.jpg) By Susha Cheriyedath, M.Sc.Feb 22 2023

By Susha Cheriyedath, M.Sc.Feb 22 2023Compound semiconductors are semiconductors that contain two or more elements. These semiconductor crystals can be grown with different lattice constants and bandgap energies that are suitable for developing novel optoelectronic and electronic devices. This article discusses compound semiconductors and their role in optimizing energy efficiency in devices.

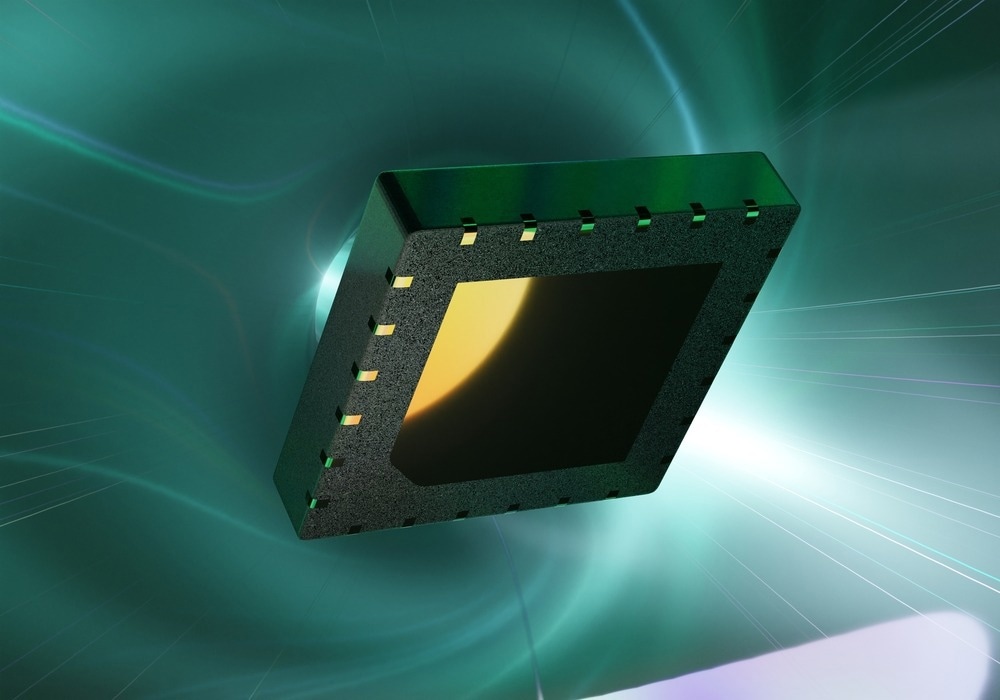

Image Credit: John Cummings/Shutterstock.com

The Importance of Compound Semiconductors

Most compound semiconductors contain elements from group III and group V of the periodic table. Gallium arsenide (GaAs), gallium phosphide (GaP), gallium nitride (GaN), indium arsenide (InAs), indium antimonide (InSb), indium nitride (InN), and indium phosphide (InP) are the common III-V compound semiconductors. InP and GaAs are primarily used in optical and high-frequency devices.

Other compound semiconductors, such as cadmium telluride (CdTe), cadmium selenide (CdSe), and zinc selenide (ZnSe), are typically composed of elements from group II and group VI. Additionally, different elements from the same group, such as group IV, can also be used to synthesize compound semiconductors such as silicon carbide (SiC) and silicon germanium (SiGe).

In commercial applications in the past, compound semiconductors were not used as extensively as silicon semiconductors, as growing these crystals was more difficult compared to silicon. Additionally, compound semiconductor manufacturing was expensive, and the crystals had a high number of defects. Compound semiconductors were also more fragile than single-element semiconductors.

However, the compound semiconductor manufacturing cost has reduced in recent years. Although the cost and complexity of compound semiconductor manufacturing are still higher than traditional silicon semiconductors, the fundamental material properties of compound semiconductors have made them crucial in several applications, specifically sensing and optoelectronic applications.

For instance, compound semiconductors play a critical role in optoelectronic devices used in solid-state lighting, high-density data storage, and photovoltaics due to their direct bandgap structure and the flexibility to synthesize band-gap engineered structures using several compound semiconductors.

Thus, compound semiconductors can be used to create quantum structures and heterostructures such as quantum dots (QDs) and quantum wells (QWs), which are used extensively in optoelectronic devices, including semiconductor optical amplifiers, modulators, photodetectors, and lasers. Other important applications of compound semiconductors include autonomous and electric vehicles, radio detection and ranging (RADAR), 5G, mobility, energy, and new business models.

The intrinsic properties of compound semiconductors, such as operation at high frequencies and temperature, higher electron saturation velocity, efficient emission and detection of light, variable thermal conductivity, piezoresistivity, piezoelectricity, and variation in the band gap, are the key advantages of these semiconductors over conventional silicon technology.

