New, creative, innovative, incredible materials need new testing approaches to measure their novel mechanical properties. These physical properties can be useful or a drawback. But if you can measure them then you can control them.

Image Credit: Image Credit: Stable Micro Systems Ltd

A Texture Analyser is frequently relied upon for use in innovative fields of industry, such as the invention and development of novel materials, due to the empirical or imitative way in which it can be utilised. The Texture Analyser offers method creation flexibility not seen in other materials testing devices because it is not constrained by fundamental or standard methodologies and analysis possibilities. As a result of its universal application in all industries, it appears in a wave of recent patent applications where testing solutions for the measurement of properties of novel materials taking unusual sample forms are needed for mechanical testing challenges that can't be solved using rigid, old-school standard technique approaches.

How Texture Analysis Can Measure Novel or Innovative Product Mechanical Properties

Stable Micro Systems manufactures Texture Analysers/Materials Testers to test the mechanical properties of all types of products or materials by applying a choice of compression, tension, extrusion, adhesion, bending or cutting tests to measure a product’s mechanical properties e.g. tensile strength, puncture strength, peel force and compressibility, to name but a few.

A range of Texture Analysers/Material Testers varying in maximum force capacity. Image Credit: Image Credit: Stable Micro Systems Ltd

New products that take new forms and have innovative properties require new testing solutions to ensure that the purpose for which they are designed is met and their structural or mechanical requirements match their intended location of use.

Nothing is more exciting that the potential to create shape morphing aircraft skins, self-healing materials for space missions, or tactile electronic skin. Or how about an unmanned vehicle whose flexible body is designed to mimic tilt sensing inspired from the way jellyfish move or the creation of aqueous fragrance release gel formulations with considerable strength, elasticity and mouldability. These novel developments need testing so that their properties can be quantified for comparison with any future redesign, modification or as a quality control benchmark when going into production.

Innovative Materials Where Standard Methods Do Not Apply

The future of technology lies in the creation of new materials that offer either the same properties as existing products but provide benefits such as biodegradability or different properties and thereby allow new applications in such areas as medicine, electronics or building materials, for example. Materials scientists need tools such as a Texture Analyser that offer a creative approach to physical property measurement so that each step of the material creation process can be quantified and compared.

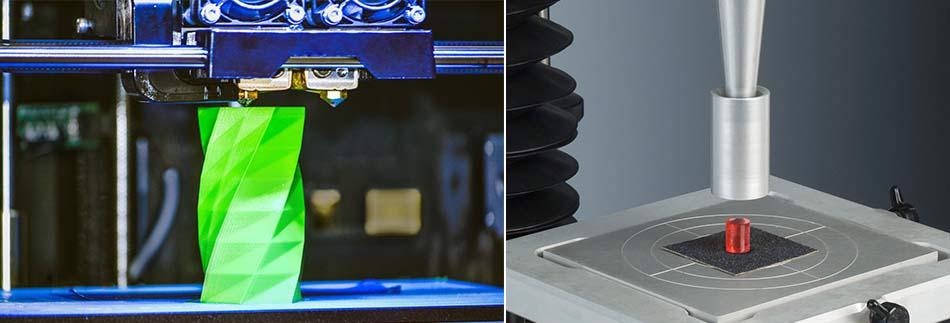

3D Printed Materials

In the recent decade, dozens of new novel materials have emerged to support new technologies like 3D printing. Texture Analysis/Materials Testing is at the forefront of this technology since any 3D printed item, whether it is a produced food product or a medical component, must have structural integrity in order to be suitable for purpose. Mechanical characteristics are crucial in assessing if a printed material can sustain the forces that must be applied to it without deforming in the way that is desired.

Mesh implants, veterinary dosage forms and microneedles are all examples of products that can now be printed but for which a standard method does not exist and thereby requires the flexibility of use of a Texture Analyser to find a mechanical testing solution that suits the novel form that the product takes and the properties that are required to be tested.

Measuring the compressive strength of 3D printed parts. Image Credit: Image Credit: Stable Micro Systems Ltd

Development of Innovative Packaging and Biodegradable Materials

Simultaneously, the packaging industry has moved swiftly to develop biodegradable (e.g. drinking straws) and edible utensils (e.g. cutlery), as well as utilising food industry by-products. However, because these novel packaging solutions are expected to have the same attributes as traditional packaging materials, materials testing/Texture Analyser tools are an important tool in the quest for packaging perfection.

