Potassium is an element necessary for the production of chemical fertilizers for agricultural use. The element is acquired through mining and extraction methods of potash. Canada is currently the world’s largest national producer and exporter of potash.

Image Credit: Strongwell Corporation

A major producer recently asked the ICON Industrial Group Ltd of potash in Canada to source a material that would be economical yet durable enough to endure exposure to an extremely corrosive environment within its potash operations.

With years of extensive composites experience, ICON’s recommendation was to incorporate and use Strongwell FRP (SAFPLATE®, DURAGRID®, EXTREN®, SAFRAIL™, and DURAGRATE®) within the customized designs of two structures within the debrining area of the potassium mining site.

Secondary Containment

Water and salt are required to effectively mine potash deep within the earth to dissolve the potash deposits. This highly corrosive liquid formulation is known as the brining solution. The liquid is then piped, treated, and recirculated.

In circumstances where potential pipe leakages may arise, it is necessary to protect structures underneath the piping outfit by installing a secondary containment system for mitigation of the corrosive properties of the brining solution.

In this design, the secondary containment system was installed to protect centrifuges, a crane, and the processing equipment underneath the vast piping network.

Before installation was initiated, checking and ensuring a good seal was necessary. Thus, the containment system was tested with 4 inches of standing water to prove a 100% seal across the entire floor elevation.

Inertia Platform

Previously, workers needed to tie themselves off while working around debrining centrifuges due to the elevated access points of the centrifuges.

To combat these safety concerns, inertia platforms were developed to offer access to a stable noncorrosive working surface for personnel working around the centrifuges. This removed the need for tethering while resulting in improved access to key equipment.

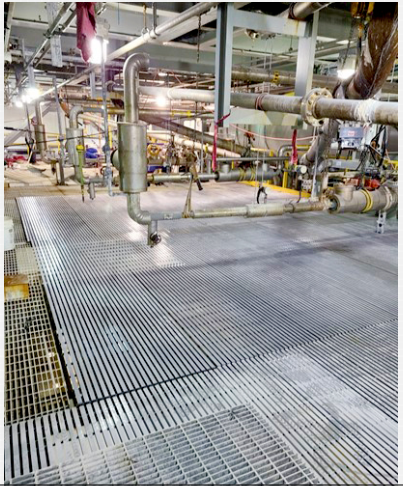

Containment System - Installing grating. Image Credit: Strongwell Corporation

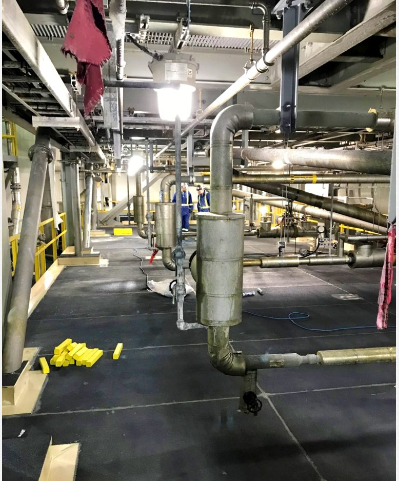

Containment System - Containment Install. Image Credit: Strongwell Corporation

Containment System - Containment Testing. Image Credit: Strongwell Corporation

Inertia Platform - Before. Image Credit: Strongwell Corporation

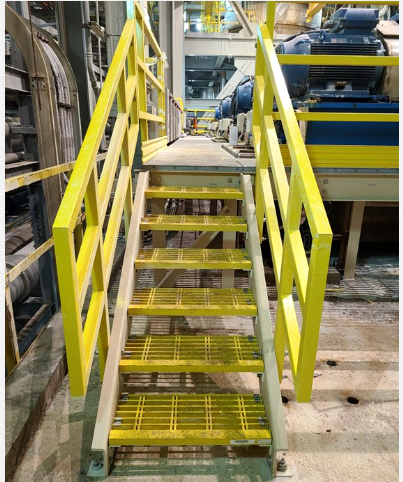

Inertia Platform - After. Image Credit: Strongwell Corporation

Project Savings

Upon delivery of the initial design, both ICON and the plant operator agreed that the EXTREN® Series 625 delivered an improved corrosion resistance rating compared to carbon steel. This eased the concerns related to corrosion maintenance costs during the project's life cycle.

Besides offering corrosion resistance, the lightweight nature of FRP generated cost-savings estimated between 30-50% relative to associated labor and additional equipment costs that may have been necessary if using carbon steel.

The majority of contributing factors for these savings were associated with the heavy weight of transporting, rigging and fabricating with steel.

After six months, ICON followed up with the end user to report that the secondary containment system showed no signs of leakage. Employees also provided positive feedback on how the inertia platforms improved accessibility, safety protocols, and production processes.

This information has been sourced, reviewed and adapted from materials provided by Strongwell Corporation.

For more information on this source, please visit Strongwell Corporation.