Glass making dates back to ancient Mesopotamia, an astonishing 4,000 years ago. Known as “humankind’s most important material,”1 glass is ubiquitous in our modern environment.

It is used in the construction of skyscrapers, allowing light into our homes, working as an integral substrate for smartphones and electronic devices, as prescription lenses for glasses that help us see better, the windscreens on vehicles, and the fiber optic glass cables that connect the world.

Recent decades have seen an increase in new glass-based technologies such as ultra-thin flexible glass and touchscreens for the newest foldable devices.

Advances in “smart glass” fabrication are now moving the material in a new direction, as technological progress and the parallel trends of digitization and displays are helping to generate more and more dynamic glass applications.

What is Smart Glass?

Effectively, smart glass is manufactured with special layers or coatings that offer functional characteristics. These functions can include:

- Adjustable tint – Some types of smart glass respond automatically to changes in sunlight or can be electronically controlled to change from transparent to tinted or opaque.

- Heat & noise blocking – An assortment of smart glass treatments means that windows in houses or automobiles are able to lower heat transmission and reduce noise.

- Displays – Smart glass with an embedded electrical layer can be used to display images or act as an interactive touchscreen.

- Solar power collection – Inserting photovoltaic cells within layers of glass makes it possible for a vehicle sunroof to double up as a power source to complement battery power.

Not to be confused with “smart glasses” — the augmented-reality devices typically worn on the head — smart glass has extensive application potential in industries such as architecture, aerospace, and automotive.

Amongst the earliest smart glass products were Transitions®, spectacles that transform from clear to tinted when a wearer steps into the sun. The photochromic glass used in this way was first commercialized in the 1960s.

Adjustable-tint photochromic glass lenses used in Transitions® progressive eyeglasses. (Image Source)

The architecture and construction industries have been quick in the uptake of smart glass. When erecting residential and commercial buildings, smart glass offers several benefits. Reducing the amount of UV and sunlight that enters a building to help keep it cooler, saving on the air conditioning use, thus conserving energy and reducing the carbon footprint.

Blocking out the glare of the sun not only offers increased levels of comfort but also prolongs the lifetime of furniture, fabrics, and objects as damage caused by sun exposure is reduced. For instance, museums are leveraging smart-glass sunroofs that transmit bright, natural light ideal for viewing artwork while eliminating glare and harmful UV rays.

In addition to exterior windows and doors, smart glass can also be fitted on internal doors and partitions to offer increased levels of privacy and help instantly remodel a space while taking up a much smaller footprint than walls.

Example of progressively darker tint on architectural glass that uses electrochromic technology. (Image © Halio)

Across the transportation industry, a number of aerospace, automotive, and marine manufacturers have quickly started to integrate smart glass into the latest planes, boats, and vehicles.

Adjustable-tint windshields can adapt automatically to ambient light conditions to enhance visibility and increase safety. Heat-blocking windows and sunroofs limit the need for air conditioning and its components, reducing emissions and fuel consumption.

Electrical vehicle (EV) manufacturers are drawn to the allure of smart glass: “Tests show that SPD-SmartGlass can reduce fuel consumption and increase the driving range of electric vehicles by up to 5.5%, reduce CO2 emissions by 4 grams/km, block 95% of heat, and reduce the temperature inside vehicles by up to 18 ºF/10 ºC.”2

Electrochromic glass from Gentex is used in the Boeing 777 to block sunlight and heat, allowing passengers to selectively dim their windows. (Image © Gentex)

Smart glass is also finding new applications as a display technology. Unlike conventional displays where a glass screen sits in front of a panel that projects digital images (such as an LCD), some forms of smart glass can produce a display image from within the glass layers while maintaining a transparent quality.

For instance, a number of automakers are actively developing passenger windows that can act as touchscreen infotainment displays, and retailers are investing in store windows that act as a versatile marketing panel.

With a large number of current and potential uses for smart glass, it is predicted that the market will grow to almost $16 billion globally by 2027, a 17.2% CAGR,3 with the architectural and automotive market segments charting the course.

Gauzy LCG® - Smart & Interactive Advertising for Retail Stores

Demonstration of a smart retail window that can display promotional messages and videos, or return to a transparent state, all to draw in more shoppers. Video Credit: Gauzy

How Does Smart Glass Work?

