The laser flash diffusivity method is one of several methods to measure the ability of a material to diffuse heat. This is useful when there is a need to determine how a material will behave in environments with changing temperatures. Importantly, the laser flash diffusivity method offers several advantages over other thermal analysis methods.

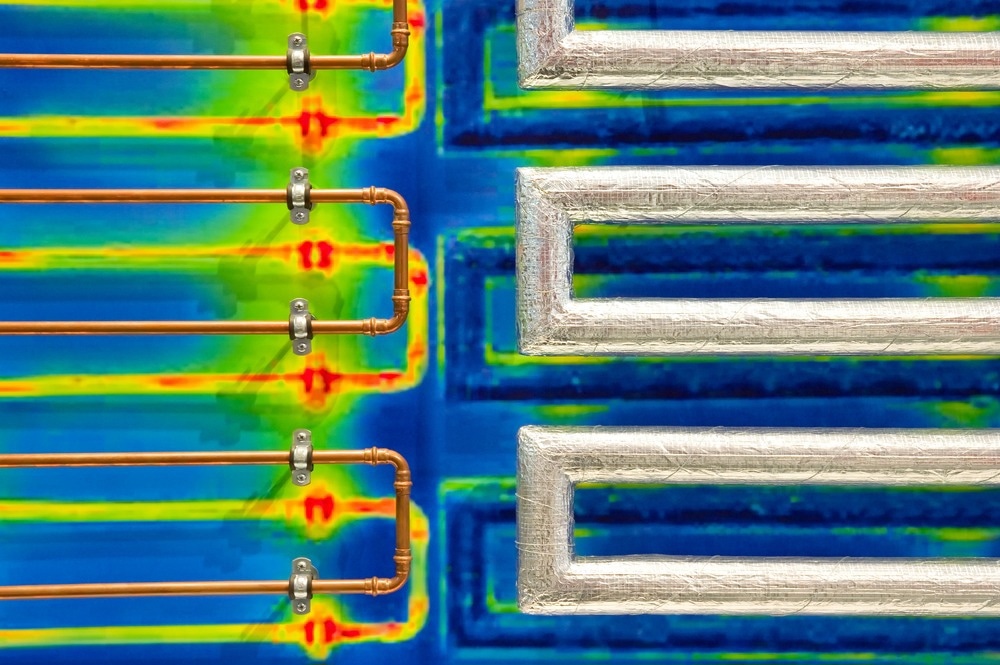

Image Credit: alterfalter/Shutterstock.com

In this article, we discuss the laser flash diffusivity method’s working principle, applications, its advantages over other methods, and finally its limitations and research directed towards mitigating them.

What is Laser Flash Diffusivity Method and How Does it Work?

The laser flash diffusivity method is used to measure a material’s ability to diffuse heat, also known as the material’s thermal diffusivity. Its working principle is quite simple.

The apparatus consists of a thermal source which can be a laser or flash lamp, a sample, and a temperature detector. The laser flash serves as a thermal source that heats the sample on one side. The sample then absorbs the heat energy and emits some on the rear side. The thermal detector is positioned on the rear side of the sample and detects the changes in temperature in a time-dependent manner.

Therefore, the faster the temperature rises at the rear end of the sample, the higher the thermal diffusivity. This information can fit suitable models that can be used for prediction purposes.

Other parameters such as thermal conductivity can be calculated from the thermal diffusivity when the material’s density and its specific heat capacity are known.

What is the Laser Flash Diffusivity Method Applied to?

Thermal diffusivity is also a representation of how fast a material can react to temperature changes. It permits an understanding of a material's capacity to function in systems exposed to changes in temperature. This enables the prediction of cooling processes and effectively simulates temperatures in fields. It is used especially in the development of thermal interface materials, which can be used in medical devices, electronics, polymers, plastics for food preservation, pharmaceuticals, etc.

How Does the Laser Flash Diffusivity Method Compare to Other Thermal Analysis Methods?

Other methods that can be used to measure a material’s ability to diffuse heat include the hot wire, the guarded hot plate, and the heat flow meter methods. Some disadvantages of these other methods that are not an issue in the laser flash diffusivity method include the complexity of the hot wire method, requiring a very skilled operator, the long measurement times and heat flow meters of the guarded hot plate method, and the frequent measurement uncertainties due to calibration.

Laser flash diffusivity is mainly advantageous in that it can rapidly measure in a non-destructive manner the diffusivity of samples with a wide range of conductivities. It also requires less tedious sample preparation, and small samples can be used as well.

Limitations of the Laser Flash Diffusivity Method

First, the laser flash diffusivity method works best with materials that have homogeneous structures because material properties such as porosity can affect thermal diffusivity. This effect is increasingly important as the thickness of the material increases. Hence, care is often required as this can also affect other parameters that are calculated considering diffusivity values.

Secondly, heat can also be lost in other directions to the environment, which can cause considerable temperature fluctuations across the observed temperatures, hence making modeling more difficult.

Thirdly, the cost of fast laser sources and fast detection systems is quite high, and they can be quite complex. These are more efficient for measuring diffusivity on micro-scale materials like thin films.

Measurement errors can ensue because of the finite pulse-time effect. This occurs because a laser pulse emitted for a finite amount of time results in longer times to observe temperature changes on the sample’s rear side. Research towards mitigating the limitations of the laser flash diffusivity method is being conducted.

In a study published in the International Journal of Heat and Mass Transfer, researchers attempted to derive new formulas to mitigate the effects of arbitrary pulse shapes and both homogeneous and heterogeneous samples with two layers of different materials. The resulting calculations had potential and practical applications in noisy discrete heat pulse measurements.

Another attempt at improving thermal diffusivity measurements was reported in the International Journal of Thermophysics. The researchers included in the laser flash method a detector with an inherent delayed response. A transfer function was derived from the measurements of the detector signals of direct laser pulses to correct systematic errors.

The function was then used to efficiently reduce the detector's inherent delayed response and the finite pulse-time delay because the detector-related time delay was now inherent to the system.

Concluding Remarks and Future Directions

The laser flash diffusivity method is undoubtedly an effective method for determining the thermal diffusivity of materials, although it is prone to errors when materials with non-homogeneous structures are used. It is important to keep this in mind when using this method as erroneous information can affect other calculations that depend on it. More research to improve the effectiveness of the laser flash diffusivity method should be aimed at overcoming heat transfer issues that hinder the accuracy of measurements.

More from AZoM: What is Glow Discharge Optical Emission Spectrometry

References and Further Reading

Linseis Messgeräte GmbH (2020). Laser flash method -Thermal diffusivity determination. [Online] linseis.com. Available at: https://www.linseis.com/en/methods/flash-method/

Breuer, S., and Schilling, F. R. (2019). Improving thermal diffusivity measurements by including detector inherent delayed response in laser flash method. International Journal of Thermophysics, 40(10), 95. https://doi.org/10.1007/s10765-019-2562-9

Carr, E. J., and Wood, C. J. (2019). Rear-surface integral method for calculating thermal diffusivity: Finite pulse time correction and two-layer samples. International Journal of Heat and Mass Transfer, 144, 118609. https://doi.org/10.1016/j.ijheatmasstransfer.2019.118609

Lindemann, A., Blumm, J., and Brunner, M. (2014). Current limitations of commercial laser flash techniques for highly conducting materials and thin films. High Temperatures - High Pressures, 43, 243–252.

Nunes dos Santos, W., Mummery, P., and Wallwork, A. (2005). Thermal diffusivity of polymers by the laser flash technique. Polymer Testing, 24(5), pp. 628–634. https://doi.org/10.1016/j.polymertesting.2005.03.007

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.