Sponsored by Element SixReviewed by Emily MageeJul 29 2024

A groundbreaking fiber-coupled diamond magnetometer has been possible by Element Six’s high purity CVD diamond and is set to advance structural material aging and medical diagnostics.

A group of researchers from the University of Warwick in UK has developed the most sensitive fiber-coupled diamond magnetometer in the world, driven by synthetic diamond unique properties, by leveraging a long-standing research partnership with world-leading synthetic diamond producer Element Six. The device measures the magnetic fields of objects or materials and analyses them using diamond nitrogen-vacancy (NV) centers’ quantum technology.

Image Credit: Element Six

This technology is enabled by Element Six’s engineered NV diamond materials, allowing the device to be precisely aimed toward a range of applications.

These applications can now also be investigated without cryogenic cooling since one of diamond's unique abilities is to operate at room temperature. This also facilitates miniaturization, meaning the devices developed can then be more easily converted into portable products.

The creation of sophisticated quantum-enabled healthcare solutions that could make early heart disease diagnosis feasible is made possible by diamond's remarkable properties, which are also perfect for medical diagnostic procedures like magnetocardiography (MCG). MCG quantifies the magnetic fields generated by electrical currents in the heart.

The Opportunity

Revolutionizing the Ease of Detection

Many applications, including mobile phones and automobiles sensors, employ magnetometry extensively. However, to get the highest sensitivity, the sensors are frequently big, expensive, and necessitate cryogenic cooling, which has a detrimental effect on usability. The latest diamond-enabled device is a compact, portable, tabletop option.

This innovative technology offers a much less intrusive piece of equipment than some conventional magnetometers while also having the ability to significantly reduce the cost per unit.

The user can also direct the diamond sensor at particular targets, up to 10 meters away, thanks to the fiber-optic wire. Such adaptability and portability are essential for improving heart disease detection, the most significant cause of death around the globe.

If scaled for mass manufacturing, this magnetometer could help medical practitioners identify heart conditions more quickly and precisely at the point of treatment, resulting in faster patient discharges and improved outcomes.

The hand-held and portable nature of the device allows for easy targeting and movement of the detection range in addition to biomedical uses. Due to this, this solution is also suited for heavy industry applications, such as analysing vast amounts of material for flaws or corrosion.

Although steel makes up the lion’s share of the greater part of the world’s metal production, it is subject to being corroded. The novel magnetometer technology here presented may make it easier for operators to analyse steel in situ for corrosion before costly or even fatal accidents occur, resulting in increased safety and cost-effectiveness.

The Challenge

Obtaining Sensitivity

Sensitivity is essential for magnetocardiography and high-value procedures, such as identifying corrosion in steel. The magnetometer’s goal is to quantify minute magnetic fields that are emitted from the heart or that are present on the surfaces of objects that could be corroded.

An ideal way to include room temperature operation into a small systems is to opt for diamond-enabled magnetometry.

Element Six’s world-first engineered quantum diamond grades are designed to have the perfect concentration of NV center defects while limiting the occurrence of other defects, to provide optimal sensitivity.

Finding the specific balance is difficult since the device’s accuracy is lowered by magnetic noise caused by potential impurities.

The Morley group based at Warwick relied on Element Six to provide custom-made, high-quality synthetic diamond so that additional parameters which could influence sensitivity, such as surface finish, would meet the stringent requirements.