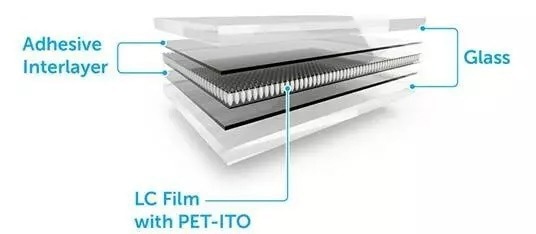

In essence, smart glass is manufactured with specific functional or “active” interlayers like films, liquid crystals, and electronics that are interspersed between two outer layers of glass.

This composition may also be made up of adhesive layers, laminates, spacing, and coatings. Various kinds of active layers or layer combinations offer a broad range of capabilities, enabling smart glass to serve a wide array of functions.

An example of smart glass consisting of an active layer (liquid crystal film) and adhesives sandwiched between two thin outer layers of glass. (Image © Gauzy)

Types of Smart Glass

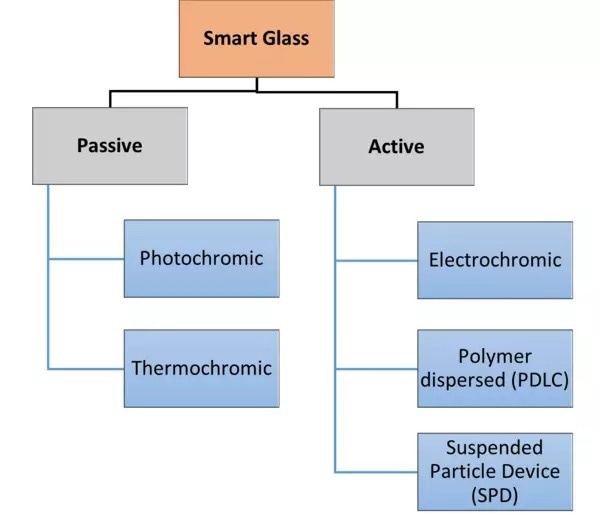

Smart glass technologies can be divided into two categories — passive and active. In passive technologies, the functional layer may be light-sensitive (photochromic) or heat-sensitive (thermochromic).

They are referred to as passive due to the fact they detect and respond to changes in the sun’s UV rays or radiant heat automatically. There is no need for an electrical charge, but modifications to tint or opacity cannot be controlled by the user.

Comparatively, active smart glass technologies are responsive to electric current thanks to a conductive layer that allows control of functions by the user. Electrified smart glass offers extra capabilities such as acting as a display screen, emitting light, enabling variable settings or patterns across a glass panel, or even accumulating solar power.

Active technologies are categorized as electrochromic, polymer dispersed liquid crystal (PDLC), and suspended particle device (SPD).

The smart glass category includes both passive and active technologies. Image Credit: Radiant Vision Systems

Photochromic Glass: Photochromic smart glass (the technology typically used for Transitions® eyewear) utilizes a layer of film with photo-sensitive molecules fixed to the inner or outer surface of the glass.

The molecules remain invisible until exposed to UV rays, which initiates a reaction (change in structure) and causes them to change transmittance (adjusts the amount of light passing through), going from clear to darker.

The degree of tint depends on the amount of UV — the glass adapts to a variety of light conditions. When UV is gone, the glass returns to its transparent state.

Thermochromic Glass: Thermochromic smart glass is fabricated with an interlayer of polyvinyl butyral (PVB) placed between glass layers. When the glass is hit by sunlight or radiant heat, it progressively darkens as the temperature rises.

Different materials, such as ceramic coatings, can be layered on the glass’s inner surface, which is able to trap the heat within the thermochromic layer, keeping temperatures cool inside a building or vehicle. As an additional benefit, these layers can also prevent noise.

Thermochromic glass in production with a PVB layer sandwiched between two glass layers. (Image © Sekisui)

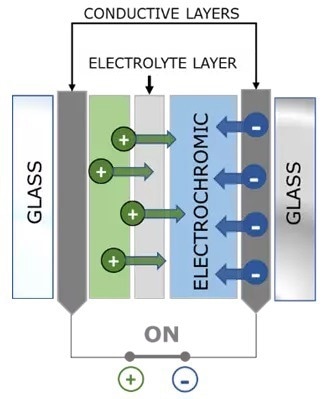

Electrochromic Glass: The color of electrochromic materials changes when an electrical current is applied. For this sort of smart glass, an electrochromic layer is placed between glass and conducting layers. Ions in an electrolyte layer are activated when a charge is applied, which causes the electrochromic layer to change from dark (or opaque) to transparent.

