Implementing sustainability improvements in commercial construction is poised to be the way forward. As the global population continues to grow and environmental alterations become more pronounced, there is an increasing demand for heating, ventilation, and air conditioning (HVAC) systems in construction.

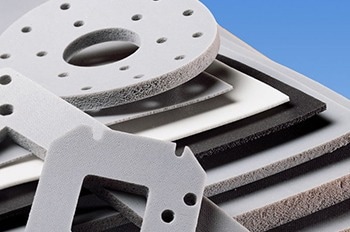

Image Credit: Saint-Gobain Tape Solutions

As the "respiratory system" of buildings, it is imperative to explore avenues for enhancing or revolutionizing HVAC systems as part of the effort to achieve carbon neutrality.

HVAC systems account for 40-60% of the energy consumption in buildings, which equates to roughly 15% of the global energy consumption. Enhancing the efficiency of HVAC systems is critical for achieving significant energy savings.

Enterprises are increasingly investing in sustainable technologies and equipment that consume less energy to heat, cool, and operate appliances. Such efforts are aimed at collaborating to achieve net-zero carbon emissions.

The design phase presents a substantial opportunity for improving the efficiency of HVAC systems. A well-planned design can effectively reduce energy consumption while ensuring a safe and comfortable indoor environment. Design engineers consider all HVAC system components to achieve optimal performance and energy savings.

In particular, the use of high-quality gasketing and sealing materials in HVAC applications can lead to reduced energy bills and a healthier indoor environment with fewer pollutants and less dust, providing significant health benefits.

Gasketing and Tape Solutions for Modern-Day HVAC Needs

The following are some of the most common gasketing requirements in HVAC applications:

- Sealing: To effectively address the dimensional variations and uneven edges commonly encountered in HVAC ductwork, a soft material with suitable thickness and good compressibility is recommended. Since metal ductwork is prone to dimensional changes and shifts as a result of warm and cool air circulation, gaskets that ensure leak-tight sealing and possess excellent compression recovery are ideal for responding to these frequent changes.

- Reducing vibration transmission: The cellular structure of a gasket can help absorb vibrations generated by HVAC fans and motors, reducing the low humming sounds that may otherwise cause noise complaints from building occupants. Using gasketing materials for this purpose can be beneficial in HVAC applications.

- Environmental resistance: HVAC systems, particularly those in commercial settings, are often installed outdoors, such as on rooftops. Therefore, gasketing solutions for outdoor HVAC applications need to be resilient to environmental factors such as water seepage, dust, and sunlight. Suitable solutions may include PVC, EPDM, neoprene rubber, or premium silicones. The most effective solutions can withstand the challenges of UV lighting, extreme temperatures, moisture penetration, and ozone resistance.

Saint-Gobain® offers a diverse range of products, including thermally conductive materials, polyurethane, and PVC foam materials, which are suitable for various HVAC requirements.

Its sealing and gasketing materials are designed to prevent leakage both in and out of the system boundaries, enabling consistent air quality and thermal comfort in indoor environments.

Modern Day Commercial HVAC

Many commercial buildings, including offices, hospitals, laboratories, and factories, use centralized HVAC systems. These systems heat or cool the air in a central location and then distribute it to various rooms through fans and ductwork.

The Air Handling Unit (AHU) is a critical component of centralized HVAC systems and is often regarded as the heart of central air conditioning.

Modern building design. Image Credit: Shutterstock/hallojulie

AHUs are responsible for creating comfortable, high-quality indoor air by collecting air from the outside, filtering it, and then heating, cooling, humidifying, or dehumidifying it as it passes through the unit.

This process ensures that the air circulating throughout the building meets the optimal conditions for each room.

AHUs consist of a large metal enclosure that houses several components, including a blower (fan), a heat exchanger, filter chambers, a humidifier, dampers, and sound attenuators.

The distribution of conditioned air to different zones in a commercial building depends on whether the AHUs use Constant Air Volume (CAV) or Variable Air Volume (VAV) control.

While CAVs maintain a constant airflow while varying temperatures, VAVs maintain constant temperatures while supplying variable airflow. The VAV system is more modern and efficient, with the ability to adjust to changing demand within a building and reduce the supply of treated air in areas where it is not required.

A VAV-based air distribution system includes AHU and VAV boxes, with one VAV box assigned per building zone and linked to a dedicated thermostat.

Air Handling Unit in metal box enclosure on rooftop of commercial building. Image Credit: Shutterstock/Dmitriy Kuznietsov

The HVAC system comprises dampers that regulate airflow based on zone temperature sensors. These dampers function by preventing air from circulating into areas that do not require heating or cooling, conserving energy and also protecting against smoke or fire.

VAV systems also include Smart Air Valves, which use intelligent air control to manage airflow and maintain optimal air change rates, reducing energy consumption and improving comfort.

Although the initial cost of demand control ventilation systems, such as VAVs, may be higher, they are the preferred choice for modern, energy-efficient buildings.

HVAC damper with gasketing. Image Credit: Shutterstock/Nikita Rublev

Enhancing HVAC Energy, Safety, and Performance

For HVAC systems to perform efficiently and with high performance, the use of sealing and gasketing materials is essential. These materials serve to seal access panels, louvers, and doors, and also reduce any undesired noise caused by vibrations from the system's motor or fan.

