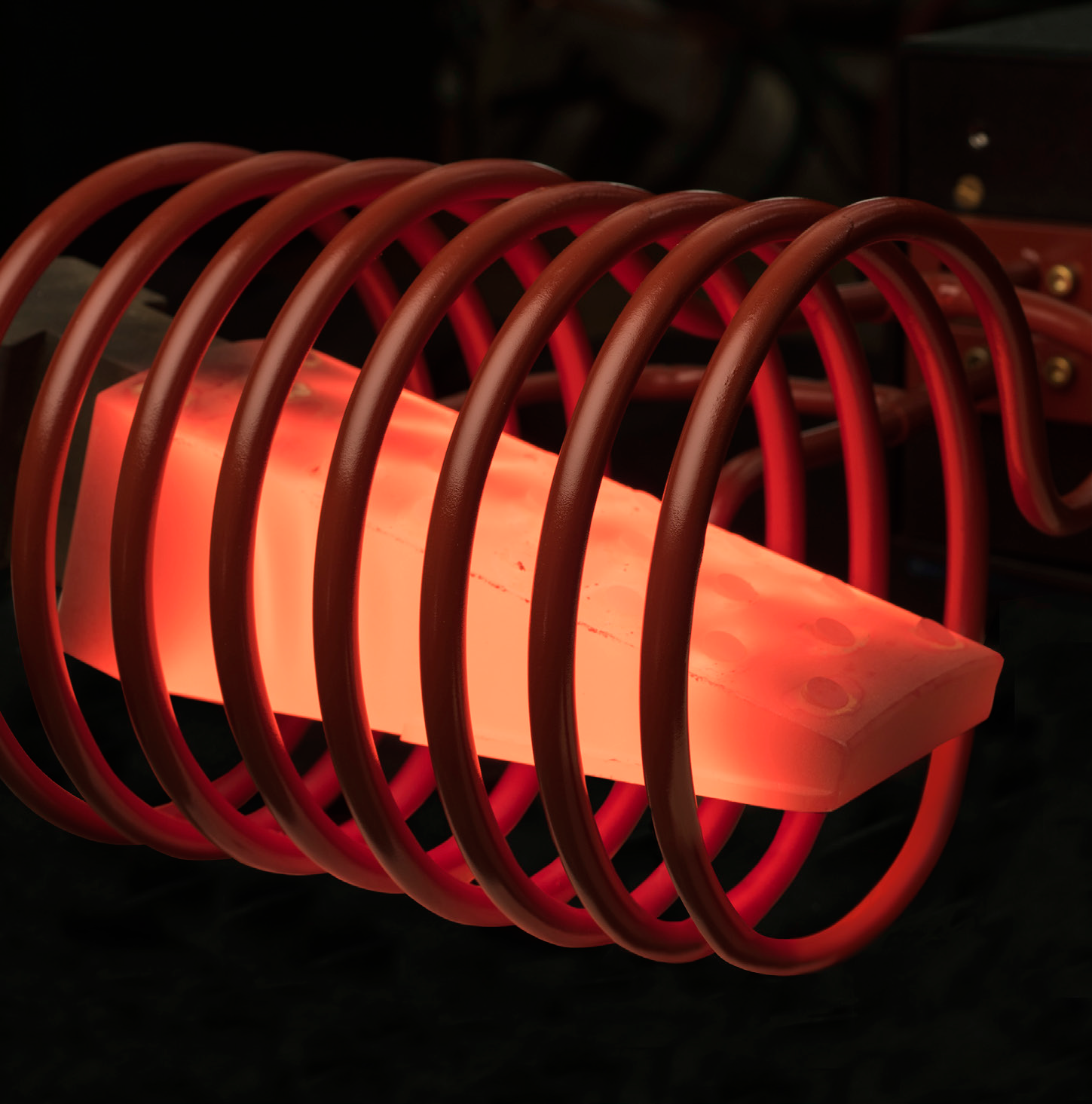

Induction heating is a non-contact method for the rapid, efficient, precise, and repeatable heating of metals or other electrically conductive materials. An induction heating system comprises a power supply that converts line power to an alternating current. This current is guided to a workhead and work coil, generating an electromagnetic field within the coil.

Image Credit: Ambrell Induction Heating Solutions

The work piece is placed in the coil where this field induces a current, generating heat in the work piece. The water-cooled coil is cool to the touch and is placed around or adjacent to the work piece. It does not touch the work piece, and heat is generated by the induced current flowing in the work piece.

