The circular economy model is a proposed solution to the climate catastrophe that has gathered widespread support among legislators and industry leaders alike. The industrial chemical sector supplies materials for 95% of all manufactured products, and it has a key role to play in transitioning away from the unsustainable “take-make-waste” manufacturing model we have today.

Image Credit: General photographer/Shutterstock.com

What is the Circular Economy?

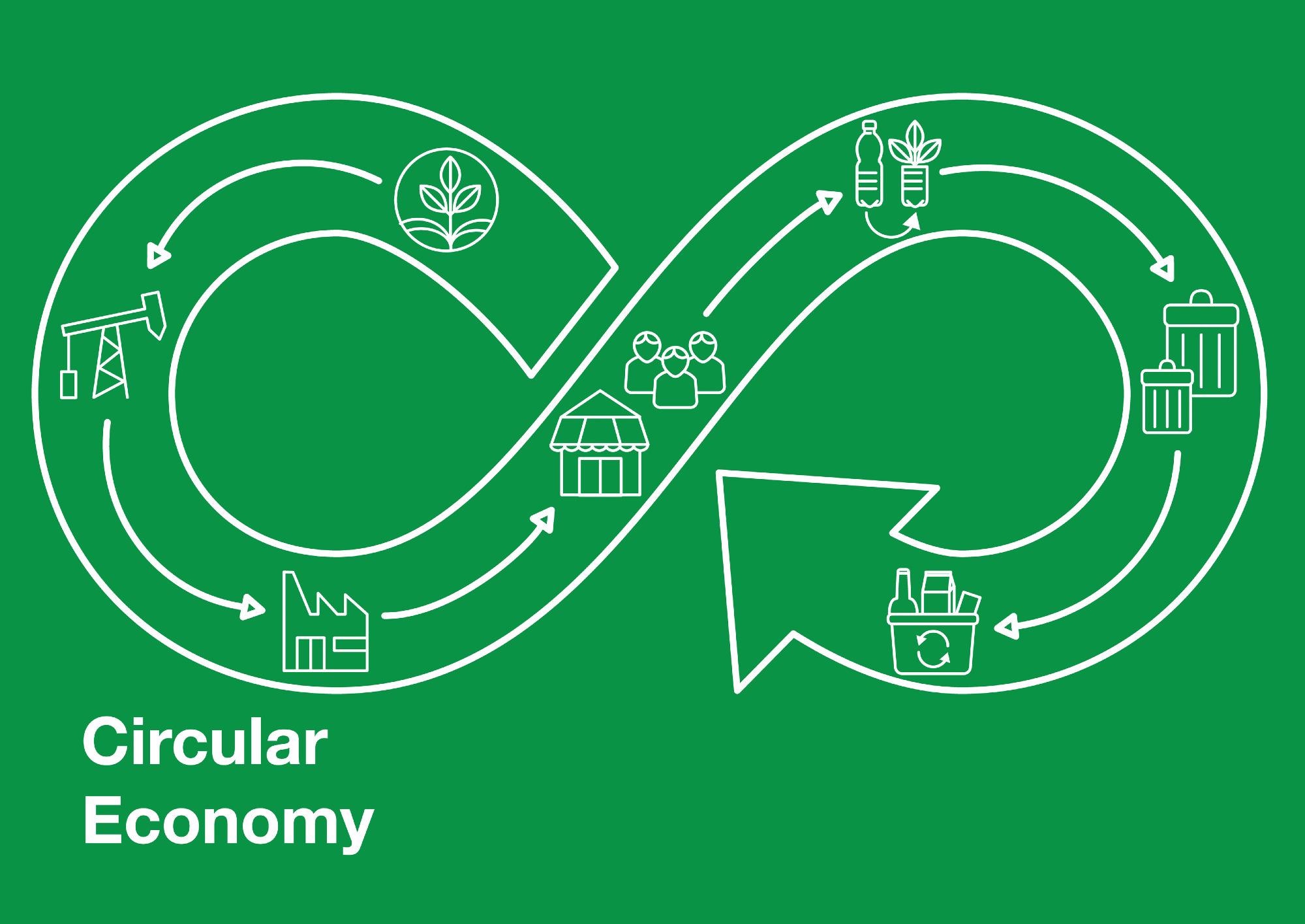

Advocates of the circular economy model describe today’s product system – extracting finite resources, processing them into materials and then products for consumption, distributing the products, consuming them, and throwing them away – as linear. It starts with extraction and ends with disposal, and consumes a lot of energy along the way.

