Magnesium is often coated with phytic acid to overcome certain functional limitations. This article sheds light on the advantages and limitations of magnesium alloys with phytic acid coatings.

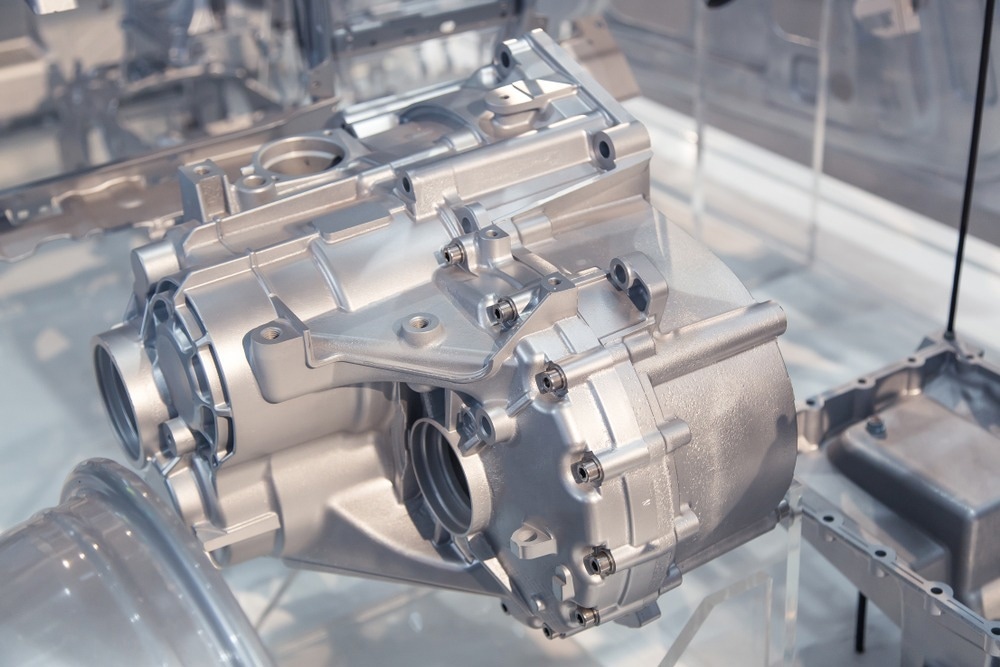

Image Credit: patruflo/Shutterstock.com

Why are Magnesium Alloys Used Extensively?

Concerning industrial implementation as well as research studies, magnesium alloys are the center of attention owing to their light weight and higher strength than ordinary material, natural abundance, and biocompatibility. These alloys have found application in the aerospace industry, electronics manufacturing, automobile industry, and most notably in medical science as orthopedic implants.

Limitations of Magnesium Alloys

Although magnesium alloys are used extensively, the high corrosion rates are a big drawback. They corrode rapidly in highly chlorinated solutions such as human body fluid. This is a massive problem regarding its uses in biomedical applications. However, researchers have found a solution to this problem by utilizing magnesium alloys with phytic acid conversion coatings.

What are Phytic Acid Conversion Coatings?

Phytic acid (PA) is a compound present in a variety of plant-based diets. It is also known as IP6 and inositol hex phosphate. It has been widely employed as a film-former in the domain of anti-corrosion property enhancement of metallic substances by developing chemical conversion coatings. PA, a type of sustainable green biological macromolecule that is safe for the human body, has become a popular corrosion preventive.

Factors Affecting Performance of PA Coatings on Mg Alloys

The latest research published in the journal Progress in Organic Coatings provides a detailed analysis and review of phytic acid coatings on magnesium alloys. As per the research, several factors such as pH, temperature, PA concentration, and treatment time serve as the primary performance affecting parameters.

How do pH and Treatment Time Affect the Performance?

pH provides the optimum conditions for chemical reactions to take place. The research states that the coatings at lower pH had better structural integrity than the ones at higher pH. The fissures in coverings with pH values of 3 and 5 were much greater than those in coatings with pH values of 8 and 10, and the interface of PA coatings with pH values of 8 and 10 was smooth. The pH 5 coating had the highest corrosion protection, whereas the pH 10 coating had the quickest corrosion rate.

The width and homogeneity of PA coatings are affected by the conversion time. As transformation time is increased, the thickness, density, and reliability of the coating increase, as does the resistance of the coating. When the conversion period is very short (less than 15 minutes), the creation of the PA coating is incomplete or the covering is fairly thin, resulting in a poor capacity to repel corrosive ions.