The work piece can be made of metal such as steel, copper, aluminum, brass, or a semiconductor such as carbon, graphite, or silicon carbide. Non-conductive materials such as plastics or glass are heated inductively with the application of an electrically conductive susceptor, usually graphite.

While induction heating has been around for a while and is by no means a new concept, it is a green technology. It does not depend on fossil fuels, nor does it create any hazardous emissions or carbon dioxide (CO2).

In contrast to gas heating systems, induction offers a cleaner, safer, and more comfortable work environment. When compared to torch heating, induction is flameless, meaning less heat is introduced into the workplace.

Image Credit: Ambrell Induction Heating Solutions

What Makes Induction a Green Technology?

Induction heating is better for both employees and the environment. In addition to the environmental benefits, induction heating provides a series of benefits to employees and businesses, as it prevents smoke, waste heat, noxious emissions, and loud noise. Numerous emission-producing processes can be converted to induction heating, such as:

- Flame brazing

- Flame hardening

- Flame melting

- Flame preheating

- Flame shrink fitting

- Gas-fired oven heating

- Welding torches for joining

Image Credit: Ambrell Induction Heating Solutions

Image Credit: Ambrell Induction Heating Solutions

Induction Heating is a Safer Technology

Besides improving air quality, induction heating also offers many other key employee safety benefits, including:

- No Ultraviolet (UV) Exposure: Induction releases no UV into the environment, unlike flame heating. This prevents the risk of UV damage that can occur to the skin and eyes of employees from using flame heating sources. There are still safety requirements to consider with induction heating, such as employee training, personal protective equipment, proper installation, signage, and lockout procedures to help mitigate risk.

- Reduction in risk of contact burns: Since only a specific part of the work piece is heated via induction, there are limited hot areas, which reduces employee contact. As a result, the risk of contact burns is considerably reduced when compared to gas-heated oven or exhaust system exteriors.

- Zero explosive gases: Induction uses electricity as the energy source. This removes the need to handle high-pressure explosive gases. Typically these gases are transported in a hot, crowded environment, which increases the risk of catastrophic failure.

Induction Heating is More Efficient

Induction is an energy-efficient heating process that converts 70-90% of the consumed energy into useful heat. In contrast to electric ovens, which are typically only 45% energy efficient, the overall efficiency of induction heating is up to two times greater.

Moreover, gas oven efficiency is only around 25-30% energy efficient, which comparatively makes induction three times more efficient, especially considering that start-up and shutdown heat losses are eliminated as induction requires no warm-up or cool-down cycle.

The repeatability and consistency of the induction heating process make it highly compatible with energy-efficient automated systems.

Image Credit: Ambrell Induction Heating Solutions

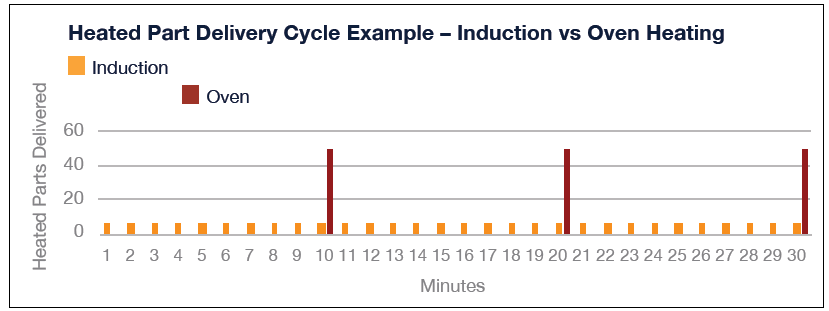

Induction Supplies More Consistent Output Than Oven Heating

Image Credit: Ambrell Induction Heating Solutions

The application of constant flow induction heating leads to a considerable efficiency improvement when compared to batch oven heating. Induction heating eliminates losses in both energy and time due to oven loading and unloading.

Delivering a consistent flow of parts, induction supports later key stages in the manufacturing process that require heated parts. This increases the overall efficiency of the cycle as the heat loss from the part is significantly reduced when it reaches the next step. These savings are not only achieved in production efficiency but also result in the better use of heating energy overall.