It is crucial to use sealing and gasketing materials that prevent unwanted air leaks and energy waste. In addition, these materials should allow for thermal expansion and contraction.

The Saint-Gobain product portfolio offers a range of high-performance silicone, polyurethane, and PVC foams that are specifically designed to meet the demanding needs of HVAC applications.

Silicone Foam Rubber

Despite being more expensive, premium silicone materials exhibit exceptional performance in applications that demand excellent flame retardancy, low toxicity, and minimal smoke generation.

Norseal® Silicone Foams are well-suited for a range of applications, including fireblocks, thermal barriers, noise and vibration dampeners, and insulation. Their exceptional resistance to weather, moisture, ozone, UV, and fungus makes them an excellent choice for gasketing materials, especially in outdoor applications.

Norseal F-12 possesses a distinctive cellular structure, excellent high-temperature stability, inertness, and minimal compression set. It is a top-quality, pliant, and readily compressible silicone foam that is highly suitable for use in applications that demand superior resistance to elevated temperatures and fire retardancy.

Potential applications for Norseal F-12 include controlling ventilation dampers and sealing enclosures located near the heating section of an air handling unit (AHU). With its UL94 V-0 rating, this product is particularly effective in upholding the safety and performance standards of a commercial HVAC system.

Die-cut Norseal Silicone Foam Rubber. Image Credit: Saint-Gobain.

In addition, Norseal F-12 is highly suitable for use in smart valves owing to its ease of compression, minimal compression set at elevated temperatures, capacity to be die-cut for precise fitting within the valve, resistance to microbial growth, and ability to function as a gasket for both the inner and outer damper.

Norseal F-20 is a medium-density silicone foam that offers increased durability in sealing applications. It exhibits exceptional resistance to compression set, along with excellent flame resistance (UL94 V-0), low toxicity, and minimal smoke generation.

This product is frequently utilized in outdoor sealing applications, as it provides exceptional resistance to environmental conditions and exceptional water sealing capabilities.

SNS Silicone Tapes

Norseal Silicone can be obtained with the choice of Silicone or Acrylic pressure sensitive adhesive. SNS Tapes are highly compressible, flexible, and capable of conforming to irregular surfaces and shapes for sealing and gasketing purposes. These tapes are also ideal for vibration-dampening and thermal insulation applications.

Norseal SNS100S and 200A are specifically engineered to produce gaskets that can endure high temperatures without requiring the use of complicated tools. These products are ideal for use on access panels or inspection doors situated near burners or other heating elements.

Polyurethane Gasketing Foams

Norseal Polyurethane Gasketing Foams (PUR) are easy to apply and possess excellent gap-filling, cushioning, and environmental resistance properties, making them a reliable option for gasketing or sealing needs in HVAC applications that involve moderate temperature ranges (up to 212 °F/100 °C).

These foams are ideal for safeguarding against mechanical or environmental stressors, as they function to dissipate stress and motion while dampening shock and vibration. By doing so, they aid in protecting the longevity and overall performance of the system.

The micro-cellular structure of PUR gaskets facilitates exceptional resiliency, enabling frequent opening and re-closing of service doors within HVAC systems. This characteristic ensures pain-free maintenance and consistent sealing of the foam gasket in panel applications.

PVC Gasketing Foams

Norseal Foam Gaskets are a cost-effective option for applications that require less severe temperature requirements (160 °F). Although they exhibit good compression properties and are highly conformable, they are best suited for fixed joint applications where they can readily adapt to irregular surfaces.

Norbond® Bonding Tapes to Enhance HVAC Aesthetics

Saint-Gobain Tape Solutions also provides other material options for HVAC applications, such as the Norbond Bonding Tapes, which are utilized for emblem and frame bonding in HVAC systems.

These tapes can be die-cut into various shapes and sizes and possess excellent resistance to external environmental stressors, such as harsh weather, fungi, or oxidation. Bonding tapes offer an ideal solution for creating more lightweight HVAC systems by eliminating the requirement for mechanical fasteners, rivets, and screws.

Making the Right HVAC Material Choice

The installation of HVAC systems and the associated air handling units (AHUs) can be a challenging and expensive process. Therefore, it is crucial to include appropriate gasketing solutions to ensure optimal performance of the AHU.

Choosing the appropriate gasketing materials can safeguard the AHU against environmental stressors and ensure the efficient operation of all internal components. Common causes of HVAC unit breakdown include overheating, vibration damage, or seal and gasket failure.

By utilizing premium silicone foam and sponges, HVAC design engineers can increase the efficiency and longevity of the HVAC process, reduce the need for repairs, and enhance the safety and security of building occupants.

It is important to note that there is no one-size-fits-all gasket solution for every HVAC application. Selecting the appropriate gasket can help address common HVAC issues. The ideal solution will depend on various factors such as temperature resistance, compression requirements, environmental factors, and cost.

To meet specific functional or aesthetic requirements, Saint Gobain offers customized gasketing solutions that take into account the anticipated environmental conditions and expected wear over the lifespan of the HVAC system.

This information has been sourced, reviewed and adapted from materials provided by Saint-Gobain Tape Solutions.

For more information on this source, please visit Saint-Gobain Tape Solutions.