Digital Surf and Bruker, a global leader in advanced surface metrology, have designed a fully integrated analysis solution based on the Mountains® platform, facilitating unparalleled throughput for quality control in precision manufacturing. This was following an initial partnership agreement that was announced in 2016.

Author of the article: Samuel Lesko, Director of Technology and Applications at Bruker. Image Credit: Bruker

The Challenges Associated with Advanced Manufacturing

Over the past decade, while the production and manufacturing industries have evolved rapidly, they have faced considerable challenges both in finding resources to run production but also in manufacturing under more stringent tolerances for surface texture and 3D feature dimensions.

Due to the strict tolerances necessary in advanced manufacturing, there is a need to have extremely repeatable metrology systems as part of the manufacturing line. Often, a robot is deployed to exchange parts between the production tool and metrology equipment, creating a fully automated process that eliminates some of the variability that human operators have.

Through the same automation path, results from a metrology tool are transmitted to a central server that tracks all trends or abnormalities (Statistical Process Control, SPC). This development is generally known as Industry 4.0, where manufacturing is highly automated and integrated directly with surface metrology.

Features for Quality Control

The advanced precision engineering industry produces numerous parts for different sectors, including medical (orthopedic hip cup, knee joint, etc.) and automotive (injector, cylinder, etc.)

In each of these applications, areal texture and roughness, local flatness, and topographic defects or deviation of three-dimensional (3D) features play an essential role in meeting the efficiency/functionality for moving mechanical parts and certification compliance requirements for medical devices.

Surface metrology tools used in Industry 4.0 applications must not only be able to measure but also generate and save reports automatically with dynamic naming, log results in a database combined with batch ID and/or part number and apply state-of-the-art 3D dataset processing to achieve the appropriate parameters required.

Integrating Measurement Automation and Software Analysis

To fulfill these requirements, Bruker and Digital Surf came together to deliver full integration of measurement software acquiring data from a white light interferometry (WLI) optical profiler with Mountains® analysis software.

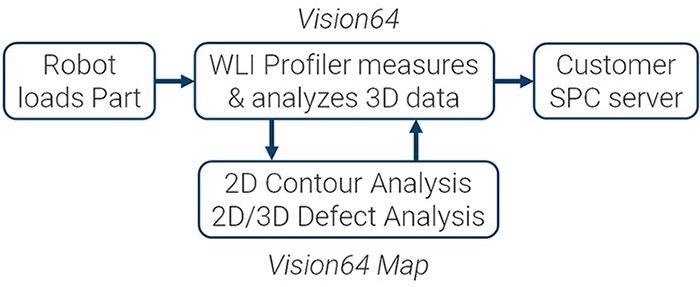

Robot inputs, such as part serial number or measurement conditions (objective, measurement mode, etc.), are transmitted to Bruker’s Vision64 measurement software, and results such as diameter variation or classification of defects are acquired by direct communication with Vision64 Map analysis software (see figure below).

Image Credit: Digital Surf

The measurement software effortlessly communicates with Digital Surf’s sophisticated surface and contour solutions in either direction. Due to this bi-directional data exchange, the measurement software can save and/or print a report automatically for each part measured. It also has the capacity to report results to an SPC server via a comma separated variable (CSV) file.

Bruker’s WLI optical profiler advances the high throughput requirements with rapid large areal topography measurement pairing sub-nanometer vertical and sub-micron lateral resolutions.

Combined with the particle analysis, defect classification, and sophisticated contour abilities of Vision64 Map, it offers an exceptionally powerful analysis solution, successfully meeting the demands of metrology automation.

Automotive Injector Inspection

The analysis of an automotive injector serves as one such example of this fully integrated process. This application demands close control of a number of aspects that are all equally crucial for the part’s quality, based on a single measurement.

Automotive injector inspection report with scratch and pits defect analysis on top surface. Image Credit: Digital Surf

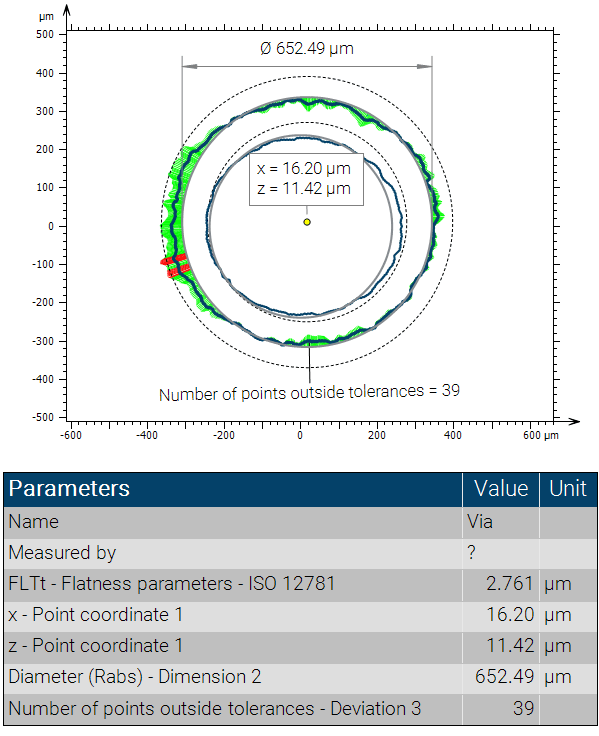

Diameter size and roundness with quantification of deviations are evaluated automatically using state-of-the-art contour tools while screening of flatness and vertical defects is conducted through the parameters table and particle analysis features.

Establishing the most prevalent surface defects is further determined via the classification tool, thus drawing attention to scratches, which can be responsible for leak paths.

Finally, the relative shift between top and bottom diameter is calculated automatically using the advanced contour tool.

Deviation versus desired diameter. Image Credit: Digital Surf

Conclusion

The complete integration of Bruker’s WLI optical profiler acquisition system and Mountains® software analyses facilitates quality control in demanding advanced manufacturing processes.

The success of this solution is due to a novel combination of robust and flexible analysis toolkits, such as particle analysis and advanced contour, together with excellent metrological performance. Combined, these components offer a sustainable, dynamic solution to the challenges faced in Industry 4.0.

This information has been sourced, reviewed and adapted from materials provided by Digital Surf.

For more information on this source, please visit Digital Surf.