As an alternative to this “take-make-waste” system, government and industry leaders have begun to transition toward a circular economy. This is one in which the “loop” of the linear system – product cycles that only go in one direction – are closed. A closed loop means a material remains in use, does not go to waste, and equivalent new material is unnecessary.

The goal of a circular economy is to reduce or even eliminate our need for new materials. This is done by closing the loop in product cycles by reusing items or recycling their materials when they are at the end of their life, and designing products for multiple uses over a long period of time in the first place.

Closing Loops in the Chemistry Sector

Chemistry sector leaders have responded to the challenge of the circular economy. The sector is using more alternative feedstock such as sequestered carbon and bio-based feedstocks, as well as increasing its use of recycled material.

The sector also contributes to making materials and products more durable, extending their lives, and reducing waste and demand for new products in the process.

The chemical sector also has a role in all forms of recycling (mechanical, chemical, and organic), further involving it in the wider circular economy.

A promising new part for the chemical sector to play in transitioning toward a circular economy lies in the development of new bio-based chemical products that – unlike mineral-based alternatives – are not extracted resources but can be produced sustainably relative to their energy efficiency.

Image Credit: MG_vectors/Shutterstock.com

Using Bacteria to Recycle Carbon Waste for Chemical Products

A team of scientists from Illinois, U.S.’s Northwestern University, and gas fermentation technology developer LanzaTech, recently used a bacteria-based process to recycle waste carbon dioxide into useful industrial chemicals.

Their study, published in the journal Nature Biotechnology in 2022, demonstrated a bacteria strain’s ability to recycle carbon dioxide into acetone and isopropanol (IPA) – two of the most commonly manufactured chemicals. The authors described a process of selecting, engineering, and optimizing the bacteria strain to achieve this novel bacterial carbon conversion capability.

Read Our Interview With The Researchers Here: Converting Carbon to Key Chemicals with Bacteria

Acetone and IPA are typically manufactured with fossil fuels, but this technique obviates the need for them. It also removes greenhouse gasses from the atmosphere with a critical gas fermentation step in the process. As a result of this, the researchers found a potential 160% reduction in greenhouse gas emissions (replacing emissions with carbon-negativity representing 60% of their total weight) through a life-cycle analysis evaluation.

As bulk and platform chemicals, acetone and IPA have a combined global market of over $10 billion. IPA is the base ingredient for one of the two sanitizer formulas recommended by the World Health Organization, which are highly effective at combating Coronavirus. Acetone is a solvent used in the manufacture of numerous plastics, synthetic fibers, polyester resin, cleaning products, and cosmetics.

The researchers used a carbon-negative gas fermentation process to produce Clostridium autoethanogenum, a LanzaTech-engineered anaerobic bacteria strain. Then, they reprogrammed the bacterium with synthetic biology techniques to make it ferment carbon dioxide and produce acetone and IPA as the fermentation products.

The team is confident that these reprogrammed bacteria strains can be produced with the carbon-negative gas fermentation process at industrial scales. This would result in less demand for fossil fuels without relying on reducing demand for sanitizers and solvents, as well as removing manufacturing sources of greenhouse gas emissions. The scientists also believe their approach could be applied to create other useful industrial chemicals sustainably, with bacteria.

Claim your FREE Visitor Badge for ChemUK 2022

References and Further Reading

Brudermüller, M. (2020). How will the chemical industry contribute to the circular economy? Politico.eu. [Online] Available at: https://www.politico.eu/sponsored-content/how-will-the-chemical-industry-contribute-to-the-circular-economy/.

Liew, F.E., R. Nogle, T. Abdalla, et al. (2022). Carbon-negative production of acetone and isopropanol by gas fermentation at industrial pilot scale. Nature Biotechnology. Available at: https://doi.org/10.1038/s41587-021-01195-w.

Northwestern University (2022). Bacteria upcycle carbon waste into valuable chemicals. Eurekalert. [Online] Available at: https://www.eurekalert.org/news-releases/943910.

Pilkington, B. (2022). The Circular Economy and Electronics. AZO Materials. [Online] Available at: https://www.azom.com/article.aspx?ArticleID=21336.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.