Plastic pollution and climate change have increased the pressure on companies and governments to cut down their CO2 emissions and look for alternatives to present single-use plastic packaging. To minimize the effect of packaging on the carbon footprint of food products and increase the upcycling potential, the industry needs to introduce a range of new materials.

Image Credit: Stable Micro Systems Ltd

Agricultural production and agro-industrial processing generate a large amount of waste and by-products, much of which is derived from fruit, vegetable or fish waste, for example. Agri-food by-products and waste generation are having an impact on environmental, economic, and social sectors. To the environment, these contribute to Green House Gas (GHG) emissions. Many of these biomaterials are not utilised and end up in municipal landfills where they create serious environmental problems due to microbial decomposition and leachate production. In some cases, the by-products are burned to remove fungi and parasites. From an economic point of view, the adverse impact is due to the costs related to the handling of solid waste in landfills.

We need to reduce the dependency on non-degradable petroleum-based plastics by substituting with other materials and there is an increasing need for biodegradable, environmentally friendly and functional food-packaging materials. In this regard, proteins obtained from agri-food industry by-products may become a promising and sustainable source of such materials.

The Problem of Waste and the Upcycling Solution

Making packaging more sustainable entails involving all stages of the supply chain in order to bridge the gap between manufacturers and recyclers and assist businesses in better understanding packaging circularity and future-proof design. Eco friendly alternatives to single use plastics using waste food are being sought after by packaging manufacturers and researchers are racing to develop innovative packaging to incorporate upcycled materials. These innovations include packaging made from mycelium (the vegetative root structure of a mushroom), rice husk, brewers’ spent grain, grasspaper boxes and papers containing sun dried grass (the production of grasspaper uses up to 80% less energy than that of wood pulp, with dramatically reduced water requirements).

The Potential Problems with Upcycled Packaging

Today's manufacturers understand the importance of packaging to their success. If a product's packaging fails, it may become unfit for function, impossible to handle and store, or even utterly unusable and unsellable, regardless of how desirable or valuable the product is. Poor packing can harm not only the goods within, but also the reputation and profitability of the company that provided it. Texture analysis is crucial for ensuring that requirements are met in areas like material mechanical property measurement.

How Texture Analysis Can Measure Packaging Physical Properties

Stable Micro Systems manufactures Texture Analysers/Materials Testers to test the mechanical properties of all types of products or materials by applying a choice of compression, tension, extrusion, adhesion, bending or cutting tests to measure a product’s mechanical properties e.g. tensile strength, puncture strength, peel force and compressibility, to name but a few.

A range of Texture Analysers/Material Testers varying in maximum force capacity. Image Credit: Stable Micro Systems Ltd

Materials testing for potential packaging materials and finished packs is equally as vital as product evaluations. Assessing and comparing different materials allows manufacturers to select packaging materials that are resilient enough to withstand the rigours of handling and distribution but at the same time allow users simple access to the product inside.

From assessing newly developed substrates and adhesives to completed packs or films that are ready for shipping and sale, there is now a wide selection of testing equipment and methodologies that may help producers choose which package developments best fulfil their unique demands. All of the tests listed here can be carried out with the TA.XTplus Texture Analyser or the TA.HDplus Texture Analyser with a variety of rigs and accessories.

How to Measure the Compressive Properties of Packaging Boxes:

Uniaxial compression testing allows manufacturers and retailers to evaluate the crush resistance of any newly developed packaging container, determining how resistant they are to deformation when an even force is applied across a surface. If the contents of a pack are fragile and/or precious, this is critical.

A Compression Plate is used in the test, which travels downwards at a constant speed while applying a specified strain to the sample directly below it. The force required to distort the sample container is measured, revealing how well the pack will withstand storage, transportation, and handling.

Image Credit: Stable Micro Systems Ltd

How to Measure Tensile Strength and Elongation of Films:

The use of biopolymers as packaging material has become increasingly popular over the last few decades in the need to shift towards a greener alternative. Although natural biopolymers could be attractive alternatives to conventional plastic, films made from biomaterials potentially have lower mechanical strength and poorer barrier properties – compromising functional properties on the safety of the product being packaged. These properties can be improved by the addition of certain materials but you'll need to assess their effect on mechanical integrity for packaging product success.

