It is possible that users are not performing to the best of their ability when using an antique differential scanning calorimeter (DSC) or other outdated methods.

This can be the case when observing the thermal transitions and behaviors of plastic materials or lead-free solders against heat, researching nanomaterials in high-stress environments, conducting quality control tests such as measuring the melting fraction of milk chocolate, or determining the cracking point in caramel.

Seven key indicators should be considered to help determine if a lab requires an upgrade, and addressing these factors can significantly impact the job satisfaction and productivity of all lab members.

It is important to note that these tips are intended for everyone in the lab, regardless of their level of involvement with the DSC instrument. By implementing these suggestions, every member of the lab can contribute to the success of the applications for which a DSC is being utilized.

-

Your Calorimeter Loses Heat Signals

One common problem with calorimeters is that they can lose heat signals during operation, leading to uneven heating within the unit. This signal loss can result in inaccurate measurements and potentially an unreliable final result.

If an instrument's temperature during operation is hard to maintain, this is often the first sign that a lab requires an upgrade in differential scanning calorimetry equipment.

Selecting the appropriate DSC for a specific application requires careful consideration, as an excellent DSC can provide high precision and repeatability when measuring different samples. To get started, it is important to know the following:

- The kind of samples that need to be examined

- The kind of measurements that need to be taken of those samples

- What test conditions need to be created

It is also essential to determine whether the application requires real-time sample observation, analysis of photochemical reactions, or general DSC measurements.

A reliable differential scanning calorimeter can support the entire process, from research and development to quality control.

NEXTA DSC Series is an excellent option for such applications. It can perform various measurement processes for polymers, inorganic materials, pharmaceuticals, and food products, among others.

Moreover, it allows for the physical observation of crystallization and glass transition of samples at low temperatures of up to -50 °C, providing unique insights into material behavior.

-

Your Calorimeter Does Not Support Temperature-Modulated DSC Techniques

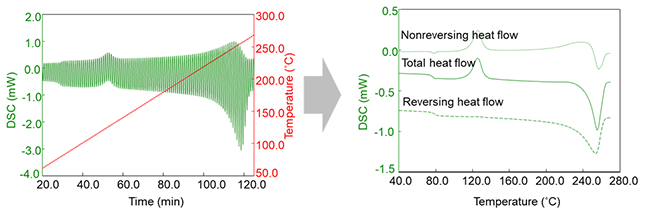

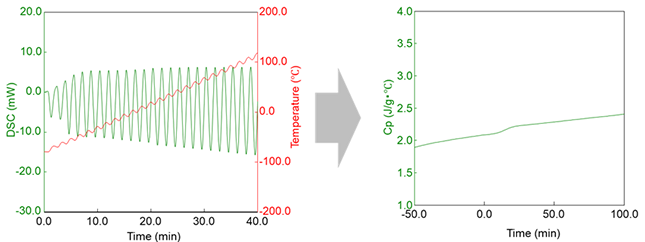

Temperature-modulated DSC (TM-DSC) is a technique that modulates the temperature change sinusoidally to yield an average rate of three signals simultaneously.

This technique provides the total heat flow, which is similar to the traditional DSC curve, while the reversing heat flow and non-reversing heat flow enable independent observation of the reversing and kinetic components, respectively.

TM-DSC can separate the reversing and non-reversing changes that overlap in conventional DSC measurements.

TM-DSC is particularly useful in cases where the glass transition cannot be identified clearly from DSC data due to overlapping non-reversible phenomena. Figure 1 illustrates the effectiveness of TM-DSC in isolating the glass transition from the standard DSC curve to identify it distinctly.

Figure 1: Modulated Temperature DSC example for separation of reversing and non-reversing heat flow. Image Credit: Hitachi High-Tech Analytical Science

TM-DSC allows for direct measurement of heat capacity, as demonstrated in Figure 2, which shows the heat capacity results of polyurethane obtained using MT-DSC.