How do PA concentration and Temperature Affect the Coatings?

The kinetics of chemical changes can be affected by temperature. The temperature at which the PA coating is formed impacts not only the intercalation rate of the Mg matrix and PA but also the rate of hydrogen generation, affecting the uniformity and the inherent resistance to corrosion.

The reaction is modest at approximately 25 degrees Celsius; a few bubbles accumulate around the specimen, the fissures are insubstantial, and the covering is thin. When the temperature climbs to 40 degrees Celsius, the process becomes considerably more intense, and the H2 exits considerably more quickly.

PA content has a direct influence on the number of reagents in the solution, which affects coating adhesion. The PA coatings are often homogeneous and comprehensive without fractures at low concentrations (1–5 g/L). At a lower Phytic acid concentration, the speed of coating production is comparatively sluggish due to the tiny number of reagents in the solutions, resulting in a relatively thin coating.

Micro Arc-Oxidized Mg Alloys and Phytic Acid Coatings

Yang et. al has published research in the Chemical Engineering Journal which provides a simple and environmentally friendly method for preparing phytic acid/cerium composite coating (PA/Ce) with self-healing capacity on micro-arc-oxidized magnesium alloy using hydrothermal processing.

Micro-arc oxidation (MAO) is a powerful technique for improving the corrosion characteristics of materials. It may build a dense ceramics special covering with exceptional performance on the metal surface, with excellent abrasion and corrosion resistance.

To improve the interfacial bonding between salt particles and the micro-arc oxidation (MAO) layer, organic non-toxic phytic acid was utilized as an intermediary chelator.

The results demonstrated that the as-prepared MAO/PA composite covering with a depth of about 5 m was compact and homogenous and that it adhered effectively with the Mg foundation. Electrochemical testing revealed that the layer boosted resistance to corrosion substantially. Furthermore, the layer demonstrated self-healing properties and may provide long-term protection against corrosion.

Alternatives to PA Coatings?

As an alternative to PA coatings, preparation methods of layered double hydroxides (LDHs) for Magnesium alloys have been reported in Coatings. LDH is a sort of hydrotalcite-like substance made up of two or more metals with a multilayer hydroxide composition.

One of the most appealing techniques for manufacturing LDH intercalation substances is co-precipitation (CPT). LDH coverings generated by CPT and hydrothermal methods have exceptionally low corrosion current density, making them a potential material for nonchromium chemical and electrochemical coating of Mg alloys.

It also reported the one-step in-situ growing process as a potential way for directly synthesizing LDH coatings on the Mg alloy platform and considerably improving the mechanical characteristics and interface adherence of the coating.

It also mentions steam coating, a method of producing magnesium alloys corrosion protection covering without the need for synthetic steam by employing ultra-pure freshwater as a vapor origin.

Future Research

Although PA has outstanding biocompatibility, several issues are expected to be the subject of future studies. PA may complicate with metal ions to produce a balanced metal-PA complex because it possesses many active oxygen ligands.

However, the chemical mechanism of PA complexation with metal has not been investigated. When coupled with an inorganic salt, it is easy for destabilizing phenomena to emerge and even crystallize; this flaw must be remedied. Finally, whether the bioactivity of PA is reduced when mixed with other coverings must be evaluated by in vitro and in vivo biological tests.

In short, PA coatings have played a substantial role in the commercialization of magnesium alloys with future research expected to overcome the problems currently faced during applications of PA coatings on metal substrates, especially magnesium.

More from AZoM: Reviewing the Use of Computational NIR Spectroscopy

References and Further Reading

Xu Y. et. al. (2022). Biodegradable phytic acid conversion coatings on magnesium alloy for temporary orthopedic implant: A review. Progress in Organic Coatings. 169. 106920. Available at: https://doi.org/10.1016/j.porgcoat.2022.106920

Yang S., Sun, R., & Chen, K. (2022). Self-healing performance and corrosion resistance of phytic acid/cerium composite coating on microarc-oxidized magnesium alloy. Chemical Engineering Journal. 428. 131198. Available at: https://doi.org/10.1016/j.cej.2021.131198

Zhang X. et. al. (2021). Active Corrosion Protection of Mg–Al Layered Double Hydroxide for Magnesium Alloys: A Short Review. Coatings. 11(11). 1316. Available at: https://doi.org/10.3390/coatings11111316

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.