremely low diffusivities and remain below the glass transition temperature in the absence of an aqueous solvent. However, the hydrogels swell and start to absorb water once they are exposed to an aqueous environment.

In chemically non-crosslinked polymers, any dissolution leads to an erosion front. Polymers operating as swelling-controlled systems transition from glassy to the rubbery state during solvent swelling, which dissolves the dispersed drug deposits and relaxes the polymer chains. The mechanism simultaneously creates two moving fronts, swelling and diffusion, in addition to the erosion front.

In biodegradable systems, the erosion of the polymer molecular structure occurs when the chain fragments in crystalline systems dissolve without any chemical interaction. However, the dissolution occurs when the polymer interacts with water through hydrogen bonding mechanisms or charge interactions and absorbs the surrounding aqueous solvent.

Both erosion and degradation can occur as bulk or surface processes. In surface degradation, the polymer matrix is removed progressively without changing the polymer volume fraction, while in bulk degradation, the physical size of the polymer remains unchanged until it is completely eroded or degraded and the remaining volume of the carrier decreases over a certain duration.

Chemically degradable polymers require proteolytically or hydrolytically labile bonds in their crosslinker or backbone. Thus, a large number of biodegradable synthetic polymers depend on the hydrolytic cleavage of ester derivatives such as poly(ε-caprolactone) and poly (lactic/glycolic acid) or ester bonds.

More from AZoM: A Theoretical Framework for the Thermal Welding of Polymers

Additionally, hydrolysis acts on certain other polymers that include poly(cyanoacrylate), poly(phosphazenes), poly(phosphoesters), poly(orthoesters), and poly(anhydrides). Dissolution and degradation processes can accelerate automatically in these polymers as degradation mechanisms release an acid product that either ionizes a hydrophobic structure in order to facilitate greater absorption of water by the polymer matrix or acts as a catalyst for further degradation.

In diffusion-controlled systems, the polymers are monolithic and simple in nature. The drug is initially dissolved in the outer layer of a fully swollen or non-swellable polymer matrix and then moves to the polymer core. The matrix does not degrade during the therapeutic life of the drug. Eventually, the drug particles present in the matrix start to diffuse outside when the matrix is injected into the body.

Smart polymers or environmentally responsive systems are referred to as an extensive range of linear and crosslinked polymer networks that can undergo a substantial chemical or physical change when exposed to an external stimulus. Physical stimuli such as electric and magnetic fields, ultrasound, and temperature can directly control the energy level of the solvent/polymer system and induce a response from the polymer at a certain critical energy level.

Chemical stimuli such as chemical agents, redox potential, and pH generate a response from the polymer by changing the molecular interactions either between solvent and polymer through adjustments in the hydrophilic/hydrophobic balance, or between polymer chains by influencing the electrostatic repulsion, backbone, or crosslink integrity or the proclivity for the hydrophobic association.

The forms of behavioral changes can include changes in conformation, hydrophobic-hydrophilic balance, and solubility. These changes can be observed in several ways, such as the self-assembly of amphiphilic polymers, sol-gel transition of physically crosslinked hydrogels, deswelling/swelling of covalently crosslinked hydrogels, and the coil-globule transition of polymer chains.

Hence, the structural properties of polymers have a substantial influence on the entire polymer-based drug delivery process, which necessitates further studies in this area to gain more insights into the mechanistic and molecular properties of polymers in order to apply the process in a more effective manner.

References and Further Reading

Liechty, W.B., Slaughter, B.V., Peppas, N.A., et al. Polymers for Drug Delivery Systems. Annual Review of Chemical and Biomolecular Engineering 2010. https://doi.org/10.1146/annurev-chembioeng-073009-100847

Sharma, S., Nayak, A., Yadav, T. et al. Polymers in Drug Delivery. Journal of Biosciences and Medicines 2016. https://www.scirp.org/journal/paperinformation.aspx?paperid=62762

Kim, S.W. and Sung, Y.K. Recent advances in polymeric drug delivery systems. Biomaterials Research 2020. https://biomaterialsres.biomedcentral.com/articles/10.1186/s40824-020-00190-7

Miles, Catherine Elizabeth. Understanding how polymer structure–property relationships control drug loading, release, degradation, and cellular interactions. Retrieved from https://rucore.libraries.rutgers.edu/rutgers-lib/66984/

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.