Ultra-high purity gases are essential across the semiconductor supply chain. Indeed, for a normal fab, high purity gases constitute the biggest material expenditure following silicon itself.

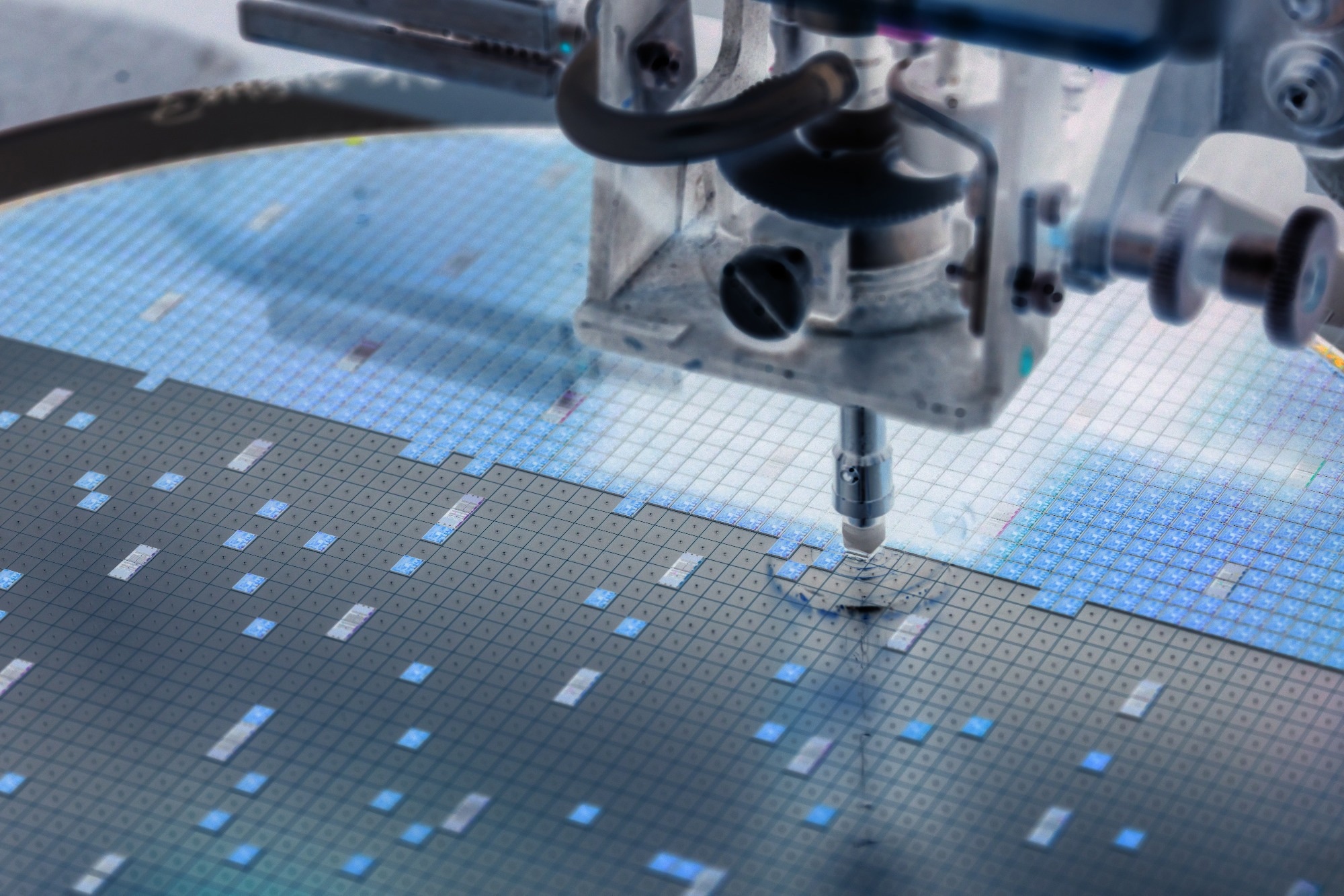

Image Credit: Macro photo/Shutterstock.com

In the wake of the global chip shortage, the industry has been quickly growing — and its demand for high purity gases is also on the rise.1,2

Hydrogen, nitrogen, helium, and argon are the most commonly utilized bulk gases in semiconductor manufacturing.

Nitrogen

Around 78% of the air is constituted by nitrogen, thus it is significantly abundant.3 Also, it is electrically non-conductive and chemically inert. Consequently, nitrogen has found its way into several industry sectors as an affordable inerting gas.

The semiconductor industry is a significant consumer of nitrogen. A modern semiconductor fabrication plant could utilize as much as 50,000 cubic meters of nitrogen an hour.4

As far as semiconductor manufacturing is concerned, nitrogen is used for inerting and purging gas, thereby safeguarding sensitive silicon wafers from moisture in the air and reactive oxygen.

