In this interview, Carver explains how to choose the right press for your application.

How are hydraulic presses used in laboratories?

Many laboratory applications require pressure or heat to conduct various experiments. This includes compressing powders into mixtures for XRF analysis or pharmaceutical development, molding plastic or rubber material into samples for ASTM testing, analyzing the durability and strength of materials, along with prototyping and research and development projects.

What was the first documented use of a hydraulic press in a lab?

Carver first developed presses in 1912, originally for use in the cocoa industry. They have been optimized over the years to be ideal for many different applications and have become the international industry standard laboratory press. Carver presses can now be found in laboratories and prestigious Universities around the world.

Can you describe how these products have changed over the last 100 years?

Carver laboratory presses have improved design and functionality over the last 100 years. Carver still offers the original hand operated Model C press but also incorporate programmable controls in our AutoSeries line of automated presses. Carver can add automation and heating capabilities to existing manual presses and offers options to improve temperature uniformity and platen parallelism. All new presses are manufactured with OSHA and ANSI compliant guarding to protect the operator.

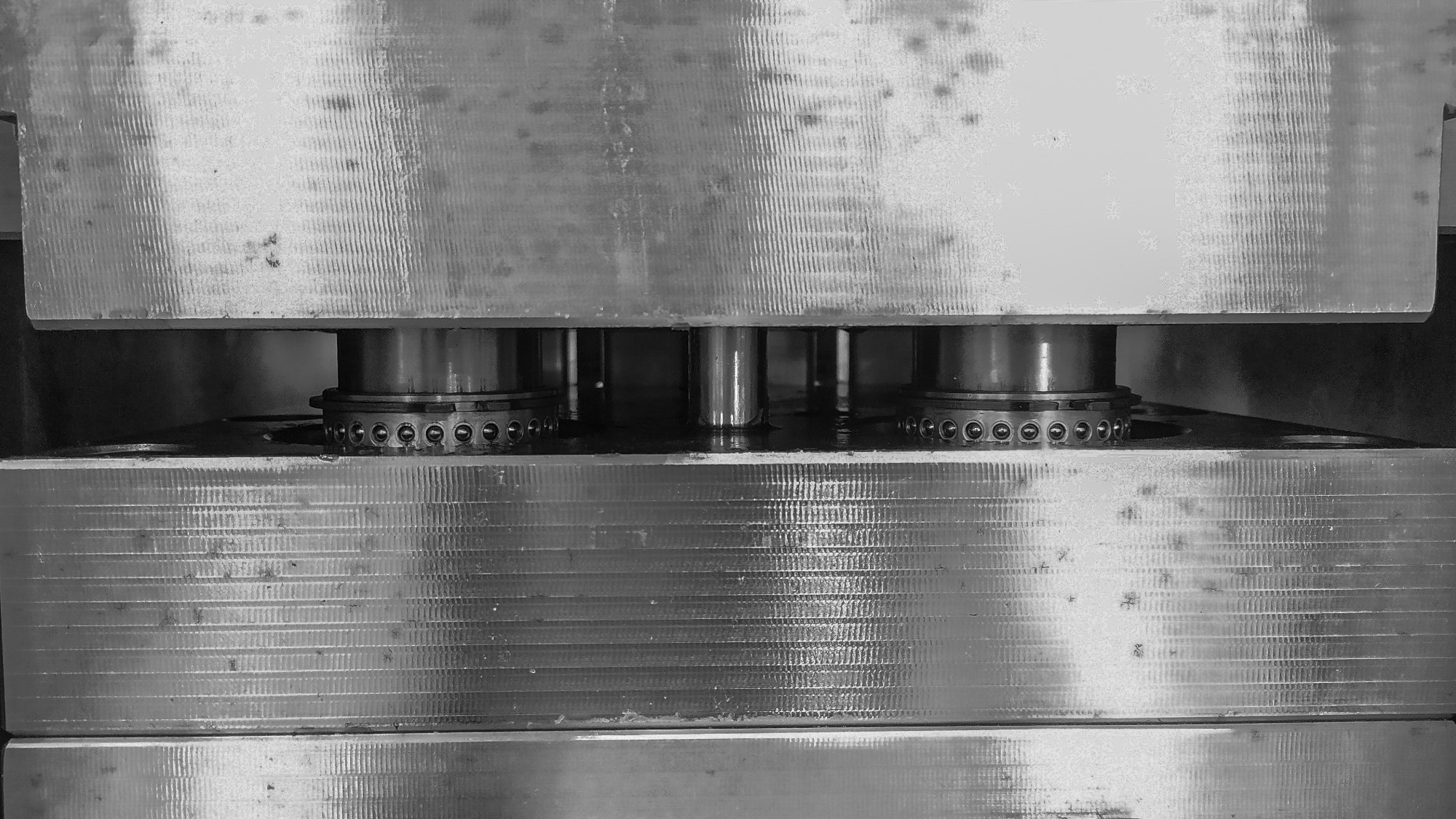

Image Credit: Lorenzo_Olympus/Shutterstock

Image Credit: Lorenzo_Olympus/Shutterstock

Can you describe the range of hydraulic presses offered by Carver?

Carver offers many different styles of presses that would be ideal for your application. A standard selection of manual hand operated benchtop presses with clamp forces up to 30 tons are available, as well as the AutoSeries line of programmable presses with user-friendly controls and clamp forces up to 48 tons.

Carver also offers the Monarch series floor standing industrial press with clamp forces up to 100 tons and capable of production use.

What is the difference between general and specialized hydraulic presses?

Standard presses like the Model C or Auto C can be used in general applications like pelletizing, pressing printed circuit boards, and destructive testing. Carver also manufactures specialized presses for ASTM polyethylene, polypropylene, and elastomer testing as well as a proppant crush press compatible with ISO 13503-2:2006 for the fracing industry.

Why must lab managers and researchers choose the right hydraulic press?