Schematic of electrochromic smart glass structure. Image Credit: Radiant Vision Systems

The glass remains clear on its own; electric power can be applied to change it back again. Previously, transitions from clear to opaque had been slow, but recent progress in manufacturing has seen a reduction in the switching phase to just two seconds. Electrochromic glass also possesses noise-blocking properties.

Electrochromic switchable partition in an office. (Image Source).

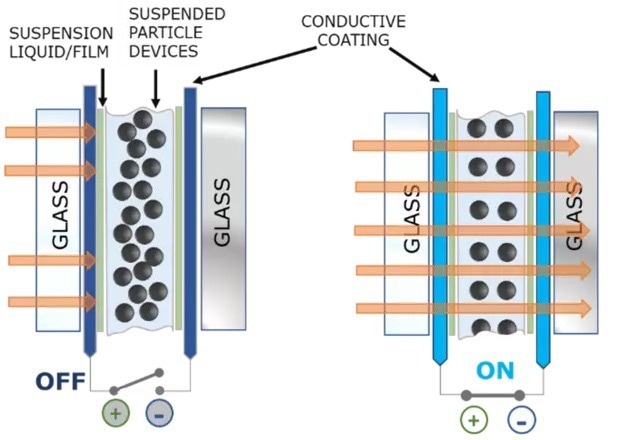

Suspended Particle Device (SPD): SPD glass combines a layer of particles between two conductive layers. When activating the conductive layers with an electrical charge, the particles line up, enabling light to pass through. In its inactive (dark) state, SPD glass has the capacity to block up to 99% of light.

Schematic of suspended particle device (SPD) smart glass, in the off and on states. Image Credit: Radiant Vision Systems

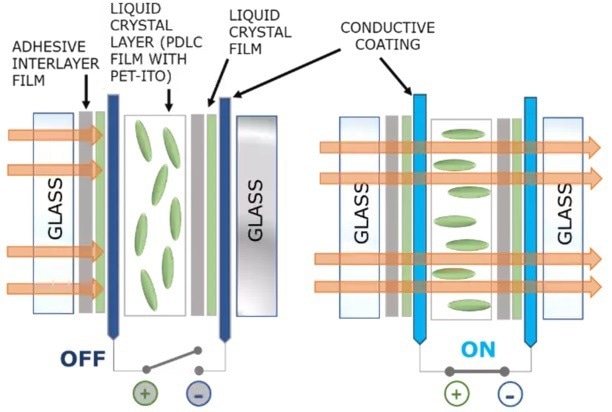

Polymer Dispersed Liquid Crystal (PDLC): PDLC technology utilizes a layer of LCD crystals fixed between conductive layers. Like electrochromic and SPD glass, its default off setting is opaque. With the application of an electric current, the crystals coordinate in parallel, making the glass transparent to allow light to pass through.

Schematic of Polymer Dispersed Liquid Crystal (PDLC) smart glass, in the off and on states. Image Credit: Radiant Vision Systems

Quality Considerations for Smart Glass Applications

Manufacturers of smart glass and the products that use it must take several factors into consideration to ensure good quality. The first is the quality of the formation and composition of the glass itself. Glass manufacturers must keep an eye out for a range of quality issues, including:

- Optical faults – Faults in the glass structure that may cause problems such as warping, or image distortion (when used for displays)

- Spot faults – Including bubbles and deposits within the glass

- Linear or extended faults – Scuffs or scratches on the surface layer

- Lamination defects – When sheets of glass are laminated with a variety of functional and electrical layers, adhesives and films, dust particles may get caught between layers or bubbles may form, which can impede the visual quality of the glass.

