Ahead of their exciting presence at ChemUK this May, AZoM spoke with BASF's Senior Sustainability Manager, Tony Heslop, about 'the Impossible Bottle' and the work they are doing to achieve Net Zero by 2050.

Please can you introduce yourself and your professional background?

I am currently Senior Sustainability Manager for BASF in the UK and Ireland. I studied chemistry at university before working in the coatings industry, where I worked in the lab, went through technical services, and then into sales in raw materials. I spent a few years in sales at BASF, then went into market development, and five years ago transitioned into sustainability for the UK.

Who is BASF, and what products and services does the company offer?

We are the world's largest chemical company, and our portfolio is broad. Key markets for us in the UK include the automotive industry. We provide a lot of automotive coatings as well as plastics and fluids that go into cars, trucks, or buses. We are also heavily involved with construction in terms of things like insulation. Beyond that, there are the healthcare, pharmaceutical, human nutrition, and animal nutrition markets. We make everything from basic chemicals right through to formulated products and everything in between.

BASF SE, with its main site in Ludwigshafen, is the heart of the BASF Group. With around 250 production facilities, hundreds of laboratories, technical centers, factories, and offices in an area of approximately ten square kilometers, the site is the largest integrated chemical complex in the world. Image Credit: BASF SE

BASF wants to achieve net-zero emissions by 2050. What are some of the ways that the company is approaching this challenge?

On our journey toward climate neutrality, we have set ourselves ambitious goals and are striving worldwide to achieve net zero CO2 emissions by 2050. In addition, we want to reduce our greenhouse gas emissions worldwide by 25 percent by 2030 compared with 2018. Excluding the effects of planned growth, this means cutting CO2 emissions in half in the current business by the end of this decade.

At the heart of the long-term transition toward net zero CO2 emissions by 2050 is the use of new technologies, which will replace fossil fuels such as natural gas with electricity from renewable sources. Most of these technologies are being pioneered by BASF in collaboration with partners and are currently in a pilot stage. Broad scale-up of these technologies will only be fully realizable after 2030. These activities have been bundled into our carbon management approach.

Our carbon management plan has five levers:

- Grey-to-green lever - We are increasingly meeting our energy needs from renewable sources

- Power-to-steam lever - We are increasingly relying on energy recovery to produce steam

- Continuous OpEx lever - We are working to further improve the energy and process efficiency of our plants

- Bio-based feedstocks lever - We are increasingly replacing fossil resources with renewable raw materials

- New Technologies lever - Together with partners, we are pioneering nearly carbon-free production processes, especially for emission-intensive basic chemicals.

If you’re interested in finding out more about our carbon management, you find more information here.

Why is sustainability in the chemical industry particularly hard to achieve?

The chemical industry is complex, and its products underpin many different value chains. Innovation in the chemical industry will help meet global societal needs and will provide future solutions that help to reduce emissions. However, we recognize that the chemical industry is also part of the problem. Chemical production processes are still too intensive in terms of fossil energy and CO2 emissions. At BASF, we are already fundamentally reinventing the way chemicals are produced and the role chemistry can play in creating a truly sustainable world.