Figure 2: Modulated Temperature DSC example for direct Cp measurement of polyurethane. Image Credit: Hitachi High-Tech Analytical Science

-

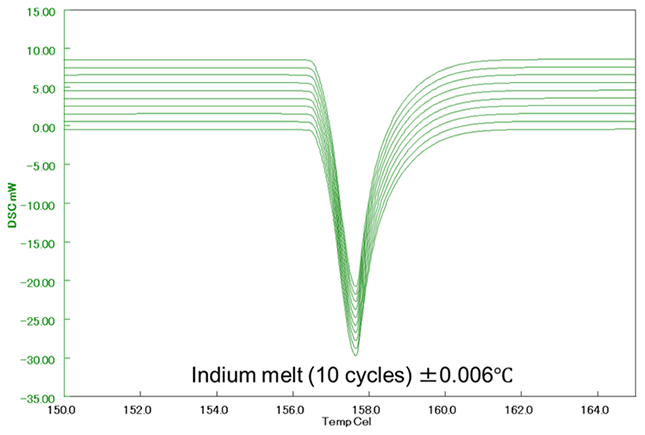

Your Measurements Are Not Consistently Repeatable

Temperature and calorimetric repeatability are essential aspects of differential scanning calorimetry. Simply sticking a sample in an oven with a thermometer proved inefficient in obtaining the necessary consistency for reliable data.

Regardless of the size of the sample pool, achieving consistency in successive calorimetry measurements is crucial to ensure reliable data. The reputation, capabilities, and daily work of testing labs depend on this consistency.

Figure 3: Example of good repeatability. Image Credit: Hitachi High-Tech Analytical Science

If measurements are not consistently repeatable, this may be a sign that a lab would benefit from a new DSC. When selecting a new DSC, it is important to consider how tight the repeat values need to be for your particular industry.

While some labs may be content with slight temperature variations, for others, even the slightest variance can compromise the entire product. Therefore, it is always advisable to choose a differential scanning calorimeter that provides tighter repeat values than what may be needed, erring on the side of caution.

-

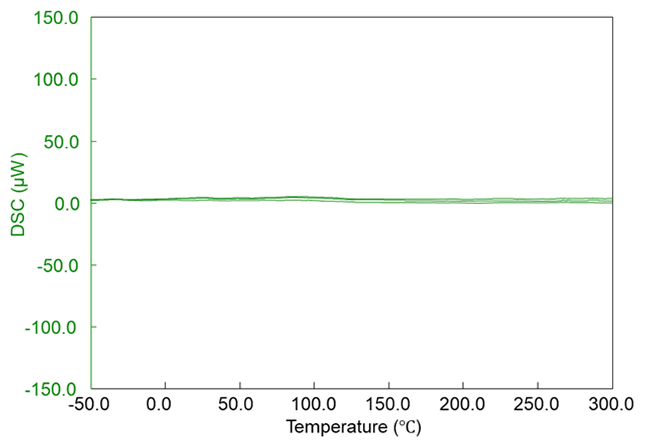

Your Baselines Fluctuate

Achieving accurate and consistent baselines is crucial for the repeatability of calorimetry measurements. It ensures that observed thermal transitions are attributable to the sample and facilitates confident measurement of even the smallest thermal transitions. Inaccurate baselines can result in incorrect measurements across the board.

It is essential to have a stable baseline temperature to avoid fluctuations during measurement.

The NEXTA DSC instruments are designed to provide the most stable baseline temperatures currently available. With these instruments, the chances of incorrect measurements caused by heat fluctuations during measurement are eliminated.

These DSC instruments achieve a highly stable baseline of +/-5 µW within -150 - 725 °C, which is crucial for many quality control processes.

Figure 4: Example on how baseline repeatability should be. Image Credit: Hitachi High-Tech Analytical Science

-

Your Calorimeter Misses Small Changes Between Transitions

Differential scanning calorimetry (DSC) is commonly used by industries that require high sensitivity and a low tolerance for error or variation.

Pharmaceutical and biochemical testing companies often use DSC equipment to measure:

- Binding interaction

- Material stability

- Product purity

Inaccurate measurements due to inadequate sensitivities in DSC testing can reduce the number of samples that can be accurately measured.

In ultra-sensitive applications, such as testing for purity in pharmaceuticals, unreliable baselines and missed transitions or behavior changes can compromise the entire testing cycle and the product being tested.

To address this issue, the NEXTA DSC Series offers superior temperature stability, better-following capabilities, and reduced baseline fluctuation, thanks to a furnace equipped with single or multiple thermocouples and a three-layered insulation furnace design.