Every application will have unique requirements for clamping force, dwelling time, temperature, and several other factors that are necessary to the creation of a successful sample. Therefore, it is critical to select the press most suited for the specific application to achieve the best possible results.

Image Credit: QinJin/Shutterstock

Image Credit: QinJin/Shutterstock

How does Carver’s extensive experience in the field make this choice easier?

Carver can help make selecting the appropriate press an easy decision for you. With your application requirements, our sales team and engineers can use our extensive experience to provide a standard press or provide a custom option to fit your unique needs.

What do Carver products offer labs that competitors may not?

Carver laboratory presses are manufactured to be highly precise and durable. A heavy-duty hydraulic system, iron bolsters, and high tensile steel tie rods will guarantee many years of service using a Carver press.

Threaded rods with nuts allow for rapid and precise platen adjustment, and heated platens with accurate digital control can be integrated into manual and automated presses.

What level of customization can Carver offer?

Carver is proud to have a dedicated engineering team that can integrate customized options into our presses and develop equipment compatible to ASTM and other laboratory testing. Carver understands that every application can be unique and will strive to meet your press needs.

What challenges will labs face in the future, and how can Carver press help them meet these obstacles?

Laboratories will continuously face new challenges as technology evolves, and Carver can help you keep up with the latest requirements, certifications, and trends in equipment. From improving precision to collecting data, Carver is dedicated to providing the tools needed to succeed today and in the future.

About Donovan Sparks

Regional Sales Manager with over 10 years of experience providing solutions to residential, business, and international markets. Approachable sales professional who strives to secure new business and retain long term relationships with accounts.

I am actively involved with developing marketing and sales plans to engage prospects and promote revenue growth, and network at conventions in medical, research, and laboratory industries to generate new opportunities. I have a wide range of sales experience in retail management as well as business sales to domestic and international clients. Professionalism is my priority as I guide you through the investment process and ensure after sales support for the life of your equipment.

This information has been sourced, reviewed and adapted from materials provided by Carver, Inc.

For more information on this source, please visit Carver, Inc.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.