This article focuses on profile roughness parameters and their significance in characterizing the surface morphology of machined materials.

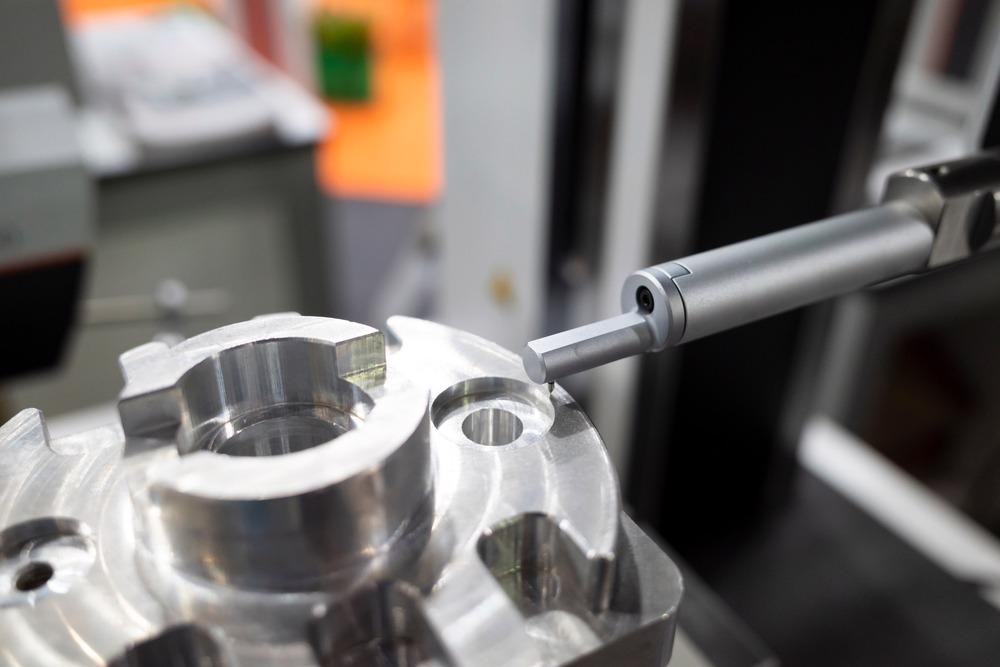

Image Credit: Aumm graphixphoto/Shutterstock.com

What is Surface Roughness?

Surface roughness is referred to as a series of microscopic geometric features of tiny valleys and peaks of different spacings and heights that are typically arranged in a non-deterministic way on a machined surface. Surface roughness critically influences the service life and performance of machined parts as these microscopic features impact the corrosion resistance, contact stiffness, fatigue strength, wear resistance, and sealing of the surfaces. Surface roughness can be classified as either areal or profile. The profile surface roughness can be obtained by intersecting the actual surface with a specified plane.

Surface Profile Filtering

The machined surface often consists of surface components of several spatial frequencies. Among these frequencies, filtering out the long-wave components present in the measured surface data is necessary for evaluating the microscopic surface topography using the surface roughness parameters. International standards classify filters as areal filters and profile filters. The profile filter can split the surface profile into short-wave and long-wave components.

The lateral scale-based two-dimensional (2D) surface topography can be divided into the primary profile (P), roughness (R), and waviness (W) components. λf, λc, and λs profile filters are used to divide these components. λf and λc profile filters define the intersection between the longer wave and W components and the intersection between the W and R components, respectively

λs filter defines the intersection between the shorter wave and R components on the surface. Several types of profile filters can be utilized to determine the cut-off wavelength of short or long waves. For instance, short wave filtering can remove components that are shorter than the R wavelength, while long wave filtering can eliminate the effect of W on the R measurement in the real surface profile.

Profile Roughness Parameters and their Applications

Surface roughness parameters are referred to as the means of communication and tolerance specifications for engineering manufacturing and design. Profile parameters are designated depending on the profile type, such as P, R, or W, that is used to calculate the parameters. For instance, a profile roughness parameter has the R as a prefix.

Typically, profile roughness parameters have four major types of parameters, including hybrid, spacing, amplitude, curves, and related parameters. These parameters are measured on the profile that is perpendicular to the most prominent surface texture direction.

Profile amplitude parameters are referred to as the class of standard parameters that define the vertical characteristics of the surface profile. For instance, parameters such as Rp, Rv, Rz, and Rt define the maximum peak height, maximum valley depth, maximum height, and total height of the profile, respectively. Additionally, parameters Ra, Rq, Rsk, and Rku define the arithmetical mean deviation, root mean square deviation, skewness, and kurtosis of the evaluated profile, respectively.

Profile spacing parameters define the degree of peak and valley density on the surface profile under evaluation by calculating the mean width of the profile elements, while the profile hybrid parameters represent the root mean square value of the ordinate slope in the sampling length.

Curves and related parameters include parameters such as Rmr(c), R∆c, Rmr, Rk, Rpk, and Rvk that describe the material ratio of the profile, profile section height difference, relative material ratio, core roughness depth, reduced peak height, and reduced valley depths, respectively.

The calculation of these parameters is based on either evaluation or sampling length. The evaluation length is the total length in the X-axis used for the assessment of the evaluated profile, while the sampling length is the length in the X-axis direction used for detecting the irregularities that characterize the evaluated profile. W and R profiles are typically evaluated over successive sampling lengths to obtain the sum that represents the evaluation length.

Profile roughness evaluation parameters are used extensively in manufacturing processes. For instance, amplitude parameters are used for adhesion analysis of surfaces, identifying defects in precision-machined surfaces, detecting cracks on the surface, safety analysis of the slide bearing oil lubrication film, monitoring the surface wear of a machined part, and electrical contact effectiveness analysis.

Similarly, spacing parameters are used for deciding the correct filter and coating, detecting fluid flow and punch forming, and tool-condition monitoring, while hybrid parameters are used to identify the adhesion, noise, wear, elasticity, reflectivity, and friction of the surface. Curves and related parameters are used to simulate and predict the wear process and perform the functional evaluation of surfaces with high stress, such as surfaces with stratified functional properties.

Taken together, profile roughness parameters can help in effectively understanding the surface morphology of machined surfaces. These parameters are expected to be used extensively in the manufacturing sector for surface quality evaluation as the current international standards of 2D characterization and measurement are relatively complete.

More from AZoM: How are Micrometers Used to Measure Surface Metrology?

References and Further Reading

He, Baofeng., Ding, Siyuan., Shi, Zhaoyao. A comparison between profile and areal surface roughness parameters. Metrology and Measurement Systems. 2021. 28(3), 413-438. https://doi.org/10.24425/mms.2021.137133

Surface Roughness [Online] Available at https://engineering.purdue.edu/ME556/Documents/Surface%20Roughness.pdf

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.