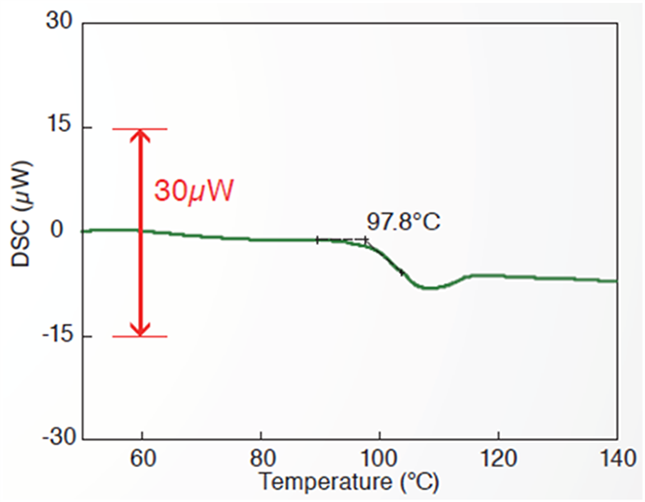

The NEXTA DSC600 utilizes a proprietary thermopile-type DSC sensor that offers a high sensitivity of 0.1 µW or lower, making it an ideal solution for many labs and enabling users to capture the entire depth of transitions.

As a result, the overall repeatability and sensitivity of DSC analysis performed in the lab are significantly improved.

Figure 5: Example of a detection of small thermal transition obtained with our NEXTA DSC600. Image Credit: Hitachi High-Tech Analytical Science

-

Your Calorimeter Does Not Know How to Be Cool

Cooling units are an essential component of DSC testing equipment as they reduce or eliminate troublesome exchanges and enable the performance of various types of testing.

The cooling process that takes place after a material is heated provides valuable insight into the sample's behavior.

Therefore, DSC testing equipment that can integrate with cooling units is ideal for most operators. Without this feature, the range of sample types and phases that can be measured is limited.

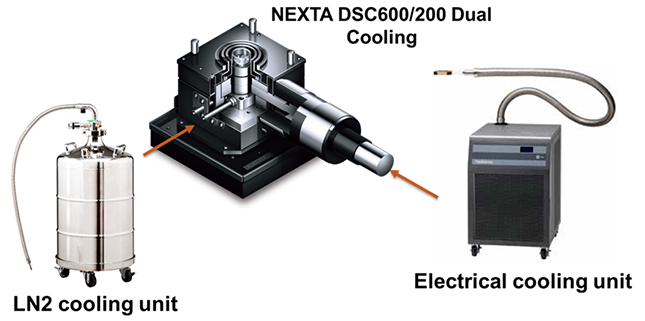

There are three types of cooling options available for DSC testing: air cooling, electrical cooling systems, and LN2 cooling systems.

Electrical cooling is suitable for industries that require precise control over cooling temperatures, and the cooling rate can be accurately controlled with just electricity.

The controlled cooling rate and lowest temperature are limited by the type of electrical cooling used. For DSC operators measuring crystallization or recrystallization, electrical cooling is the best option to effectively analyze material behavior.

LN2 cooling allows better cooling rate control and gives the option to reach lower temperatures than electrical cooling. The only drawback is that the Dewar needs to be regularly refilled.

The NEXTA DSC series offers a dual cooling feature on a single system, providing the necessary flexibility for sporadic liquid nitrogen cooling needs.

Figure 6: Dual cooling with NEXTA DSC600/200. Image Credit: Hitachi High-Tech Analytical Science

-

Your Differential Scanning Calorimeter Does Not Support DSC System Expanding and Upgrading Functions

A high-quality calorimeter can take precise and consistent measurements, but an exceptional DSC calorimeter can simplify work and broaden testing options by supporting expansions that enhance testing processes.

By utilizing a calorimeter that can pair with additional measuring accessories, users can:

- Diversify the kinds of testing that can be carried out

- Simplify routine testing procedures

- Maximize testing volumes

This information has been sourced, reviewed and adapted from materials provided by Hitachi High-Tech Analytical Science.

For more information on this source, please visit Hitachi High-Tech Analytical Science.