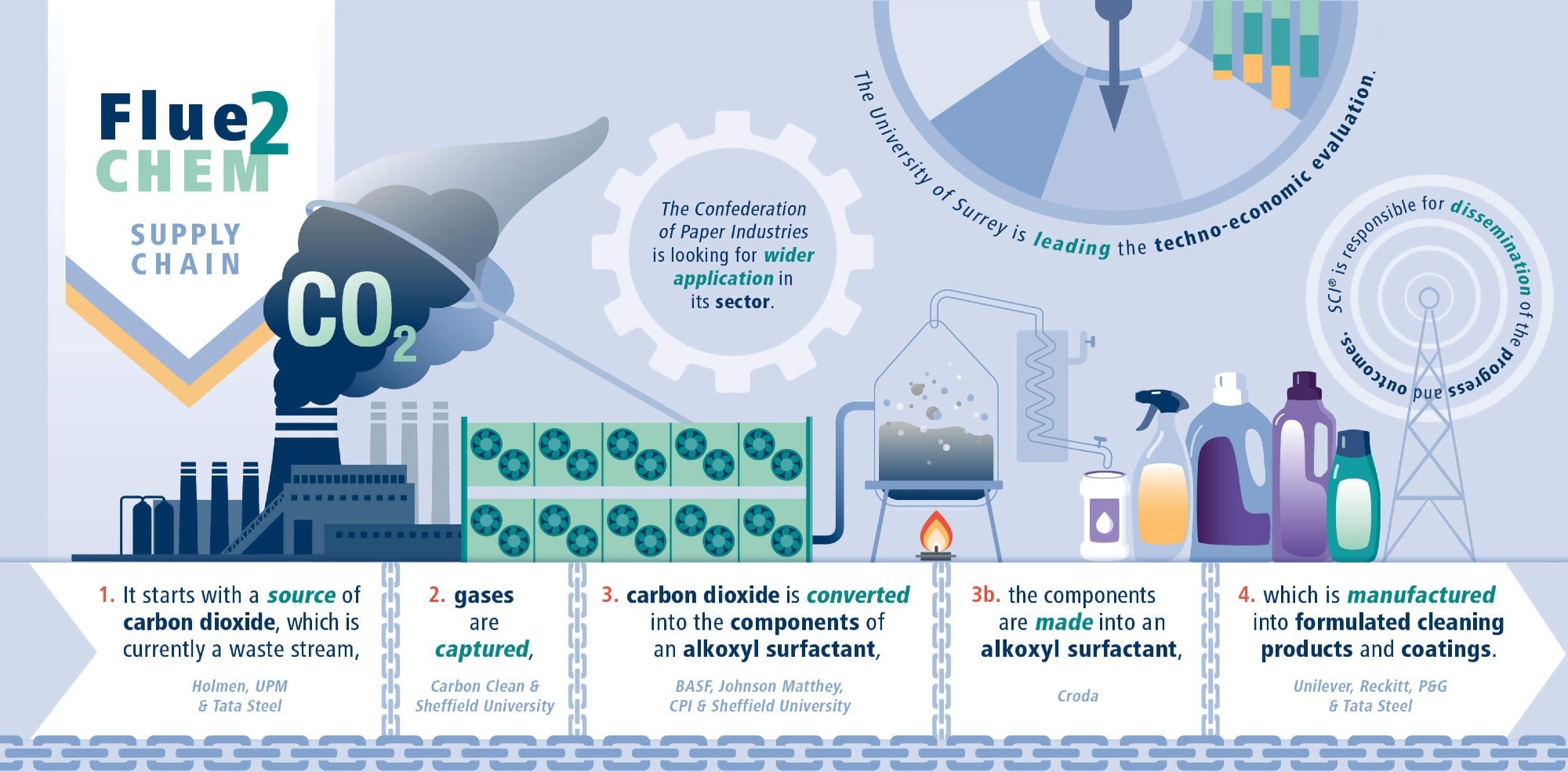

Image Credit: SCI®

A recent example I can share is that BASF and 14 other organizations have signed a collaboration agreement to launch a two-year project ‘Flue2Chem’ - a collaborative program to transform the sustainability of the UK’s consumer products industry and reduce greenhouse gas emissions on a demonstration scale. This is an exciting innovative step to help the UK reach its net zero targets, I urge you to read more here.

BASF will be attending ChemUK in Birmingham this May and will be bringing an exciting program. Could you tell us about the ‘Impossible Bottle’ talk you will be conducting there?

Over the past three years we’ve been working with Pulpex (a spin-off from the drinks brand owner Diageo) on the development of a paper bottle. This talk, ‘The Impossible Bottle’ details the innovation process that took place to develop this new packaging format.

Pulpex came to us when they had developed a process to produce bottles from paper pulp. They needed a technology partner to help make their bottles hold a variety of different liquids. BASF was able to provide solutions that balanced the need to hold liquid in the bottle, but also for the paper to remain repulpable so that it could be recycled through existing paper collection schemes.

There have been many challenges along the way. As interest grew, other FMCG brand owners joined the consortium and BASF was tasked with finding a solution to hold a wide variety of liquids, such as detergent and engine oil, each having their own distinct characteristics. In the end, there is no ‘one size fits all’ and custom solutions have been developed for each liquid, depending upon the performance required.

The finished product is a bottle that meets performance needs as a packaging solution but is fully recyclable through existing paper collection schemes. We look forward to seeing Pulpex bottles on retail shelves very soon.

How quickly do you believe your paper composite for food and beverages can be scaled and widely adopted?

The technology's there, and it's been a journey. I would say we're about 99% complete. It's not intended to be a plastic replacement or a glass replacement, or a tin replacement, just another solution for certain particular niche applications.

At the minute, Pulpex has a pilot facility just outside of Cambridge, which has the capability to make thousands of bottles. A new factory is currently in construction near Derby that can produce bottles at scale.

What more can visitors expect from BASF’s presence at the show?

BASF is represented at ChemUK through our distribution partner BTC, who have a stand at the exhibition – so feel free to call in for a chat. We have several speakers participating in the speaker program. On day one, our Managing Director, Thomas Birk, will give a keynote speech. Later that afternoon, Neil Hollis, Regulatory Affairs Manager, will host a panel session on the topic of UK REACH.

On day two, I am hosting a panel session called ‘Navigating Net Zero’. This session builds upon an event recently held at our UK Headquarters in Stockport which aimed to help customers take their first steps on their Net Zero journey. For the panel discussion, I will be joined by representatives from three chemical companies who will share their own progress to date, some of the challenges they have encountered, and how they’ve overcome them. I’m looking forward to a lively and interactive discussion.

Why is it important for BASF to engage with in-person conferences like ChemUK?

On the one hand, there is the human interaction. When you want to have discussions with people often on quite complex topics, and you want to build networks and relationships, it has to be face-to-face.

I think the second reason is actually the importance of having somewhere for our industry to go because we haven't had that in the past. And it's one of the reasons why I think we sat up and took an interest in CHEMUK right from the very start.

The chemical industry in the UK has largely, for many years, been anonymous. And it’s important to say, "Look at us, we're here, we're visible and are a considerable contributor to the UK economy."

About Tony Heslop

Tony Heslop is Senior Sustainability Manager for BASF in the UK and Ireland. He is a chemist by training and has taken on many professional roles within the chemical industry over the course of his career.

Tony Heslop is Senior Sustainability Manager for BASF in the UK and Ireland. He is a chemist by training and has taken on many professional roles within the chemical industry over the course of his career.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.