Battery-powered devices are prevalent in society, which is only set to increase significantly as the electric vehicle market expands. This results in demand for higher-powered, longer-lasting, and better-performing batteries. With this comes the need for strengthened safety guidelines.

Image Credit: H.E.L Group

Manufacturers must consider the importance of temperature in achieving the best possible performance and properties for batteries. There are many factors to consider regarding temperature and batteries, and this is discussed below.

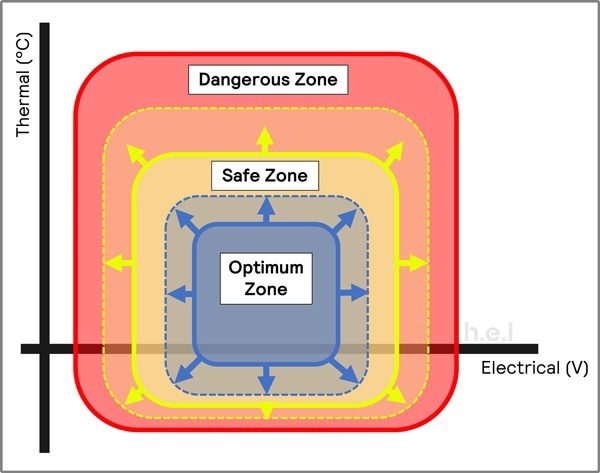

Battery temperature and electrical zone. Image Credit: H.E.L Group

Low Temperature

When exposed to prolonged periods of low temperature, the viscosity of battery electrolytes can increase, resulting in a continual decrease in performance. Eventually, the electrolyte will freeze solid, which has a severe and potentially irreversible impact on functionality and battery performance.

High Temperature

When exposed to relatively short periods of elevated temperature, potentially dangerous and catastrophic issues can occur with batteries. High-temperature exposure can reduce device lifespan and can lead to battery fires.

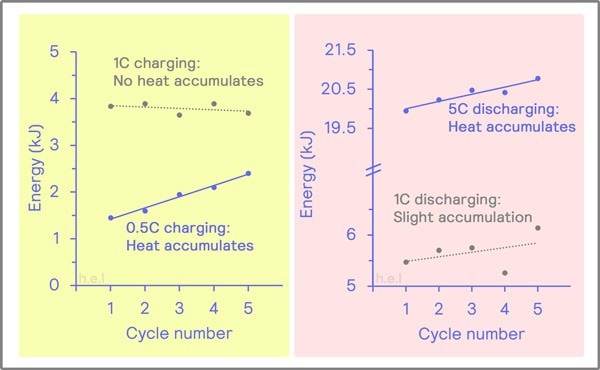

Batteries will naturally create and absorb heat throughout their everyday working life. This can change depending on environmental conditions, state of charge, charge/discharge rate, and device age. Therefore, when designing batteries, thermal management must be considered.

Cycle number/energy graph. Image Credit: H.E.L Group

Thermal Management

Failure to correctly manage thermal behavior can result in device damage, safety issues, and reputational damage for manufacturers and products. Many battery developers ensure that battery temperatures remain within tight set limits to ensure this does not happen.

Manufacturers often recommend a very narrow temperature range to ensure optimal conditions in battery-powered products. Battery performance can be restrained to limit heat generation. Some thermal management systems actively cool batteries while in use.

Understanding Thermal Behavior in Batteries

Knowing the battery’s thermal behavior and characterizing both the battery pack and individual battery cells is essential. This is because the heat generated by a single battery cell can rapidly dissipate into the environment. Therefore, there should not be any significant temperature increase in devices.

When a single cell is placed in a battery pack or module with other cells, less energy can escape the system due to the heat generated by multiple cells. This carries the danger of significant temperature rise and potentially catastrophic damage if thermal behavior is not understood correctly.

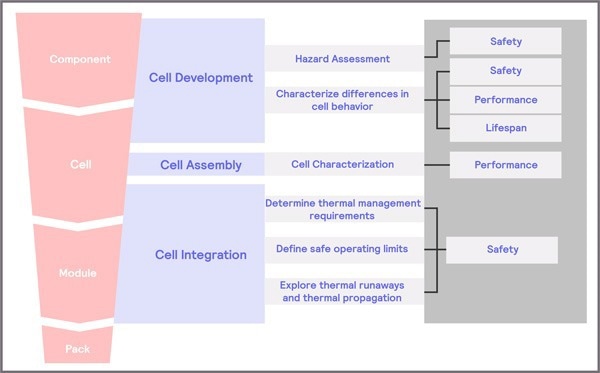

Image Credit: H.E.L Group

Understanding thermal behavior in batteries helps define and enhance safe boundaries and optimal operation. Reaction calorimeters can be used to simplify this process and enhance this understanding. Adiabatic, isoperibolic, and isothermal calorimeters can help determine safer operating limits.

Adiabatic calorimeters such as the BTC-500 and BTC-130 can be used for destructive testing of batteries in extreme temperature conditions, while isoperibolic and isothermal testing calorimeters, such as the iso-BTC and iso-BTC+, are non-destructive and can be used for the thermal characterization of batteries.

In Summary

The demand for more powerful, longer-lasting batteries is increasing. Stringent testing is needed to ensure that batteries function safely in extremes of temperature. Utilizing the proper equipment and testing determines the key zones (optimum, safe, and dangerous) of batteries.

It is crucial that manufacturers make informed decisions based on reliable and robust data. H.L.E Group provides the expertise and equipment to ensure that battery manufacturers have the tools needed to determine the thermal behavior and develop effective thermal management systems.

This information has been sourced, reviewed and adapted from materials provided by H.E.L Group.

For more information on this source, please visit H.E.L Group.