For high resolution imaging in a SEM, and for accurate analysis by EDS or EBSD, proper sample preparation is critical. If a sample is cut with scissors or a knife, sections of the sample can compress, resulting in deformation of the original shape.

If a sample is cut after it is frozen with liquid nitrogen, it can be difficult to get a clean section. If mechanical polishing is used, problems of physical deformation of the surface, fine scratches, and contamination can occur. And for composite materials with thin and soft layers, accurate thickness measurements can be difficult as the layers tend to be crushed.

Figure 1. Coxem CP-8000+ Ion Mill. Image Credit: COXEM Co. Ltd.

To simplify preparation of these difficult samples, Coxem has developed the CP-8000+ Ion Mill. An Ion milling system is a sample preparation apparatus that can section a surface very cleanly by applying an argon plasma ion beam to the sample. Because an ion mill removes material on an atomic level, sections prepared via ion milling are much cleaner and more precise than can be obtained using traditional polishing methods. No mechanical stresses are imposed upon the sample, and contamination is eliminated because no chemical polishing agents are used. In addition, ion milling systems can etch an area about 50 times as wide as a FIB using a gallium ion beam in the same amount of time, providing faster sample turnaround time at significantly lower cost.

When equipped with the appropriate sample holder, an Ion mill can be used in a broad range of applications, including fibers, ceramics, metals, polymers, films, and even powders. The CP-8000+ manufactured by COXEM is an ion milling system that provides an etching rate of over 700 um per hour (at 8 kV, Si wafer), and can be quickly mastered by even novice users. Equipped with a unique one-touch smart sample holder, sample loading is fast and precise, and the etching progress can be observed in real time via a camera built into the chamber. The CP-8000+ even includes a special sample holder for flat milling, so no additional options or accessories are required for wide area milling.

The examples below show just a few of the types of samples that can be cross sectioned and prepared using an ion mill. If your work requires extensive preparation of difficult samples, an ion mill may be the ideal solution to help speed up sample prep and improve your imaging and analysis.

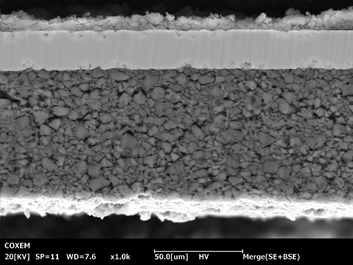

Figure 2. Anodic Powder on Al Foil. Image Credit: COXEM Co. Ltd.

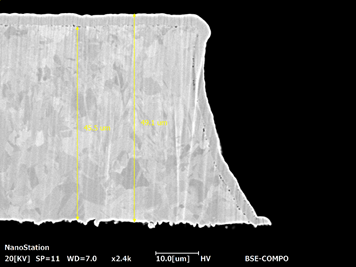

Figure 3. Electrode. Image Credit: COXEM Co. Ltd.

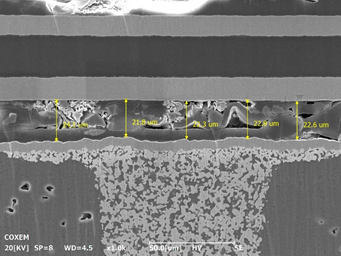

Figure 4. Printed Circuit Board. Image Credit: COXEM Co. Ltd.

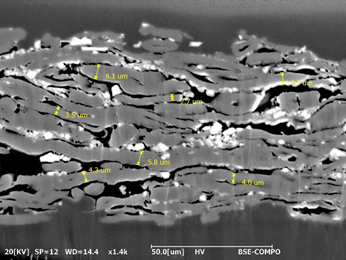

Figure 5. Fiber Film. Image Credit: COXEM Co. Ltd.

Figure 6. Sensor Chip. Image Credit: COXEM Co. Ltd.

This information has been sourced, reviewed and adapted from materials provided by COXEM Co. Ltd.

For more information on this source, please visit COXEM Co. Ltd.