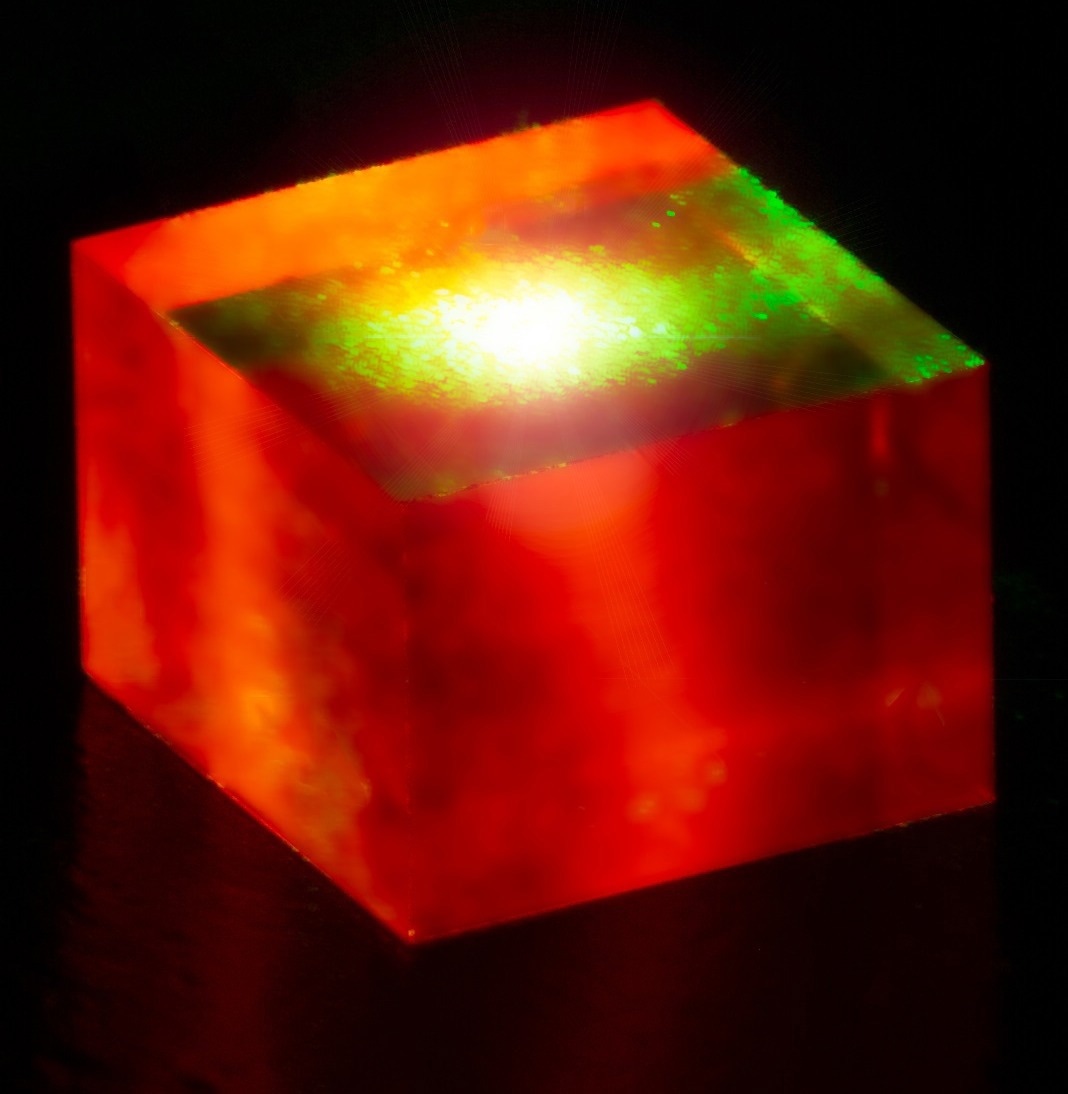

Element Six award-winning DNVTMB1. Image Credit: Element Six

The University of Warwick and Element Six’s Solution

High-Quality Diamond Magnetometry

Through decades of partnership and shared successes, Element Six has collaborated with the University of Warwick to move steps toward better accuracy and sensitivity in diamond-enabled quantum technologies.

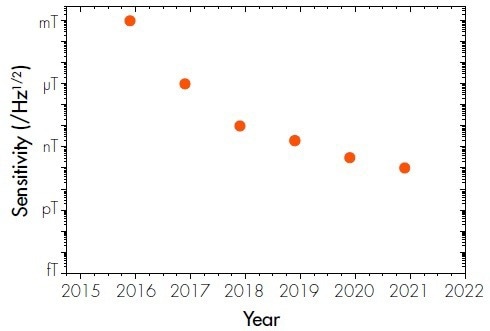

The magnetometer’s sensitivity has increased over five years of research projects by a factor of 10 million, moving from a milli- to nano-tesla threshold (as shown in the graph below), making the technology appropriate for uses such as the initial diagnosis of heart disease and the identification of steel corrosion.

