Inductively coupled plasma (ICP) mass spectrometry leverages the power of inductively coupled plasma to ionize a sample. This atomizes the sample, forming atomic and small polyatomic ions which can be detected using specialized instruments.

ICP standards are widely used in ICP-OES. This trace-level, elemental analysis method allows for the investigation of a sample’s emission spectra to identify and quantify any elements present.

Elements can be recognized via their characteristic emission lines and quantified by these lines’ intensity. Trace analysis is typically regarded as a low enough analyte concentration to cause challenges, for example, due to sample size, matrix or washout issues.

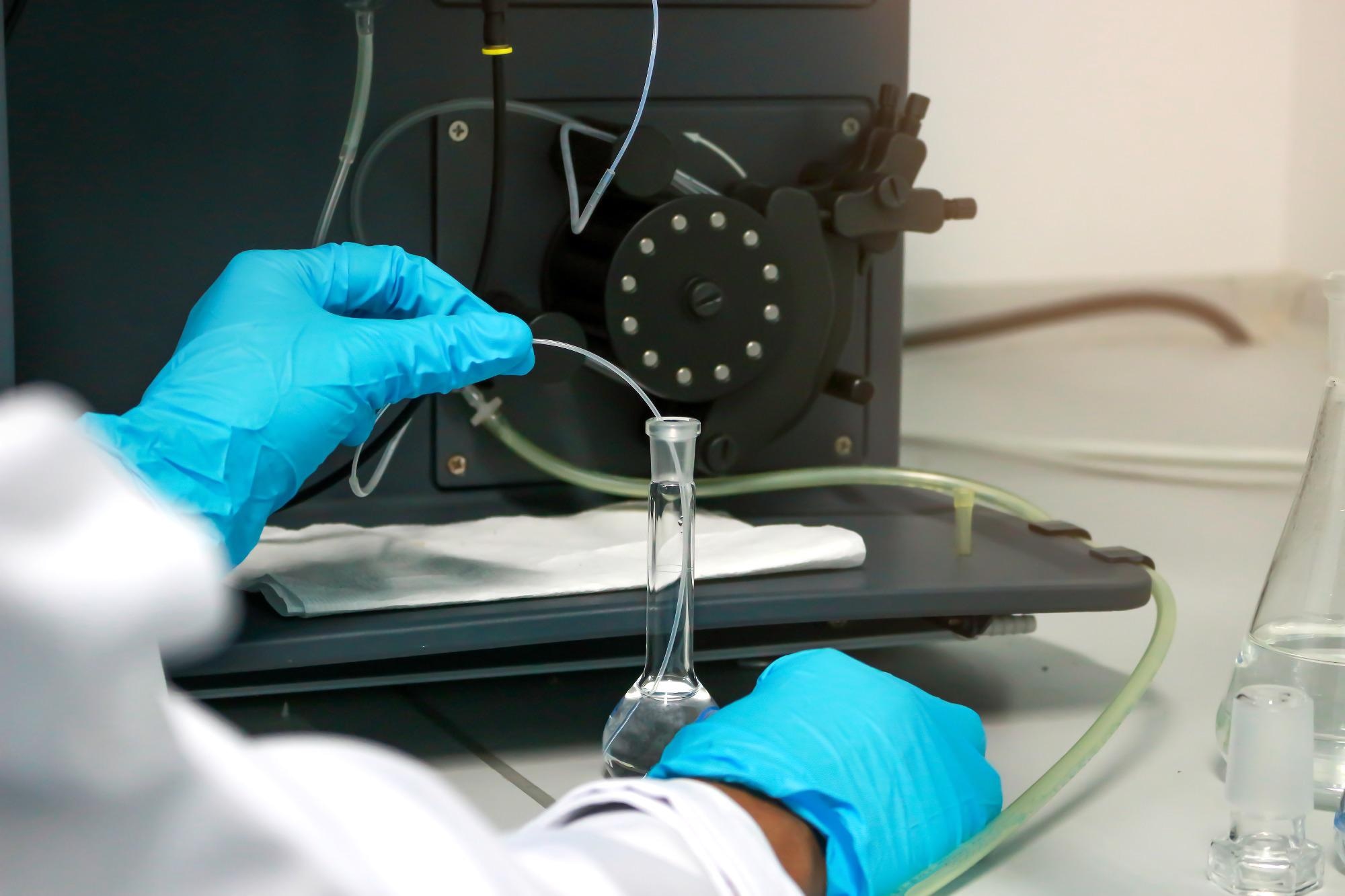

Image Credit: Stella_E/Shutterstock.com

Addressing Washout Issues

‘Washout’ can be understood as the removal of sample solution from the sample introduction system during the analysis process. The previous sample must be entirely removed before introducing the next sample for analysis if carryover contamination from one sample to the next is to be eliminated.

This is important because carryover contamination can lead to incorrect results by introducing interferences or artificially adding elements of interest.

Some solutions include elements that require hydrofluoric acid (HF) to maintain stability.

This can cause an issue in ICP sample introduction systems made from borosilicate glass, where the introduction of samples containing HF will trigger the leaching of boron and silicon from the glass sample introduction system parts into the sample solution.

ICP analysts may opt to employ an HF resistant system such as PFA and PFTE, but there remains a risk that certain elements will leach out of any coatings used in the plastic sample introduction parts.

There will be an increase in carryover from HF-resistant sample introduction system parts as HF concentration increases.

When addressing ICP standard washout issues, it is vital to ensure that all sections and components of the sample introduction system are clean.

Some elements present a greater removal challenge to standard cleaning processes. It may be necessary to soak these parts in a cleaning solution or replace them more frequently where required. PVC peristaltic pump tubing is one example of a part than can be easy to overlook.

It is also necessary to perform an appropriate rinse protocol to avoid washout issues. Determining the most effective protocol may require experimentation, particularly in terms of the optimum time spent rinsing the equipment and the ideal rinse solution.

Diluted acid or water may be adequate in ensuring the elimination of carryover contamination for relatively straightforward sample analysis, but some instrument methods, analytes or concentrations of interest may require the use of more advanced rinse solutions.

ICP Standards from Inorganic Ventures

As a leader in its field, Inorganic Ventures creates custom solutions designed to cater to each experiment’s needs. Higher concentration ranges are provided for user dilution, meaning that no unnecessary elements are added to solutions and help to minimize carryover contamination.

Inorganic Ventures’ ICP standards can help save users’ time and enhance stability. Everything in the company’s custom standards is designed to be appropriate to the methods being used, and the company can make recommendations around matrix and elemental compatibility where required.

With a wealth of experience in wet chemistry and advanced fractionation, Inorganic Standards’ portfolio of certified reference materials (CRMs) has been developed for use in applications ranging from ICP-MS, ICP and IC to atomic absorption wet chemistry and QC.

All the company’s products are stable, compatible, NIST-traceable and designed and tested under ISO 17025 and ISO 17034 guidelines.

This information has been sourced, reviewed and adapted from materials provided by Inorganic Ventures, Inc.

For more information on this source, please visit Inorganic Ventures, Inc.