Image Credit: Ambrell Induction Heating Solutions

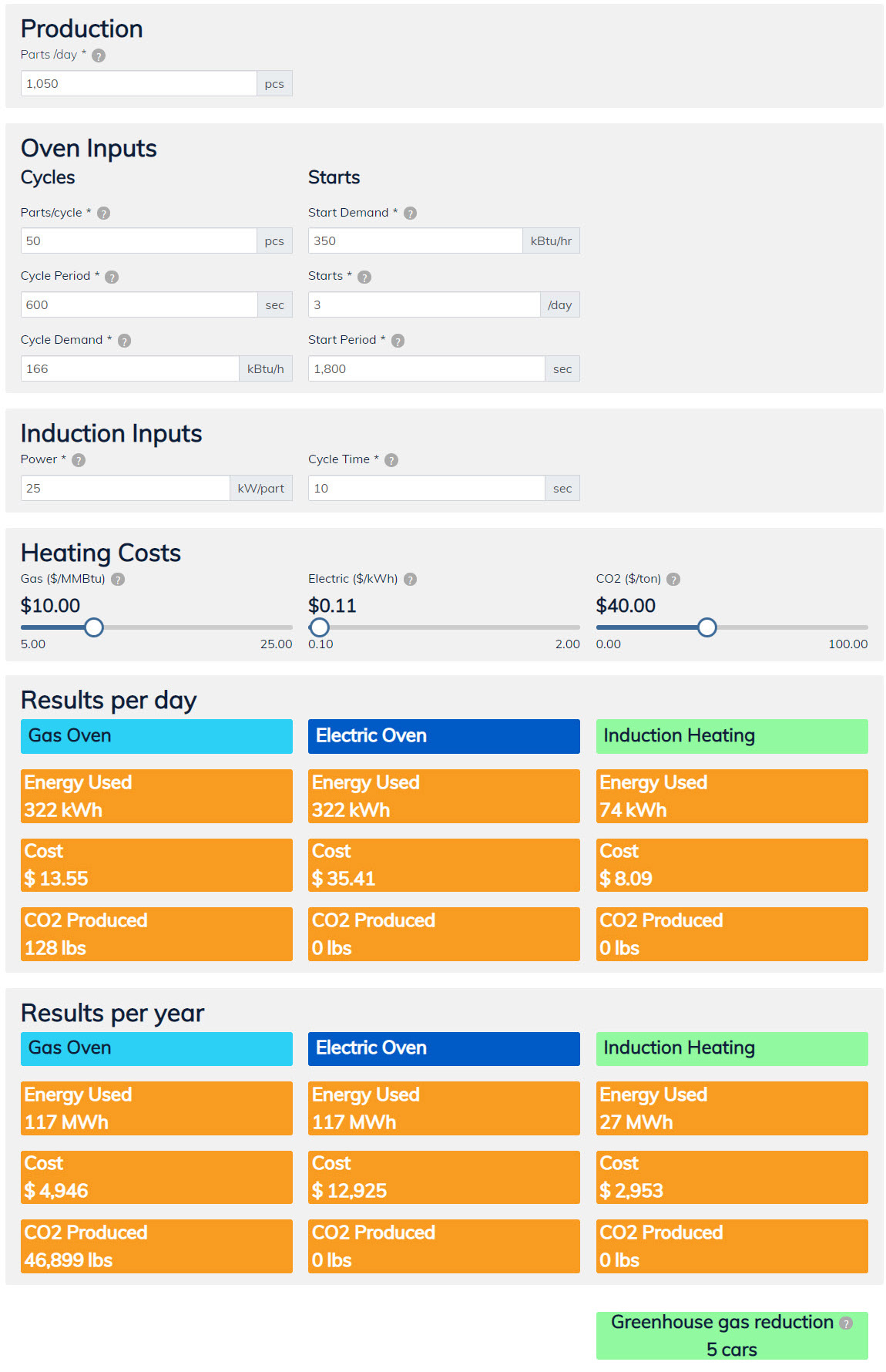

Induction Versus a Gas Oven is Cost Effective

When a client using an oven switches to induction, the environmental impact is considerable. Given the inputs shown in the image below, induction heating saves 128 pounds of CO2 per day and over 46,899 pounds on an annual basis. This is equivalent to taking five internal combustion engine cars off the street.

Image Credit: Ambrell Induction Heating Solutions

While induction heating offers considerable cost savings when compared to a gas oven, and the difference compared to an electric oven is usually even greater. The cost variables are contingent on local rates; therefore, it is advisable to use Ambrell’s Energy Calculator to apply the current rates relative to the location where induction is likely to be used.

Due to the direct transfer of energy to the work piece, induction heating wastes little heat resulting in significant energy savings.

Image Credit: Ambrell Induction Heating Solutions

Read the Rest of the Brochure Here

Read the Rest of the Brochure Here

This information has been sourced, reviewed and adapted from materials provided by Ambrell Induction Heating Solutions.

For more information on this source, please visit Ambrell Induction Heating Solutions.