The fiber-coupled diamond magnetometer at the University of Warwick has been improved in sensitivity by a factor of 10 million in five years. Image Credit: Element Six

Witnessing the sensitivity gains achieved by the immensely talented team at Warwick in such a short period has been great. It’s a testament to their knowledge of the field and practical expertise. We’re delighted to have made a significant contribution to this innovation and we look forward to seeing our diamond materials unlocking new milestones in the journey to commercializing quantum technology.

Dr Matthew Markham, Head of Quantum Technologies, Element Six

The UK Quantum Program, which has invested significant research funds to increase the product’s performance so far, has also been essential to the project’s success.

Members of the group at the University of Warwick who collaborated on the research received funding from the Networked Quantum Information Technologies Hub (NQIT), the Royal Society, and the Centre for Doctoral Training (CDT) in Diamond Sciences and Technology, which is supported by Element Six.

There’s no doubt that the quality of the diamond and the people I’ve been lucky enough to work with have been vital. They are the two most important factors in our success.

Dr Gavin Morley, Associate Professor, University of Warwick

Next Steps

The Morley group’s tool can detect corrosion in steel and may soon be able to measure a heartbeat pulse. The next task will be to turn this innovative approach into a marketable reality. In the future, Dr Morley hopes to scale the product down to make it more transportable and compact enough to fit in a backpack.

The Warwick team is also thinking about magnetoencephalography (MEG), which detects signals from the brain, as a potential future application. Although diamond MEG is more difficult since the magnetic fields from the brain are less than those from the heart, it may someday be utilised to diagnose conditions like schizophrenia and early-stage Alzheimer’s disease.

For our device to work, we need the diamond to be just right. Element Six has been the ideal development partner as the team has encouraged the kind of close cooperation that gets us to the position that we are currently in. They have manufactured exactly what we were looking for: a diamond that has the right shape, size, and spin properties.

Dr Gavin Morley, Associate Professor, University of Warwick

Why Diamond?

The prospect for extremely sensitive sensors to assess magnetic and electric fields is enormous, given the extraordinary fragility of quantum states. Due to its minimal background noise, the diamond crystal lattice is the ideal host material for solid-state qubits. Nevertheless, this fragility also makes it challenging to design processes.

Quantum states should ideally be separated from their surroundings, yet measurement necessitates some level of external interaction. The narrow line quantum engineers are increasingly motivated to cross to fully use this intriguing technology is the mix between control and interaction.

Element Six works together with its global academic network, including the University of Warwick, to scale this cutting-edge technology to practical, real-world solutions, offering unmatched synthetic diamond expertise and award-winning solutions.

What is a Diamond Nitrogen-Vacancy (NV) Center?

Pioneering research conducted in the 1990s and the early 2000s showed that a diamond defect, known as the nitrogen-vacancy center, has a quantum spin that can be controlled and read out at room temperature using standard optical methods.

The chemical vapour deposition (CVD) approach is used to grow a synthetic diamond, enabling the highly precise introduction of these engineered defects into the material.

When two nearby carbon atoms in the diamond lattice are removed, one of them is swapped out for a nitrogen atom, leaving the other one vacant and generating an NV center. The NV defect offers the ideal answer for extremely precise magnetometry since it contains an electronic spin extremely sensitive to magnetic fields.

What is truly remarkable is that, by simple shining a green laser on the material, you can measure the related spin by reading out the intensity of the resultant red fluorescence. At room temperature, it has been shown that NV electron spins can retain quantum information for more than 1 millisecond.

Although ensembles of several NV centers are necessary for particular applications, this read out of sensing and alignment can also be used for a single NV center, creating the potential for new levles of spatial resolution and nanoscale sensitivity.

Further Reading

- The diamond quantum revolution - M Markham & DJ Twitchen, 2020, PhysicsWorld

- Characterization of CVD diamond with high concentrations of nitrogen for magnetic-field sensing applications - AM Edmonds et al, 2021, Materials for Quantum Technology 1, 025001

- Imaging damage in steel using a diamond magnetometer - LQ Zhou et al, 2021, Physical Review Applied 15, 024015

- Sub-nanotesla magnetometry with a fiber-coupled diamond sensor - RL Patel et al, 2020 Physical Review Applied 14, 044058

This information has been sourced, reviewed and adapted from materials provided by Element Six.

For more information on this source, please visit Element Six.