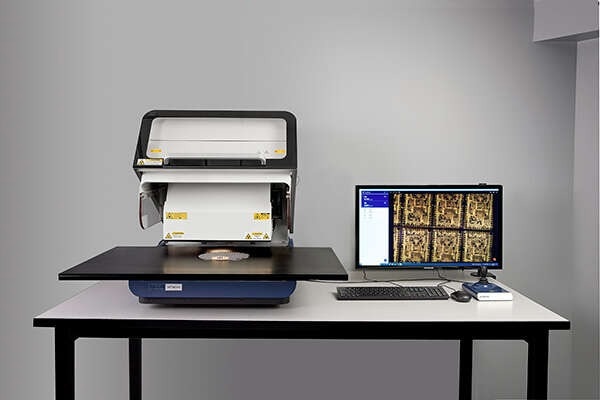

The FT230 coatings analyzer is one of the best reasons for users to step outside of their comfort zone and start to use a new XRF coatings analyzer.

Image Credit: Hitachi High-Tech Analytical Science

Time is Money; Get Results Faster

The time it takes to locate a part, set it up in the XRF and act on the results has a significant impact on production efficiency and the cost of materials. The more time it takes, the more material plated – if that material is out of spec, it has to be scrapped for a total loss. However, if the material is in spec, users can still end up applying more coatings and use more chemicals than absolutely necessary.

The FT230 has been developed to shorten that time so that quicker decisions can be made. Here is how and the results to expect:

- Wide-view camera: The first step to take when using an XRF measurement is finding the measurement location. While the camera that comes as standard in most XRF analyzers is well-suited for fine-tuning, it can be difficult to navigate a larger part to find specific features.

The wide-view camera allows the operator to see the entire measurable area and make sure the right features are selected (assisted by powerful zoom), which brings the feature to the crosshairs. This can save 20% of your setup time.

- Automated focusing: Once the location has been set, the operator must focus the part. With conventional instruments, this is completed using the focus laser or video focus.

The FT230 has the ability to use a focus laser but also provides two automated focusing features to accelerate and simplify this step. The auto approach measures the distance from the X-Ray tube to the part and drives the tube to the predetermined working distance automatically.

The auto approach can be 33% faster than a focus laser.

Auto focus, sometimes referred to as the distance independent measurement, also measures the distance between the X-Ray tube and the part, but rather than moving the tube, it ensures the tube remains at the same height and uses that distance to correct the new geometry.

Auto focus allows users to load parts of varying heights or measure parts that are recessed or stepped, and can be 62% faster than using a focus laser.

- Find My PartTM: For ultimate simplicity, the user only has to teach the instrument how to handle a part once. From that point on, the operator simply places a part into the instrument, runs Find My PartTM, and, utilizing machine vision, the FT230 is able to recognize the part and load the complete analysis routine – calibrations, collimator sizes, measurement locations, working distance, measurement time and what to do with the results.

Find My PartTM can be 72% faster – or quicker – than a traditional setup. It is also possible to load measurement routines by simply using name lookup and scanning a QR or barcode.

Easy, Powerful Software

When an XRF coatings instrument is used, almost all of an operator’s time is consumed by the measurement screen. With the all-new FT Connect software on the FT230, Hitachi High-Tech puts the operator first to ensure easy analysis.

- New, smart software: Today’s software platforms are generally based on design requirements, limitations, and user preferences from years ago. While they include several invaluable features, training new operators can be difficult since interfaces have moved on a lot since these tools were first developed.

Over the last twenty years, the software on your phone, tablet, computer, TV, car and even your toaster has advanced considerably. With FT Connect on the FT230, the software for XRF coatings analyzers can meet the demands of modern industry.

- The user comes first: In contrast to previous software platforms, FT Connect completely inverts the user interface. Rather than having a small view of the part surrounded by buttons, controls, and settings, the FT Connect measurement screen is able to focus on the two most crucial tasks that an operator needs to focus on: setting up a measurement and how to act on the results.

Occupying 60% of the screen, FT Connect has the largest sample view display on the market and it also has extremely flexible lighting controls. The user can regulate dozens of LEDs either as rings, wedge segments, or individually to make sure they have the best possible view.

The factory pre-set suggestions can also be used, and it is possible to generate new customized lighting setups to streamline future measurements.

Results are clearly displayed next to the camera view with tools for trend and statistic assessment, generating reports, or exporting results and looking at historical results. Each result card can be easily expanded to view further details about previous measurements for rapid interpretation.

The data handling capabilities are Industry 4.0 ready. Results can be exported in comprehensive JSON format or spreadsheet form for integration with SCADA, QMS, MES or ERP systems.

Global Support to Keep Users Up and Running

At Hitachi, support does not end as soon as the FT230 has been installed. The company works with clients throughout the instrument’s lifetime to ensure full support is on hand – whether that be to offer additional training, technical support, routine maintenance, including preventive maintenance and certification or repairs.

- Expert support, globally: Hitachi has offices in the US, UK, Germany, India, China, and Japan which offers world-leading technical support and applications development capabilities. Hitachi’s global team of factory-trained partners is a welcomed addition to its offices, as the team is equally committed to customer satisfaction.

- Remote diagnostics: the FT230 has numerous layers of diagnostics to ensure the XRF is performing as expected. It comes as standard with an instrument health check, has a daily check feature to validate your calibrations before production parts are measured and can run detailed instrument diagnostics.

Share selected diagnostics data directly and automatically with Hitachi’s expert support team using ExTOPE Connect, cloud-based data management and storage solution. This is the quickest way to get the data to Hitachi engineers.

The instrument can be quickly evaluated to pinpoint the precise problem area before going on-site. This helps to ensure that the engineer has access to the right parts to get clients up and running as quickly as possible.

The FT230 is just one of many solutions for the coatings industry. Hitachi offers a wide range of dedicated instruments: electromagnetic gauges for paint, anodizing, and PCB copper thickness, XRF coatings analyzers, handheld XRF for coatings and materials analysis, instruments with extensive capabilities for solutions analysis and thermal analysis instruments for proper materials properties testing.

Take a closer look at Hitachi products and make the switch today.

This information has been sourced, reviewed and adapted from materials provided by Hitachi High-Tech Analytical Science.

For more information on this source, please visit Hitachi High-Tech Analytical Science.