This article from H.E.L Group will discuss how to improve cell charging for testing on a Phi-factor cell. It will provide information that will help to enhance sample analysis and overcome common challenges.

Image Credit: H.E.L Group

Charging Liquid Samples in a Phi-factor Cell

A common approach is to charge the test cell outside the Phi-TEC-II and assemble the system. However, this is not always possible. For example, some reactions can start immediately when reactants are mixed.

While this is challenging, several methods can be used to add liquid to the test cell while the Phi-TEC-II is assembled and running. Some of these are listed below.

Using a Vacuum

A commonly used technique is to employ a vacuum on the test cell and connect the barrel of a syringe to the Phi-TEC-II using a bent Luer adapter. The syringe is charged with liquid, and upon opening the ball valve to the test cell on the feed line, this liquid is drawn into the system.

With careful coordination, the syringe can be topped up with more samples without breaking the liquid seal. Once the sample has been drawn into the test cell, the feed line is cleared by sucking air through the line.

One variation of this method can be utilized: filling the syringe using the barrel. Once the valve is opened, the liquid will be sucked in, pulling the syringe barrel down. An advantage of this method is that it allows additional manual pressure to be applied to the plunger if needed.

(Note: If a vacuum is pulled on the test cell, it is essential to create a vacuum in the main Phi-TEC II vessel – the test cells will take much more “positive” pressure than “negative” pressure. Pulling a vacuum on the test cell alone can crush it.)

Feed via Syringe

Similarly, the liquid can be injected via a syringe. While this means that the operator is injecting against pressure, if reaction and pressure build-up is unlikely to start when the liquid is charged immediately, a relatively large quantity of liquid can be added using this method.

This method has a few downfalls, however. The operator must close the valve before the syringe’s pressure is released. Some liquid can also remain in the feed line and not reach the test cell itself, leading to incomplete charging. Calculating feed amounts can take this into account.

In instances of low pressure, a syringe full of air can blow as much of the liquid as possible through the feed line. Narrow syringes allow more exertion of pressure. While this requires multiple injections, a smaller syringe allows easier and more comfortable injection at slightly elevated pressures.

High-pressure Injection

Using a syringe to charge a Phi-factor cell is not always possible. Some reactions can occur immediately on mixing, causing an immediate rise in pressure. Furthermore, the addition itself may need to be conducted under pressure.

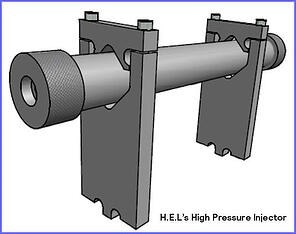

Custom high-pressure injectors, similar to syringes, are available from H.E.L. These systems consist of a barrel and a moving component analogous to a syringe’s plunger.

H.E.L’s High Pressure Injector. Image Credit: H.E.L Group

A manual syringe is used to charge the injector, which is then sealed and connected to the high-pressure gas feed line on the Phi-TEC-II. The injector’s open end is connected to a pressure source using nitrogen or another inert gas.

When the test cell needs to be charged, the injector’s valves and the feed line on the Phi-TEC-II are opened. Gas pressure forces the plunger to the end of the injector, which introduces the liquid into the test cell. The injector works even with relatively viscous liquids, though they may require higher gas pressure.

There is a downside to this method, however. Some liquid is still left in the feedline’s dead volume. This can be pre-quantified and taken into account. Extra liquid can be charged in the injector at the start of the process.

Feed Pumps

An HPLC pump can pump liquid into the test cell if a more controlled feed is desired. The possibility of pressure build-up requires the use of high-pressure pumps.

Pumps can be integrated into the controlling software to inject automatically at the desired point, or manually controlled. Dead volumes in the feed must be quantified and mitigated.

Charging Solid Samples on a Phi-factor Cell

To ensure optimal solid sample charging on a Phi-factor cell, first the solid must be melted and fed as a liquid. This works well with relatively low melting point solids. Heating these solids on a hot plate or similar equipment will produce a liquid that can be introduced into the test cell.

There are two considerations with this method. Firstly, the reagent must stay below the decomposition temperature. Secondly, the line must be clear to avoid residual solids forming and blocking the feed line. Careful pre-heating of the test cell and syringes/funnels will avoid initial cooling of samples.

Creating a Solution and Removing Solvent

Samples should be dissolved in a suitable volatile solvent and charged as a liquid, and the solvent evaporated. This can be achieved by applying heat and vacuum. Materials must be kept below their decomposition temperature, and complete solvent removal must be ensured.

Weighing the test cell at intervals until the mass stabilizes can be used to ensure complete solvent removal.

Use a Test Cell with a Larger Opening

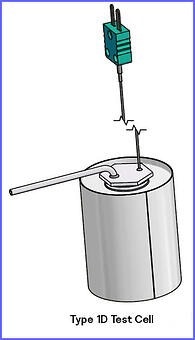

Type 1D test cells from H.L.E have a larger opening, making them suitable for solid samples.

Type 1D Test Cell. Image Credit: H.E.L Group

Final Thoughts

Sometimes, a bit of creativity is needed to adapt the methodology and fit the chemistry to the available equipment. Unfortunately, universal solutions are difficult to find. The methods presented in this article encourage an “out-of-the-box” approach to charging samples on a Phi-factor cell.

This information has been sourced, reviewed and adapted from materials provided by H.E.L Group.

For more information on this source, please visit H.E.L Group.