Cultivated meat, also known as cultured meat, is real animal meat made in a laboratory utilizing tissue engineering techniques to grow animal cells in vitro. This form of food production eliminates the need to raise and farm animals.

Cellular agriculture, a branch of the food industry with the potential to solve animal welfare, food insecurity, human health, and the significant worldwide environmental concerns caused by meat production, is expected to account for 35 percent of global meat consumption by 2040. Fermentation is being reinvented, pushing the boundaries of biology by developing new food opportunities that will be more precise, healthy, sustainable and humane.

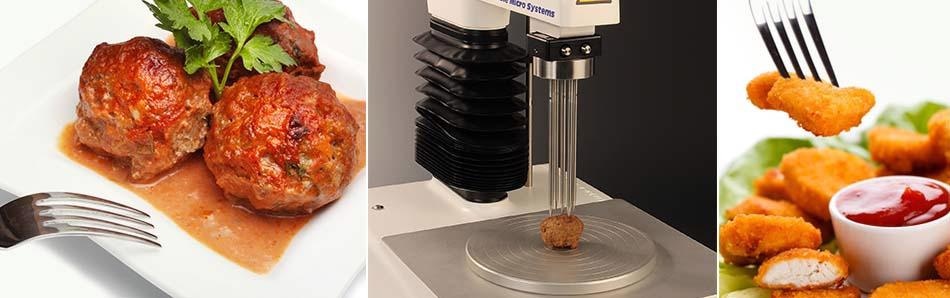

Image Credit: Stable Micro Systems Ltd

The texture of meat or fish has traditionally been the most significant aspect in determining consumer approval, and cell produced substitutes are no exception. It's critical for a consumer branching out to try a new, unfamiliar protein source to like the texture, especially since the sensory experience must be 'same-as'. Consumers are quick to express their displeasure if the taste, texture, or cooking properties of a traditionally farmed meat or fish alternative fall short of the real thing, and while they may be willing to try cultured or fermented products that do not involve animal cruelty, they will not be willing to sacrifice taste and texture.

How to Assess/Compare a Cultured Meat Product Texture with the Real Version

As with all alternative products, the proof is in the testing. The product will be rejected if the texture (and flavour) is not true to consumer expectation. That’s where texture analysis comes in. Once the alternative product is created it will need to be compared with the ‘real thing’, who’s texture analysis fingerprint will have been determined as the ideal textural quality. If the replacement product is in any way different to the traditional product’s texture it may well be back to the drawing board.

Stable Micro Systems manufactures instruments that measure the tensile and compressional properties of raw ingredients, individual materials and finished products. As with any food innovation, a large amount of research takes place during development, but the end-product must also go through a quality control process to assess its mechanical (and sensorial) properties. A Texture Analyser is a crucial part of this procedure, giving a reliable way to test products by applying a choice of compression, tension, extrusion, adhesion, bending or cutting tests to measure their physical or textural properties e.g. firmness, toughness, chewiness and bite force, to name but a few.

Image Credit: Stable Micro Systems Ltd

A range of Texture Analysers are available varying in maximum force capacity and height options suited to the requirements of the application.

A vast range of probes and fixtures can be attached to the instruments depending upon the product/material to be tested. Whether you need a knife blade to measure the bite force or your meat/fish, a Kramer Shear cell to assess chicken fillet toughness, a ball probe to assess flesh firmness or a multiple puncture probe to compare chicken nugget tenderness – texture analysis is the tool to employ.

Image Credit: Stable Micro Systems Ltd

Different ways to measure bite force of burgers, toughness of chicken pieces, firmness of flesh, or tenderness of chicken nuggets

An Example of How Cultured Meat/Fish Texture Can be Tested – Cutting Test

Consider the front teeth in a line – their action can be imitated by the use of a blade on the Texture Analyser. If the first assessment of meat texture characteristics by a consumer is to cut or bite through the fibres, a logical test approach would be to measure the force to cut or break the fibres to provide an indication of what the consumer might perceive.

Cutting measurements are frequently used for the measurement of meat samples. They enable the researcher to measure the hardness and toughness of a sample in a quick and clean measurement. The biting action is used as a basis of many devices designed to provide a measure that will closely relate to human assessment.

The ‘bite force’ property can be assessed with a Standard Knife blade. However, empirical methods of assessing texture are often challenged by a lack of homogeneity or uniformity in samples. Sometimes the sample to be analysed may be of variable configuration or structure from piece to piece. This challenge calls for a set of tests that deal with the compromise of sample heterogeneity in order to improve the chance of obtaining a repeatable result.

By testing a larger number of pieces, or a wider surface area with more testing surfaces an averaging effect is thereby created which is the result of a representative set of pieces or surfaces. A Kramer Shear Cell is one such example where the maximum force to shear a chosen number/weight of pieces and area under the curve is (usually termed the ‘work of shear’) are recorded and taken as an indication of bulk firmness – a larger value indicating a firmer sample.

Typical cutting test on a Texture Analyser imitating a biting or cutting action. Image Credit: Stable Micro Systems Ltd

An Example of How Cultured Meat/Fish Texture Can be Tested – Penetration Test

A penetration test could well be considered the most simple of all tests for the assessment of firmness. As the size of the probe surface area is constant this often means that the sample size does not need to be carefully controlled.

Typical multiple penetration test on the Texture Analyser mimicking real-life food interaction. Image Credit: Stable Micro Systems Ltd

Despite the simplicity of penetration tests, when faced with a non-homogeneous product (which is common for meat products) penetration is highly compromised as a smaller surface area for measurement is also more sensitive to variations in sample structure and low reproducibility, and misleading data is obtained. Results may show a wide variance between maximum and minimum forces depending on whether the probe meets with, for example, internal structure variation such as is usually present in meat products.

The use of a Multiple Puncture Probe that penetrates the sample in several regions serves to create an averaging effect and is therefore usually more repeatable. Using several testing pins, attached to the Texture Analyser, manufacturers can test non-uniform products containing particulates of different sizes, shapes, structures, and levels of hardness, to provide repeatable results.

The Future of Food with Cell Cultured Foods

Traditional farming and agriculture methods are clearly not going away any time soon. In fact, if they did, the world would be in a whole lot of trouble. However, as the population continues to grow, and more emphasis is put on environmental sustainability, cell agriculture can help to fill that void. The pandemic also exposed the instability of worldwide supply chains, motivating countries to push for the production of their own food. The future of cell cultured foods looks bright, particularly in places where intensive farming is not possible. It will be an interesting market to watch over the next few years and quality control methods will need to be introduced for consumer acceptance. It’s only a matter of time before the legislation catches up with this technology to produce these products and it’s a race to get the best product in place at the start line!

Discover the typical types of tests used in the meat and fish industry for texture measurement

See how Meat & Fish Industry Leaders use Texture Analysis to get ahead of their competition

This information has been sourced, reviewed and adapted from materials provided by Stable Micro Systems Ltd.

For more information on this source, please visit Stable Micro Systems Ltd.