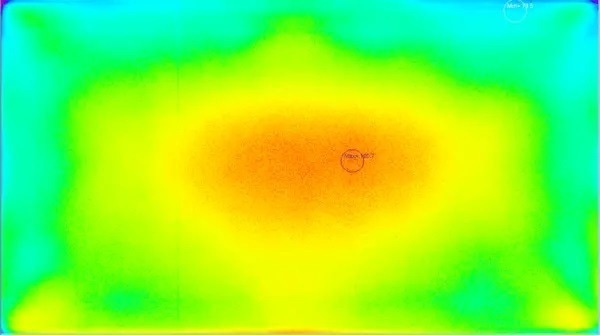

Key considerations to bear in mind for adjustable-tint and adjustable-opacity smart glass are uniformity in appearance and transmittance (the amount of light allowed to pass through).

Transitions between transmittance levels (for instance, from clear to dark) should appear even and consistent. Manufacturers need to establish if tint or opacity appears the same across the whole glass sheet, if the right amount of light passes through or is blocked, and if the tint is the correct color.

In this measurement image (shown in false color scale), light differences are evident in the center and along the bottom and corners of this panel, indicating poor uniformity. Image Credit: Radiant’s TrueTest™ Software.

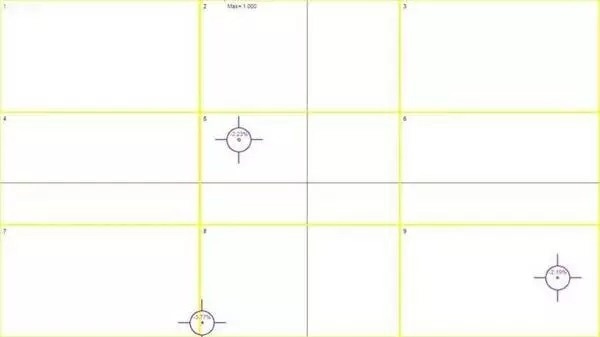

When using smart glass for displays, there are additional quality considerations that need to be added to the list, including clarity, luminance, shape, and orientation of virtual images, as well as their contrast or visibility in the ambient environment as visible through the glass surface.

For many smart glass display applications, image elements can be under a millimeter in size, so these must be measured precisely and accurately. For displays, curved glass generates an additional challenge for precise optical measurement.

Optical Measurement Solutions

Optical measurement systems can be applied to quantify the visual properties of glass, including values of light, such as chromaticity, luminance, uniformity, and contrast for the detection of the transmittance of glass at different stages of opacity.

Light values can also be applied to establish the sharpness or MTF (modulation transfer function) of illuminated regions like icons on a display or to establish where hot spots and dark spots lie across tinted or illuminated glass.

Detecting particles and lines in films or layers, assessing the completeness of display symbols and shapes, and determining the glass effects such as image distortion, warping, and ghosting — all require a spatial understanding of the glass’s visual qualities.

A smart glass test system must have the capacity to measure values and identify elements — and measure them in their true spatial positions.

Random defects identified on a panel using TrueTest™ Software. Image Credit: Radiant Vision Systems

For this, an imaging photometer or colorimeter is required to capture high-resolution data for accurate, detailed analysis and to measure the complete values of luminance and chromaticity. Just as important is the image processing and analysis software, which should provide specific algorithms for measuring these values and evaluating glass characteristics.

Radiant’s ProMetric® Imaging Photometers and Colorimeters have the ability to capture a complete field of view of the measurement area to effectively characterize all key criteria in the glass at once.

Specialized optical filters and calibrations make sure that light is weighted against standard CIE functions detailing the human visual response. This way, smart glass is assessed according to its brightness, color, and quality as observed by building inhabitants, vehicle occupants, display viewers, and device users.

A ProMetric Imaging Colorimeter (left) and Photometer (right) engineered to simulate human visual perception of light and color. Image Credit: Radiant Vision Systems

References

- Mann, T., “Humankind’s Most Important Material,” The Atlantic, April 7, 2018.

- “Two New Uses for Research Frontiers’ SPD-SmartGlass Technology Produced by Gauzy Lt. Unveiled at the IAA Munich Auto Show This Week. Research Frontiers, September 8, 2021.

- Smart Glass Market Size, Share…Forecast, 2020-2027, Fortune Business Insights, September 2020.

This information has been sourced, reviewed and adapted from materials provided by Radiant Vision Systems.

For more information on this source, please visit Radiant Vision Systems.