Following ChemUK 2022, we spoke with Holiferm, a University of Manchester spin-off hoping to turn home and personal care products green with their eco-friendly biosurfactant products. Here, we discuss their sustainable alternatives to petrochemicals and the award-winning gravity separation fermentation technology behind their chemical processes.

Please could you introduce yourself and tell us about your role within Holiferm?

My name is Richard Lock and I am the Managing Director of Holiferm. I am in charge of the commercial side of business, overseeing the build of our commercial plant and the manufacture and distribution of our products to clients and customers.

How did you initially become involved with machine learning technologies, particularly their application to the chemical industry?

We became involved with machine learning technologies during the build of our pilot plant in Daresbury. We looked into them as a way of making our processes more productive and reliable.

We have taken the lessons we learned from the pilot plant and have applied them to our current project, building our first commercial plant at Ocean Park in Wallasey. The aim is to have this operational by early 2023.

Who are Holiferm, and what are its mission statements?

Holiferm is a biosurfactants producer. We are a spin-out from the University of Manchester, where our CEO, Ben Dolman, designed our patented gravity separation fermentation technology.

Our biosurfactants have a wide range of applications in the cosmetics, personal care, home care, agriculture and oil and gas industries. Our mission is to facilitate the manufacture of holistically sustainable bioproducts at a value point at which they are affordable to everyone, therefore eliminating the need for petrochemicals.

Just as importantly, we want to enhance the lives of our employees and external stakeholders by working collaboratively by always looking for mutual benefit and providing opportunities for growth and impact.

© Holiferm

Could you give an overview of the different products that Holiferm provides?

We currently have five products available. HoneySurf LF and HoneySurf HF can be used as part of home care and industrial cleaning formulations, while HoneySurf AG can be used for agricultural purposes. HoliSurf LF and HoliSurf HF can be used in cosmetics and personal care products.

We are working on a number of other molecules and products which we hope to bring to market in the near future.

Holiferm recently attended the CHEMUK exhibition; as we enter a state of post-pandemic normality with an increase in in-person events, what benefits can such events have for start-up companies like yourself?

The benefits of face-to-face events are enormous for a start-up company such as Holiferm. They allow us not only to meet potential new partners and customers, but more importantly, for people to get hands-on with our product whilst we explain the benefits to them. This type of interaction allows for a more meaningful dialogue where we are able to discuss possible new uses for our products and explore formulation ideas.

Events, such as CHEMUK, also allow us to have a much greater reach within the industry, leading to many more links made with industry experts and companies we haven’t worked with yet.

What are biosurfactants, and how do they compare to formulations currently available?

Biosurfactants are essentially surfactants produced using naturally occurring ingredients in a natural process. They remove the need for petrochemicals to be used during production, which saves 1.5 tons of CO2 per ton produced and uses 50% less energy than traditional processes. This has a massively beneficial impact on the environment.

We have had our biosurfactants tested using an in vitro test created by XCellR8. Our biosurfactants were tested alongside other similar compounds and were found to be milder on the skin and were classified as ultra-mild, as no skin irritation was seen up to 48 hours after application.

© Holiferm

Petrochemicals are an essential component of the chemical industry, yet their fossil fuel-based origin raises many environmental concerns. What more can be done to reduce reliance on these chemicals, and how can members of the chemical community work to increase awareness of sustainable solutions?

We are one of a number of start-up companies that have this concern at the heart of everything we do. At the moment, the biggest barriers are awareness and willingness to change. We need to do everything we can to publicize our message and make others aware that there are alternatives available and that they are as good, if not better than the petrochemical produced compounds.

To this end, we use social media, events, marketing, articles and conferences to inform as many people, customers and companies as possible about the alternatives to petrochemicals.

© Holiferm

Integrating sustainable practices involves not just the chemical products that are produced but also optimizing the processes involved. Could you discuss how Holiferm approaches this with technologies like your integrated gravity separation and fermentation methodology?

