As a result of the continuing climate crisis, there is a strong need to increase the energy efficiency of sophisticated material production processes. The production of classical cement is accountable for nearly 8% of global CO2 emissions, and clinker production accounts for the majority of such emissions. New technologies are being developed to decrease the carbon footprint of cement-like materials.

There are various methods in the development of decarbonized cement-like materials:

- Decrease the amount of clinker needed

- Clinker can be replaced with carbon-neutral materials

- Capture the CO2 needed for the process

In each of these methods, elaborate scientific analysis is needed throughout development and production. X-Ray diffraction (XRD) is a strong analytical method to determine crystalline components and measure them collectively with possible amorphous content.

Sophisticated analytical software provides options for a standardless method to measure the amorphous part of a mixture, which serves a considerable role in advanced cement-like materials.

Instrument

The Thermo Scientific™ ARL™ EQUINOX XRD Series constitutes a portfolio of XRD instruments that range from simple, user-friendly benchtop systems available for routine examinations to highly advanced floor-standing, research-grade systems.

The Thermo Scientific ARL EQUINOX 100 X-Ray Diffractometer applies a custom designed 50 W (Cu or Mo) or 15 W Co high-brilliance micro-focus tube with mirror optics that do not need an external water chiller.

The unit could be transported between laboratories or into the field in the absence of any special infrastructure.

The ARL EQUINOX 100 Diffractometer offers more rapid data collection than other diffractometers due to its special curved position-sensitive detector (CPS) that quantifies all diffraction peaks concurrently and in real time.

Figure 1. ARL EQUINOX 100 X-Ray Diffractometer. Image Credit: Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers

Experimental

Using an ARL EQUINOX 100 Diffractometer with Cu Kα radiation, powdered (ball-milled) samples were measured in reflection mode. Data evaluation (qualitative and quantitative) was executed utilizing the MDI JADE 2010 and ICDD PDF4+ database.

Using WPF Rietveld refinements, quantification was performed. A standardless method for quantification of amorphous content (utilizing pseudo-RiR values) was utilized.

Results

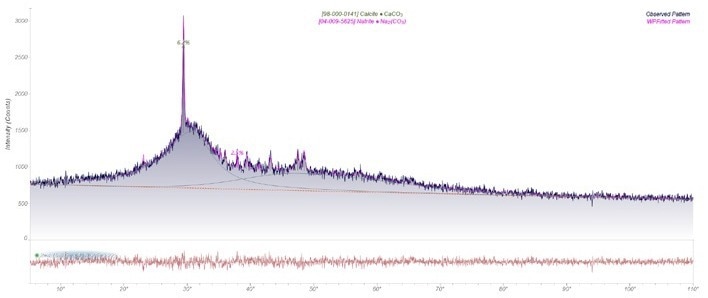

A novel method for decreasing the clinker content in cement uses a mixture of calcined clay and limestone collectively with clinker and gypsum. A sample of such a mixture was examined (Figure 2), comprising nearly 91% amorphous material (calcined clay), 3% natrite (Na2CO3), and 6% calcite (CaCO3),

Figure 2. XRD pattern of calcined clay and calcite sample. Image Credit: Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers

Figure 3 shows natural gypsum with a small quartz side phase.

Figure 3. XRD pattern of gypsum sample. Image Credit: Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers

Fly ash (Figure 4), an industrial waste product, could be utilized as a cement-like material to replace clinker entirely. Its quality strongly relies on the material’s amorphousness. The fly ash displayed in Figure 4 is nearly 100% amorphous with a slight quartz side phase.

Figure 4. XRD pattern of fly ash sample. Image Credit: Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers

Portlandite (Figure 5) could be added to the cement mixture and then cured with waste CO2, which considerably decreases the carbon footprint. A portlandite sample comprising 39% amorphous material, 5% calcite, 51% portlandite, 1% quartz, and 4% grossite is shown in Figure 5.

Figure 5. XRD pattern of portlandite sample. Image Credit: Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers

Conclusion

The ARL EQUINOX 100 X-Ray Diffractometer generates data that is ideally suited for examining decarbonized cement-like material samples. Measuring the amorphous content with the help of a standardless approach has proven to be a strong method that directly yields the composition of highly complicated mixtures.

This article was adapted from materials by Dr. Simon Welzmiller and Dr. Henry Pilliere at ThermoFisher Scientific.

This information has been sourced, reviewed and adapted from materials provided by Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers.

For more information on this source, please visit Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers.