Dynamic mechanical analysis (DMA) is a technique utilized to determine the viscoelastic characteristics of materials, particularly polymers, by subjecting them to a continuous, oscillating load (strain or stress) that remains consistent over time.

The primary purpose of DMA is to detect glass transitions, but it is also applicable in measuring secondary transitions, stiffness of materials, curing level, and crystallinity.

How Does DMA Work?

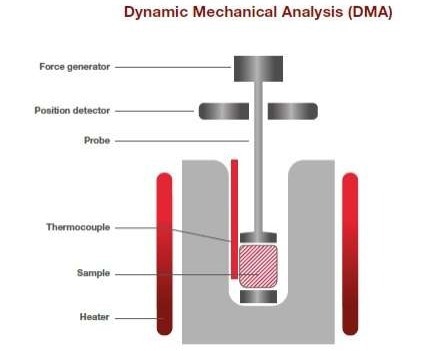

In the DMA instrument, a sample is securely clamped in the measurement head and subjected to a sinusoidal force while the temperature is adjusted in a controlled manner. The relationship between the applied force and the resulting deformation is then measured.

Image Credit: Hitachi High-Tech Analytical Science

The properties of the sample, including elasticity and viscosity, can be computed from the stress and strain applied, which are plotted as a function of temperature or time.

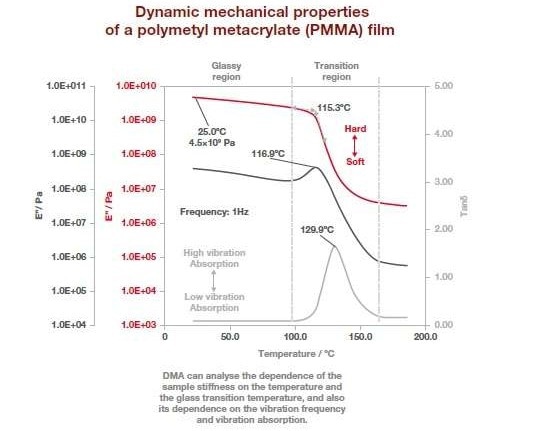

Image Credit: Hitachi High-Tech Analytical Science

The DMA measurement generates three parameters that are usually plotted in the output trace.

The first is E’, which is the storage or elastic modulus and indicates the elastic properties of the sample, as well as the extent of energy that is stored and recovered against the applied force.

The second parameter is E”, which is the loss or inelastic modulus and reflects the viscous properties of the sample, as well as the degree of energy that is transformed into heat against the applied force.

Finally, Tanδ, also known as the vibration absorption coefficient or damping, is the loss tangent that illustrates the ratio of E’ to E” and demonstrates the vibration absorbability of the sample.

These parameters provide valuable information about the changes in stiffness and damping of the polymer across a temperature range.

DMA Provides Insight into Different Thermal Properties

Dynamic mechanical analysis is a valuable technique for measuring changes in stiffness and damping in response to temperature variations, providing insights into the impact of temperature on the physical properties of materials.

The high sensitivity of DMA enables the detection of relaxation phenomena, including glass transition, side-chain relaxation, and local mode relaxation, offering a means to investigate the molecular structure and motion of polymers

By conducting simultaneous measurements of temperature dispersion and frequency dispersion, it is possible to assess the effect of frequency on material properties and its influence on relaxation transitions. This allows for a better understanding of the behavior of materials under actual use conditions.

DMA can be utilized to determine either shear modulus (G) or Young’s modulus (E).

Interpreting Results for a DMA Analysis to a Specific ASTM Method

The selected standard for analysis is ASTM D4065-20, which is widely regarded as the best practice for determining and reporting procedures for plastics.

The purpose of this practice is to provide a method for determining the transition temperatures and elastic and loss moduli of plastics over a range of temperatures, frequencies, or time using free vibration and resonant or non-resonant forced vibration techniques.

Elastic and loss moduli plots are typically indicative of the viscoelastic characteristics of a plastic. These moduli are dependent on temperature or frequency in plastics and exhibit rapid changes at particular temperatures or frequencies. These regions of rapid moduli change are commonly referred to as transition regions.

The referenced test methods list various modes of deformation, such as tensile, bending, and shear.

The DMA thermograms displayed in the analysis show the outcomes for a polymethyl methacrylate (PMMA) film tested under tension. The three curves represent different information related to the material’s viscoelastic behavior.

The storage modulus, denoted by E’, provides information about the material’s elastic component, which corresponds to its stiffness.

The modulus value at 25 °C can be utilized to measure the stiffness of the material. For amorphous or partially amorphous materials like PMMA, DMA is the ideal technique for detecting the glass transition (Tg) due to its high sensitivity.

In the case of PMMA, the glass transition temperature from the storage modulus is detected at 115.3 °C.

Additionally, the glass transition can also be detected using E”, which is the loss modulus. The peak detected in this manner is 116.9 °C. Tanδ can also be utilized to detect the glass transition at 129.9 °C as well as to evaluate the material’s vibration absorption ability or damping.

It is typical for E’, E”, and Tanδ to yield different values as they measure different properties of the polymer. However, it is important to compare results obtained with the same type of measurements (E’, E”, or Tanδ) for consistency.

The Advantages of Using DMA

DMA is commonly utilized for detecting weak transitions, such as glass transition, as well as for determining the viscoelastic properties and relaxation of polymers and how they are influenced by frequency.

It can examine larger samples that are similar to those utilized in actual parts. The various measuring heads also enable measurement in a manner that closely resembles the way materials are intended to be used, such as tension or shear mode.

Hitachi’s DMA Analyzer for Visibly Better Thermal Analysis

The DMA instruments offered by the company provide a range of benefits to users. These include the ability to detect changes in modulus, gain insights into unexpected sample behaviors, and ensure the reliability of data points.

One of the key products, the DMA7100, can accommodate a wide range of samples, including those that are very soft or stiff. It also allows users to select from various deformation modes.

In addition to these features, the DMA7100 Series is equipped with advanced capabilities such as TTS and activation energy calculations. These tools are especially useful in the characterization of thermoplastics, thermosets, and polymer blends. The system is also well-suited for conducting curing studies on composites.

The Real View® camera system is an innovative feature that is integrated seamlessly with the DMA7100 Series. This tool enables users to observe changes in the sample’s shape, size, color, and other properties in real time during analysis.

Images can be recorded and linked to thermal data by timestamp, providing a comprehensive record of the testing process.

This information has been sourced, reviewed and adapted from materials provided by Hitachi High-Tech Analytical Science.

For more information on this source, please visit Hitachi High-Tech Analytical Science.