Micromotors, microbolometers, radio frequency inductors, waveguide switches, cantilevers, and wavelength-tunable microcavity devices such as photodiodes, light emitting diodes (LEDs), vertical-cavity surface-emitting lasers (VCSELs), optical amplifiers, and optical filters have been fabricated by micromachining compound semiconductors.

Compound semiconductors made using elements from group III and group V and elements only from group IV are used for microsystems due to their material properties. For instance, GaAs-based semiconductors were studied extensively to fabricate integrated sensors owing to their high piezoelectricity and superior thermoelectricity properties.

GaAs can meet the requirement for maximum thermal resistance as its thermal conductivity is significantly lower than that of silicon. Similarly, exceptional bolometric infrared sensors were synthesized using suspended aluminum gallium arsenide (AlGaAs) membranes due to their wide energy gap, high Seebeck coefficients, and piezoelectric properties.

GaAs-based materials were also used to fabricate self-assembled, strain-driven three-dimensional (3D) micro/nanostructures. InP-based materials are considered suitable for optical fiber communication system light sources owing to low dispersion and loss at 1.5 μm and 1.3 μm wavelengths.

Wider bandgap compound semiconductor materials, such as SiC and GaN, can be used feasibly for microelectromechanical systems (MEMS) applications in extreme environments. Poly-SiGe has been used to synthesize micromachined thermopiles and bolometers with superior thermoelectric properties.

Improving Energy Efficiency in Devices Using Compound Semiconductors

Increasing deployment of artificial intelligence (AI) and Internet of Things (IoT) applications and growing migration to the cloud have increased the need to improve energy efficiency in the energy-intensive IT infrastructure.

Compound semiconductors, specifically SiC, possess a higher energy efficiency than silicon semiconductors due to the significantly lower reverse charge and energy loss of SiC, which reduce the energy required during the switch-off and switch-on phase and more switching power.

The need for cooling systems is also eliminated due to lower heat loss, which decreases the weight and space of a device and reduces the infrastructure cost. Moreover, SiC can be used at high operating temperatures due to its wider bandwidth compared to pure silicon.

Compound semiconductors with a wider bandgap have a high electric breakdown field and a reduced susceptibility to radiation. The high thermal conductivity of SiC allows better dissipation of heat. Thus, form factors that are smaller than silicon can be realized using SiC, leading to smaller packaging and lower costs.

In SiC diodes, the current and temperature transients do not affect the recovery current and time, unlike in silicon diodes, where both recovery current and time increase significantly with the increasing temperature. Thus, SiC diodes can effectively reduce energy losses when placed in antiparallel to silicon insulated-gate bipolar transistors (IGBTs).

In practical applications such as hybrid electric vehicles, the replacement of silicon components with SiC components can increase the traction efficiency by 10%, which can substantially reduce the heat sink volume.

Similarly, faster, lighter, smaller, more reliable, and more energy-efficient power electronic components can be fabricated using wide bandgap compound semiconductors such as GaN and SiC in place of silicon.

To summarize, compound semiconductors will be used more extensively in the future owing to their superior material properties over silicon semiconductors and their role in optimizing the energy efficiency of devices.

More from AZoM: The Intersection Between AI and 3D Printing

References and Further Reading

Jagadish, C., Tan, H.H., Buda, M., Barik, S., Mokkapati, S., Fu, L. (2011). Disordering of Quantum Structures for Optoelectronic Device Integration. Comprehensive Semiconductor Science and Technology, 584-625. https://doi.org/10.1016/B978-0-44-453153-7.00004-3

Hillmer, H., Dharmarasu, N. (2008). Compound Semiconductors. Comprehensive Microsystems, 25-51. https://doi.org/10.1016/B978-044452190-3.00003-3

What is a Compound Semiconductor [Online] Available at https://www.csfusion.org/semiconductor/compound-semiconductor/ (Accessed on 06 February 2023)

Fryer, T. (2018) Compound semiconductors point the way ahead for life after silicon [Online] Available at https://eandt.theiet.org/content/articles/2018/09/compound-semiconductors-point-the-way-ahead-for-life-after-silicon/ (Accessed on 06 February 2023)

Compound Semiconductors [Online] Available at https://www.doitpoms.ac.uk/tlplib/semiconductors/compound.php (Accessed on 06 February 2023)

Emilio, M.D.P. (2020) The Importance of SiC Semiconductors for Energy Efficiency [Online] Available at https://www.eetimes.eu/the-importance-of-sic-semiconductors-for-energy-efficiency/?_ga=2.143931573.1435390715.1675620467-1057662769.1675620467&_gl=1*1829dww*_ga*MTA1NzY2Mjc2OS4xNjc1NjIwNDY3*_ga_ZLV02RYCZ8*MTY3NTYyNDQ2OS4yLjEuMTY3NTYyNDQ3Ny4wLjAuMA.. (Accessed on 06 February 2023)

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.