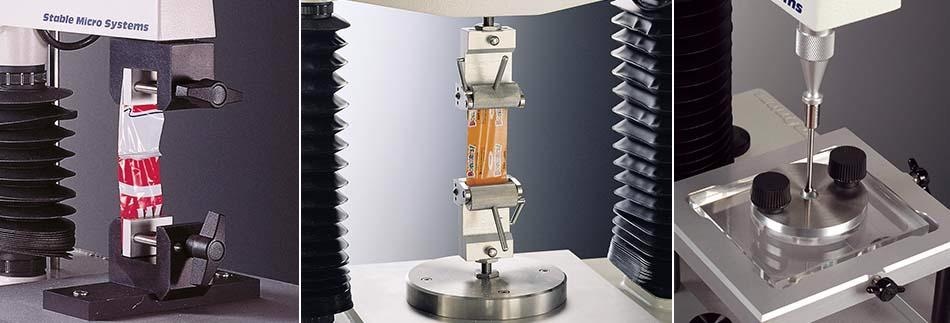

Tensile grips, self-tightening roller grips and film extensibility rig providing film tension testing. Image Credit: Stable Micro Systems Ltd

Grips can be used to test tensile strength and tear properties. Self-tightening roller grips work well with thin samples with a flat surface or materials that change properties as tensile force is applied. Self-tightening crosshatched rollers hold the sample at each end and apply the pulling force to identify the rupture point. Tensile grips, on the other hand, are perfect for evaluating the mechanical qualities of heavy-duty packaging materials. The tool measures the greatest force required to stretch the sample to breaking point using a simple pulling movement. In this case, standard methods such as ASTM D882-02 can be applied. Tensile grips, when employed in a cycling motion, test the substrate material's flexibility. A film extensibility rig can also be used for biaxial extension tests by supporting a film sample around a hole and penetrating using a spherical probe.

Examples of How Texture Analysers have been Applied in this Way in Published Research:

How to Measure the Peeling Properties of Packaging Films:

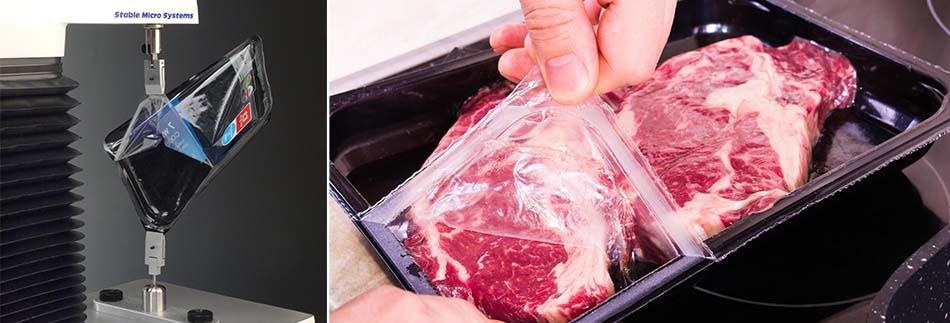

Peel lids and covers are one of the most used packaging methods in medical devices and FMCG products, particularly in the personal care and food industries. In addition to testing the properties of the lid's material when it's in sheet shape, it's also crucial to look into its adhesion to the pack. The performance of the seal between the lid and the pack is important not only for product quality and safety, but also for user-friendliness. The adhesive connections must be strong enough to resist handling, transportation, and storage without breaking or rupturing, while yet being easy to peel back when needed.

Image Credit: Stable Micro Systems Ltd

The Peel strength test rig provides a popular method of testing. The container is held in place by a carrier plate attached to the instrument's base. A pulley and captive wire are carefully positioned underneath the instrument's loadcell on this carrier plate. The loadcell is linked to one end of the wire, and the pull-tab on the lid is connected to the other.

Image Credit: Stable Micro Systems Ltd

The Universal peel rig has a multi-position platform that can hold containers flat or at 45° and 90° angles. Manufacturers can better imitate the actions of consumers, or users, in order to analyse the ease of use and the stability of package seals.

It is clear that accurate, repeatable materials testing is as important in evaluating new packaging options as it is in perfecting the product itself. Using one instrument, manufacturers can safeguard quality standards and ensure consistent performance during production processes, transport, storage and end use. Optimising packaging improves product safety, functionality and aesthetics and customer satisfaction. And in today’s competitive packaging development markets, every one of these factors counts.

For a full summary of typical texture analysis tests that can be performed on materials such as packaging:

Materials & Packaging Physical Characterisation

Video Credit: Stable Micro Systems Ltd

This information has been sourced, reviewed and adapted from materials provided by Stable Micro Systems Ltd.

For more information on this source, please visit Stable Micro Systems Ltd.