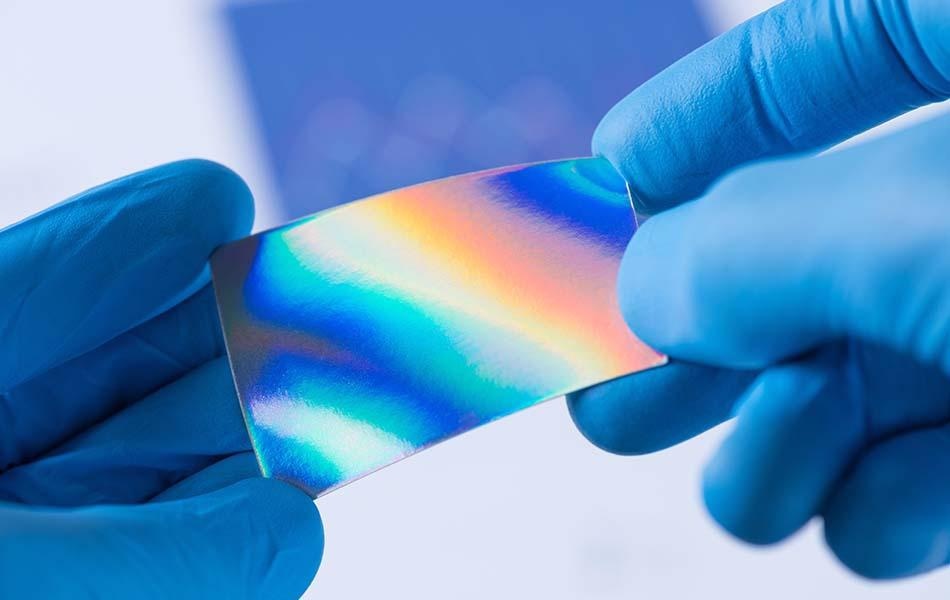

Different ways to test packaging films. Image Credit: Image Credit: Stable Micro Systems Ltd

Testing of Electronic Product Physical Characteristics

In the fast-paced world of electronics the constant redevelopment of mobile phone technology calls for the assessment of materials with properties that provide new functional opportunities and experiences for the consumer. With recent development of display-relating technologies, display devices transformable at the stage of use such as folding, rolling in a roll shape or stretching like a rubber band have been researched and developed. These displays may be transformed into various shapes, and therefore, may satisfy demands for both a larger display at the stage of use and a smaller display for portability. However, existing adhesive compositions for a foldable display have had problems in that, even when satisfying such a folding reliability condition, delamination and panel breakage occur when conducting a dynamic folding test at −20° C, a severe condition among conditions allowing an actual folding test. A patent has recently been released by LG that provides satisfying reliability conditions without causing problems such as delamination and breakage even at −20° C when conducting a folding test while maintaining properties of existing adhesive compositions for a foldable display such as reliability conditions and adhesion properties at room temperature and high temperature. They used their TA.XTplus Texture Analyser to perform peel tests.

Examples of work in the electronics field where the Texture Analyser has been employed include:

- Measurement of the peel strength of printed circuit board track

- The force required to pull components from a printed circuit board

- Strength of crimp joints

- The push button and membrane micro-switch where the measurement of the change of resistance during depression is measured

- The characterisation of a conductive gasket as it is compressed, measuring the force required to reduce its electrical resistance to form an effective RF seal

Measuring the actuation force of keyboards. Image Credit: Image Credit: Stable Micro Systems Ltd

There are some other unusual ways to mimic and test things that occur in everyday life. Here are a few examples of novel physical testing methods that use the Texture Analyser to imitate an action that a consumer typically performs in their use of a product in order to objectively measure and quantify mechanical properties.

How to Measure the Combability Properties of Hair:

An imitative test is used industry-wide for measuring the force required to run a comb through a treated hair sample, in the form of a ‘hair combing test’ on a Texture Analyser, assisting manufacturers in the development of more effective conditioning agents. The Hair Combing Rig allows manufacturers of shampoos, conditioners and smoothing agents to evaluate the ‘combability’ of treated hair samples to substantiate claims of ‘improved manageability’.

This rig involves a tress sample clamped at the top and allowed to hang freely from a stand. A comb attachment is fixed to the load cell and is pulled down through the hair sample, allowing frictional forces to be measured. The assembly is positioned on the Texture Analyser and the supported length of hair is held vertically, near to the comb. When instructed, the arm of the Texture Analyser brings the comb down through the hair, recording the necessary force as it moves. At the end of a stroke, the comb is mechanically disengaged and moves back to its starting position to begin the next combing cycle. This allows multiple combing strokes without disturbing the hair on the upward movement in order to replicate consumer action.

Measuring the combability of hair. Image Credit: Image Credit: Stable Micro Systems Ltd

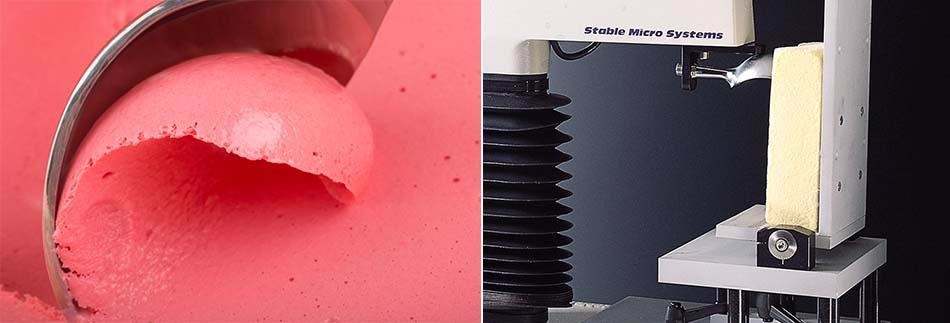

How to Measure the Scoopability Properties of Ice Cream:

To imitate the action of pushing a scoop of ice cream into a cone we developed the method shown below and to measure the ice cream’s scoopability we have the Ice Cream Scoop Rig. Sometimes you just need to keep the measurement simple and attempt to recreate the action that is performed in real life when a consumer makes a subjective assessment.

Measuring the force to scoop ice cream. Image Credit: Image Credit: Stable Micro Systems Ltd

For a full summary of typical texture analysis tests that can be performed on innovative materials and products:

Other Physical Test Types using a Texture Analyser

Video Credit: Stable Micro Systems Ltd.

This information has been sourced, reviewed and adapted from materials provided by Stable Micro Systems Ltd.

For more information on this source, please visit Stable Micro Systems Ltd.