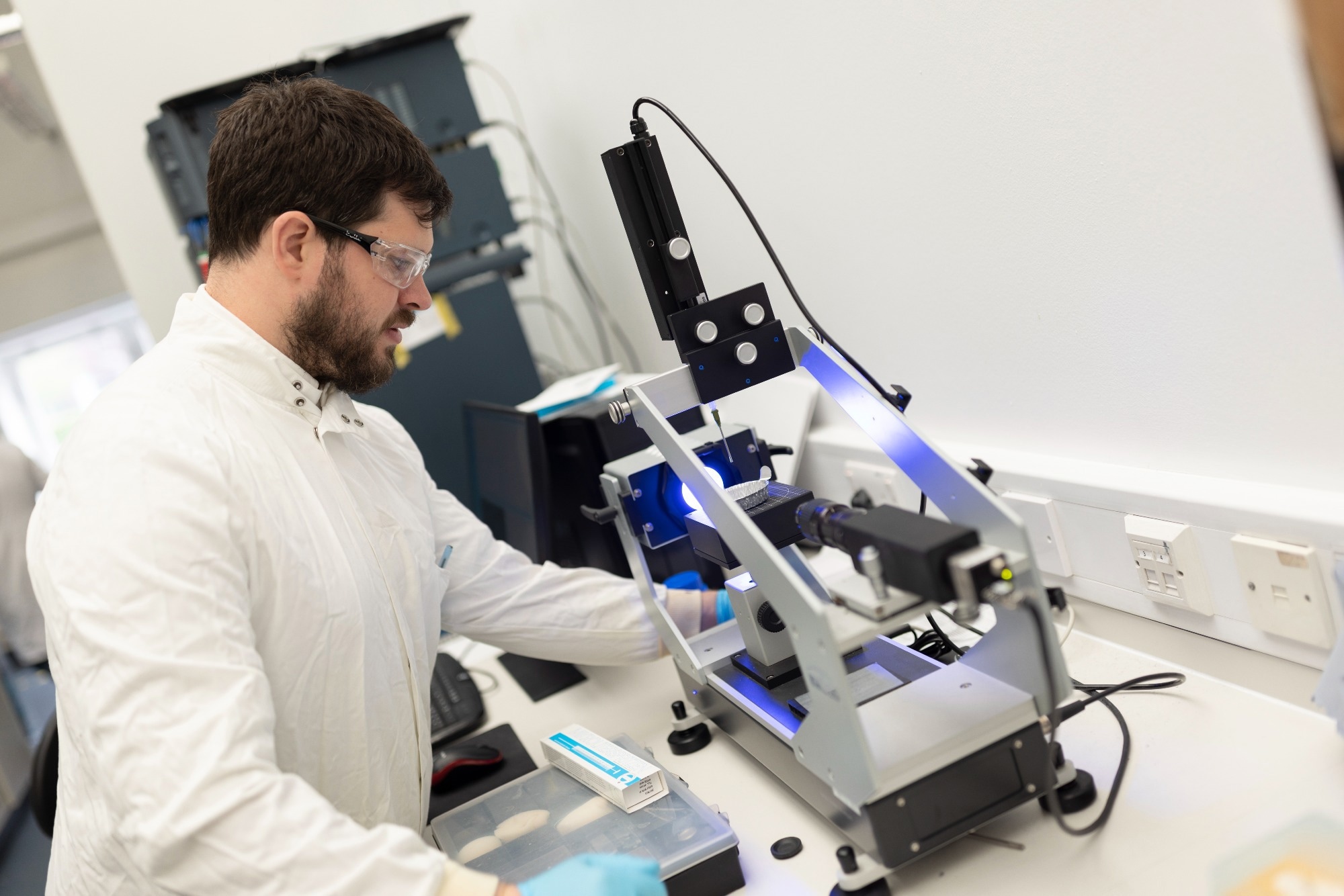

Our patented and award-winning gravity separation fermentation technology is a real asset to us. It allows us to use a continuous cyclical production method, which is more efficient and cost-effective than the norm of batch production.

We are also able to take samples at any stage of the process and test them to ensure our products remain of consistently high quality. This optimization of our process means we can manufacture our products more quickly and at a competitive price point for our customers.

Could you discuss Holiferm’s recent partnership with Sasol, and the benefits this collaboration will bring?

Sasol’s partnership with us is an important step in our journey. It was the first major sign that larger-scale companies were listening to us and understanding what we are trying to do.

The partnership with Sasol has two main parts. The first is the agreement to buy over half the biosurfactants produced at our commercial plant in Wallasey. This guarantees our plant will be sustainable and profitable.

The second is an agreement to work together on new research and development projects, which will apply our technology to a range of different molecules.

What do the next few years look like to Holiferm? Are there any innovations the company is striving towards?

The future is looking very bright for Holiferm. We hope to have our commercial plant operational in early 2023 and hit our initial target rates, and hope to be able to increase the capacity of the plant to supply our products to more customers and distributors.

We are also looking into a number of different molecules, which we hope to be able to work on using our technology and innovative ideas and practices. Longer term, we hope to open a second commercial plant, perhaps in partnership with another company or alongside a business that has waste streams that we can use.

About Richard Lock

Richard has an impressive chemical portfolio, having worked for a number of companies in the sector such as Libra and Innospec. He has supported multinational yearly revenue generation of £28.5 million, with a proven organic growth, and grew EBTIDA from 12% to 16% between 2018-2019.

Richard has an impressive chemical portfolio, having worked for a number of companies in the sector such as Libra and Innospec. He has supported multinational yearly revenue generation of £28.5 million, with a proven organic growth, and grew EBTIDA from 12% to 16% between 2018-2019.

Richard has created a commercial business case to build a 36,000 tpa £3.5 million betane plant and agreed supply contracts for 1000s of tons.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.