Helium

Helium is a noble gas. This implies, like nitrogen, helium is also chemically inert — but it also has the added advantage of being highly thermally conductive. This is beneficial in semiconductor manufacturing, thereby allowing it to effectively conduct heat away from energetic processes and helping to safeguard them from thermal damage as well as undesirable chemical reactions.5,6

Hydrogen

Across electronics manufacturing and semiconductor production, hydrogen has been widely utilized. Hydrogen is utilized for:

- Annealing: Silicon wafers are subjected to regular heating to high temperatures and then cooled gradually to repair (anneal) the crystal structure. Hydrogen has been utilized to shift heat evenly to the wafer and help the reconstruction of the crystal structure.

- Deposition: Hydrogen could be integrated into thin silicon films to make their atomic structure highly disordered and help increase their electrical resistivity.

- Epitaxy: Ultra-high purity hydrogen has been utilized as a reducing agent in the epitaxial deposition of semiconductor materials like germanium and silicon.

- Plasma cleaning: Hydrogen plasma is especially efficient at eliminating tin contamination from light sources that have been utilized in UV photolithography.7

Argon

Argon is another noble gas and displays low reactivity similar to helium and nitrogen. But, thanks to its low ionization energy, argon is often used in semiconductor applications. Since argon is relatively simple to ionize, it is generally utilized as major plasma gas for etching and deposition reactions in semiconductor fabrication. Besides this, argon has been utilized in excimer lasers for UV lithography.8

Why Purity Matters

Traditionally, progress made in semiconductor technology has been obtained by dimensional scaling. This can be done with new generations of semiconductor technology that have been characterized by smaller feature sizes.

This generates several advantages: more transistors packed into a provided volume, enhanced lower power consumption, current flow, and quicker switching.9,10

But as the crucial dimensions are driven downward, semiconductor devices become increasingly fragile. In a world where the positions of single atoms are significant, fault tolerance thresholds are unbelievably tight. Thus, modern semiconductor processes demand the greatest possible purity from process gases.

Air Products have been developed by the BIP® range of gases to offer the greatest possible level of gas purity for semiconductor applications. Critically, BIP® gases not only provide high purity, but absolute minimum levels of critical impurities like moisture, oxygen, and hydrocarbons.

The proprietary BIP® technology — built into each cylinder — offers extra filtration of gas at the point of use.

All BIP® gases have a minimum purity grade of 6.0 (99.9999% purity). The company ensures the market’s lowest levels of crucial impurities: oxygen (≤10 ppb), moisture (≤ 20ppb), and total hydrocarbons (< 100 ppb). The company also provides specialty gases to the semiconductor industry in a variety of supply modes to fit any consumption rate and applications.

To find out why Air Products is a world-leading supplier of ultra-pure gases to the semiconductor industry – contact a member of the Air Products team today.

References and Further Reading

- Ravi, S. Global Semiconductor Sales Increase 13.2% year-to-year in January. Semiconductor Industry Association https://www.semiconductors.org/global-semiconductor-sales-increase-13-2-year-to-year-in-january/ (2021).

- Welle (www.dw.com), D. The EU’s microchip dilemma: Too little or too late? | DW | 29.04.2021. DW.COM https://www.dw.com/en/the-eus-microchip-dilemma-too-little-or-too-late/a-57367537.

- Laboratory, S. U. H. I. on E. C. A. A. F.-P. S. B. A. B., NASA’s Jet Propulsion. The Atmosphere: Getting a Handle on Carbon Dioxide. Climate Change: Vital Signs of the Planet https://climate.nasa.gov/news/2915/the-atmosphere-getting-a-handle-on-carbon-dioxide.

- Nitrogen Demand Increases for Semiconductor: How Safe Are You? PureAire Monitoring Systems Oxygen Monitor https://www.pureairemonitoring.com/nitrogen-demand-increases-for-semiconductor-how-safe-are-you/ (2016).

- Helium Is Instrumental in Semiconductor Manufacturing. IER https://www.instituteforenergyresearch.org/fossil-fuels/helium-is-instrumental-in-semiconductor-manufacturing/ (2021).

- Semiconductor Industry Association | Testimony of Carolyn Duran, Direction of Chemical Risk and Compliance, Global Sourcing and Procurement, Intel Corporation. https://www.energy.senate.gov/services/files/BE7C9D0C-2043-4BBD-8313-C49CB6356C0E.

- Elg, D. T. Removal of Tin from Extreme Ultraviolet Collector Optics by an In-Situ Hydrogen Plasma. Ph.D. Thesis (2016).

- Tallents, G., Wagenaars, E. & Pert, G. Lithography at EUV wavelengths. Nature Photon 4, 809–811 (2010).

- Moore, G. E. No exponential is forever: but ‘Forever’ can be delayed! [semiconductor industry]. in 2003 IEEE International Solid-State Circuits Conference, 2003. Digest of Technical Papers. ISSCC. vol. 1 20–23 (IEEE, 2003).

- Orji, N. G. et al. Metrology for the next generation of semiconductor devices. Nat Electron 1, 532–547 (2018).

This information has been sourced, reviewed and adapted from materials provided by Air Products PLC.

For more information on this source, please visit Air Products PLC.