AZoM speaks with Sona Dadhania, a Technology Analyst at IDTechEx, about the role 3D printing will play in the future of industrial manufacturing.

Please can you introduce yourself and your professional background?

My name is Sona Dadhania, and I am a Technology Analyst at IDTechEx with a primary focus on 3D printing and secondary interests in advanced materials and healthcare. I lead IDTechEx’s 3D printing market research to provide key technology and market insights into this dynamic field. My most recent publications include reports on 3D Printing Materials, Metal Additive Manufacturing, and Ceramic 3D Printing.

Prior to joining IDTechEx, I researched 3D printing materials at the University of Pennsylvania and Imperial College London, where I earned my master’s and bachelor’s degrees in Materials Science and Engineering.

IDTechEx provides insights into markets to give clients a deep technical understanding of existing and novel technologies. With this expertise in mind, how significant is additive manufacturing as an emerging technology?

IDTechEx has viewed additive manufacturing as an important emerging technology for years now, having covered the topic since 2014. We see 3D printing as a core contributor to the future of advanced manufacturing, especially with the rise of Industry 4.0 and related technologies changing how manufacturing is accomplished. Current supply chain disruptions are also bringing new significance to 3D printing; these issues have exposed the flaws of globalized manufacturing and renewed discussion on distributed or localized manufacturing, of which additive manufacturing is a key component.

What has so far limited the uptake or large-scale use of additive manufacturing?

Historically, additive manufacturing has been limited by numerous factors. One was the misguided thought that additive manufacturing could act as a one-to-one replacement for established manufacturing techniques, such as injection molding. However, this mindset ignored that 3D printing, with its many diverse technologies, is a completely independent technology with its own advantages and disadvantages.

Image Credit: asharkyu/Shutterstock.com

Another challenge has been end-users’ lack of experience and knowledge to integrate additive manufacturing successfully and meaningfully into their business, which often relegated 3D printing solely to the application of prototyping. Lastly, the limited number of compatible materials available for end-users has historically prevented 3D printing’s application in more interesting and demanding environments.

These factors, in tandem, made end-users reluctant to adopt 3D printing, as they did not fully understand where it could fit into their business.

What needs to be done to overcome these limitations?

There is a change in mindset currently occurring that hinges on the recognition of additive manufacturing as its own technology rather than a straight replacement for established techniques. Now, end-users are beginning to think more critically about the value-add that 3D printing brings to their business and supply chain, whether it be as a source of custom tools, jigs, and fixtures; as a method for building complex designs otherwise impossible to achieve; or as a production tool capable of manufacturing at many different volumes.

Essential to this change in mindset is application development, which more and more printer manufacturers and materials companies are undertaking to continue effecting this change in mindset. It is precisely when people can visualize the difference that 3D printing brings to their value chain that additive manufacturing, particularly industrial level, will begin to take off.

Could you describe which materials have the most potential for additive manufacturing, in your opinion?

