Sponsored by WITec GmbHReviewed by Maria OsipovaOct 16 2023

Raman imaging microscopy is well on its way to completing its evolution from specialized tool to standard analytical technique. This progression can be seen in the steady increase in the overall number of fields that employ it and the range of its applications within those disciplines.

Developments in experimental flexibility and user-friendliness have accelerated the trend in recent years.

During the 1970s and 80s, chemical characterization with Raman spectroscopy became a viable option as commercial solid-state photonics devices were made available. Lasers provided stable, monochromatic light sources across a range of wavelengths for sample excitation. Charge-coupled devices offered the sensitivity to detect signals from weak Raman scatterers and to acquire large numbers of spectra very quickly.

Though employed primarily by those familiar with spectroscopy, such as physicists, chemists and materials scientists, these technologies enabled the first wave of adoption of Raman-based analysis.

Throughout the 1990s, personal computers became more powerful, and precise piezo-driven sample scan stages made it possible for Raman instruments to record an entire spectrum at each measurement point and compile them to generate an image.

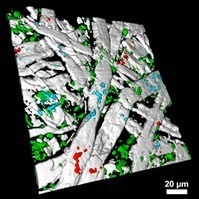

Raman imaging microscopy was introduced to the marketplace by WITec GmbH in 1999. Once scientists saw high-resolution visualizations of sample component distributions in three-dimensions (as displayed in Figure 1), demand for the nondestructive, label-free technique rapidly expanded.

Figure 1. 3D Raman image of paper with surface additives. Image Credit: WITec GmbH

Today the application of Raman imaging extends far beyond its early user base, finding utility in fields as diverse as archaeology, quantum device research, forensics, pharmaceutical development, environmental science and many others.

High-resolution Raman imaging experiments require a multitude of components working in harmony to extract as much information as possible from each measurement. This had at times been intimidating for users new to the technique.

However, the introduction of innovative control software and motorized optical elements has made even the most complex investigations readily accessible.

It is now possible to configure an experimental workflow via graphical user interface, and each instrument setting can be stored along with the acquired data. Automated components eliminate the need for manual adjustment and calibration while ensuring results remain reproducible, while also reducing potential sources of error.

With the advent of automated Raman imaging microscopes (Figure 2), the full analytical power of Raman imaging is now widely utilized by researchers from university groups and multi-user facilities to industrial quality control teams.

Figure 2. Automated Raman imaging system WITec alpha300 apyron. Image Credit: WITec GmbH

The future of Raman microscopy will see its further integration with complementary techniques and controlled sample environments.

In recent years, state-of-the-art modular Raman microscopes have been incorporated into scanning electron microscopes (SEMs). The leading instruments are WITec’s Raman Imaging and Scanning Electron (RISE) microscopes (Figure 3), which featrue a common vacuum chamber and can also incorporate energy-dispersive X-Ray spectroscopy (EDS).

Figure 3. RISE Microscopes: Fully-integrated Raman Imaging and Scanning Electron Microscopy. Image Credit: WITec GmbH

Cutting-edge methods such as second- and third-harmonic generation (SHG, THG) have now joined the list Raman imaging options and are especially useful for investigating low-dimensional materials, including transition metal dichalcogenides (TMDs).

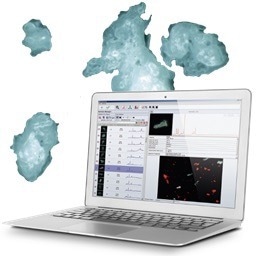

Microparticle investigations are another flourishing application of Raman-based analysis. Sophisticated algorithms produce a map of microparticle locations from a white-light image, even over large areas. This map then guides the measurement to obtain a Raman spectrum from each particle for chemical identification, a process that can be expedited by using Raman spectral database software.

Tools that incorporate these elements, such as WITec’s ParticleScout (Figure 4), are extremely valuable when analyzing microplastic pollution in environmental samples.

Figure 4. ParticleScout is an advanced tool for Raman-based particle analysis. Image Credit: WITec GmbH

Modular Raman microscopes can also be configured for experiments conducted in cryogenic chambers. Cryogenic Raman microscopy can reveal properties of exotic materials that exhibit quantum effects near absolute zero.

Fully automated and modular Raman instruments can be installed in glove boxes and other environmental enclosures for the analysis of hazardous samples or those manufactured with processes such as chemical vapor deposition.

These are just a few of the Raman microscopy variations in use at the moment. Given the pace of recent developments, many further innovations can be expected as the scientific community requires new tools to meet emerging challenges.

Raman spectroscopy has evolved from a Nobel Prize-winning experiment into an expert’s choice for chemical characterization, to an accessible sample component visualization method, and is now set to become a standard analytical technique in laboratories across the full spectrum of research applications.

This information has been sourced, reviewed and adapted from materials provided by WITec GmbH.

For more information on this source, please visit WITec GmbH.