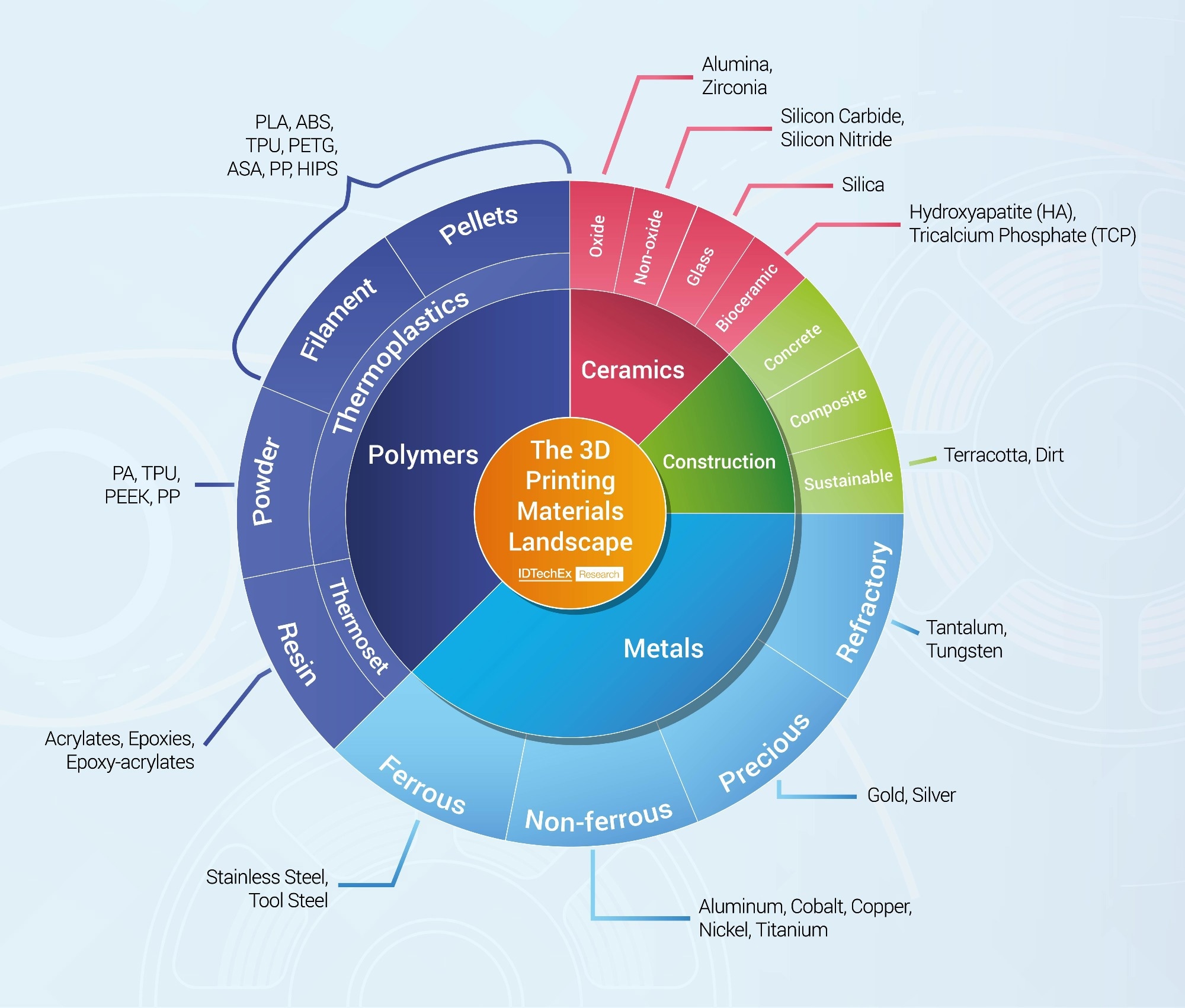

Resins, filaments, inks, powders, wires – additive manufacturing is awash with different materials in diverse feedstock forms, expanding far beyond the PLA filament classically associated with 3D printing. In fact, expanding the additive materials portfolio is critical for additive manufacturing to reach its full potential; engineers will require a diverse toolkit of materials to tackle different applications and challenges.

Each of these material categories will have their own place within this industry, which IDTechEx forecasts to hit $29.5 billion in market size by 2032; however, the materials with the greatest growth potential are those with more functionality.

As increased adoption comes from more end-users really understanding the value-add that AM brings to their supply chain, more functional and higher value materials will see more demand to match AM’s usage in more demanding applications. This includes composite materials of all matrix types, such as fiber-reinforced polymer composites and metal matrix composites.

Additionally, specialized materials geared towards specific applications, like biocompatible resins for implants or ceramics developed for the space environment, will see more interest again as end-users seek to use AM in more functional applications.

You are chairing a talk at the Advanced Materials Show at the NEC on June 29th looking at harnessing the power of additive manufacturing in advanced materials. Could you describe some of the key points you will cover in this presentation?

In this presentation, I intend to give a high-level market overview of additive manufacturing materials to give attendees more context behind the specific topics in advanced materials that my panelists will discuss. The main question I will be answering is what’s next for AM materials?

It is essential for the portfolio of additive manufacturing-specific materials to expand for the market to continue reaching new markets. However, the many different types of materials, from thermoplastics to thermosets, fiber-reinforced composites to metals, ceramics to biomaterials, are all at different stages of maturity and penetration. Additionally, there is significant movement in the industry from a market perspective, given the many acquisitions, expansions, partnerships, and funding rounds taking place. In this talk, I intend to explore the micro-trends in different material classes, especially advanced materials, driving the AM materials market forward.

What kind of opportunities will a greater uptake of 3D printing technology allow across manufacturing industries?

These opportunities are quite industry-dependent. For example, increased use of 3D printing assists electrification efforts as it supports the lightweighting of many components. In healthcare, it allows for fully customized medical devices made from patient imaging. In manufacturing, it acts as both a method for volume production and as a tool for the support and repair of other production techniques.

From a global perspective, additive manufacturing is critical to the vision of achieving localized manufacturing and virtual factories. Instead of the current paradigm where massive quantities of products are made in Asia and shipped globally to wait in warehouses, localized manufacturing presents the opportunity for products to be made on-demand close to their destination. Additive manufacturing is one of few manufacturing technologies that can fulfill that.

How important are conferences like the Advanced Materials Show for progressing discussions around new technologies and manufacturing methods?

Conferences like the Advanced Materials Show present an important forum for many stakeholders, from printer manufacturers and material suppliers to researchers and other end-users, to interact. From these discussions, not only can stakeholders better understand the important issues at hand but also can familiarize themselves with potential solutions to these problems. As a whole, these conferences all contribute to the forward progress of additive manufacturing and other emerging technologies.

About Sona Dadhania

Sona Dadhania is a 3D Printing Analyst at IDTechEx with secondary interests in advanced materials and healthcare. She leads IDTechEx’s 3D printing market research to provide key technology and market insights into this dynamic field. Her most recent publications include reports on 3D Printing Hardware, 3D Printing Materials, and Metal Additive Manufacturing. Prior to joining IDTechEx, Sona researched 3D printing materials at the University of Pennsylvania and Imperial College London, earning her master’s and bachelor’s degrees in Materials Science and Engineering.

Recent Written Articles:

https://www.printedelectronicsworld.com/articles/26932/3d-printing-materials-a-29-5-billion-opportunity-ripe-for-innovation

https://www.printedelectronicsworld.com/articles/26233/metal-additive-manufacturing-rebounds-to-hit-18-billion-by-2032

https://www.printedelectronicsworld.com/articles/26806/metal-3d-printing-technology-landscape-the-trends-and-the-whitespace

https://www.printedelectronicsworld.com/articles/26567/metal-additive-manufacturing-dont-tell-me-show-me

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.