Could you please explain what a CRL transfer system is and how it is used?

Jeet Patil:

CRL leverages almost 80 years of proven innovative industry experience in designing and manufacturing bespoke, high-quality transfer solutions for use in hazardous and sterile material-handling applications, such as Rapid Transfer Ports (RTPs). CRL offers a wide range of Alpha and Beta solutions that can be implemented in many end-user product-transfer systems.

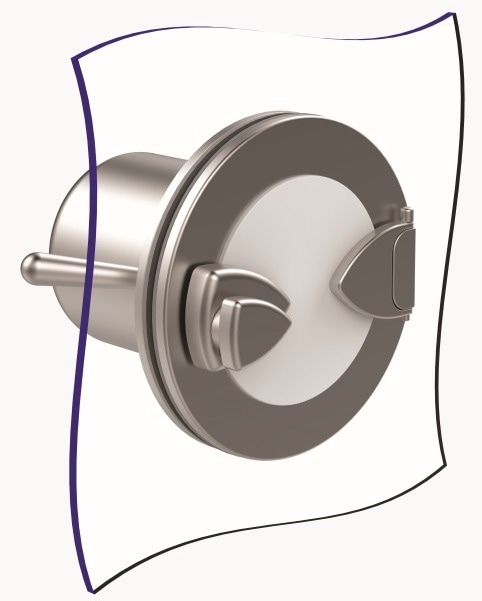

An RTP consists of an Alpha flange or female port, permanently mounted on an isolation chamber or cleanroom wall, and a Beta flange or male port, which is docked onto the Alpha flange via a bayonet (connection) action.

The door can be opened when the Beta flange is docked correctly to the Alpha flange. To prevent contamination, the RTP in this application uses a double-door design principle, i.e., the port into the container may not be opened until the Alpha and Beta ports are appropriately connected. The port to the container cannot be opened until the Alpha and Beta ports are docked together (hence the ‘double-door’ principle).

CRL Rapid Transfer Ports (RTPs) are used to safely transfer potent or hazardous materials. Image Credit: Central Research Laboratories

There are two different types of connection between the Alpha and Beta flanges: the first is where a non-rotating Alpha is firmly fixed to the wall of the isolator, and the Beta flange is rotated onto the Alpha flange to create the connection. This is the typical style used in 99% of cases.

Alternatively, a rotating Alpha is connected to a fixed Beta flange; this type of setup is typically used when the Beta is filled with fluids, cannot rotate, or is very heavy. However, this style is scarce mainly due to system cost and the technical complexity needed to help ensure a contamination-free connection.

There are two types of door openings for use in these systems. In the most common internal door-opening system, the door is manually opened by a technician physically located inside the isolator.

However, there has been a shift toward the creation and use of external door openings, as Good Manufacturing Practices (GMP) in handling sterile or aseptic products or components are beginning to dictate how a person’s hands play a role in the transfer process.

The door in this design is opened from outside the isolator so that there is no human interaction with the sterile/aseptic component or product being handled.

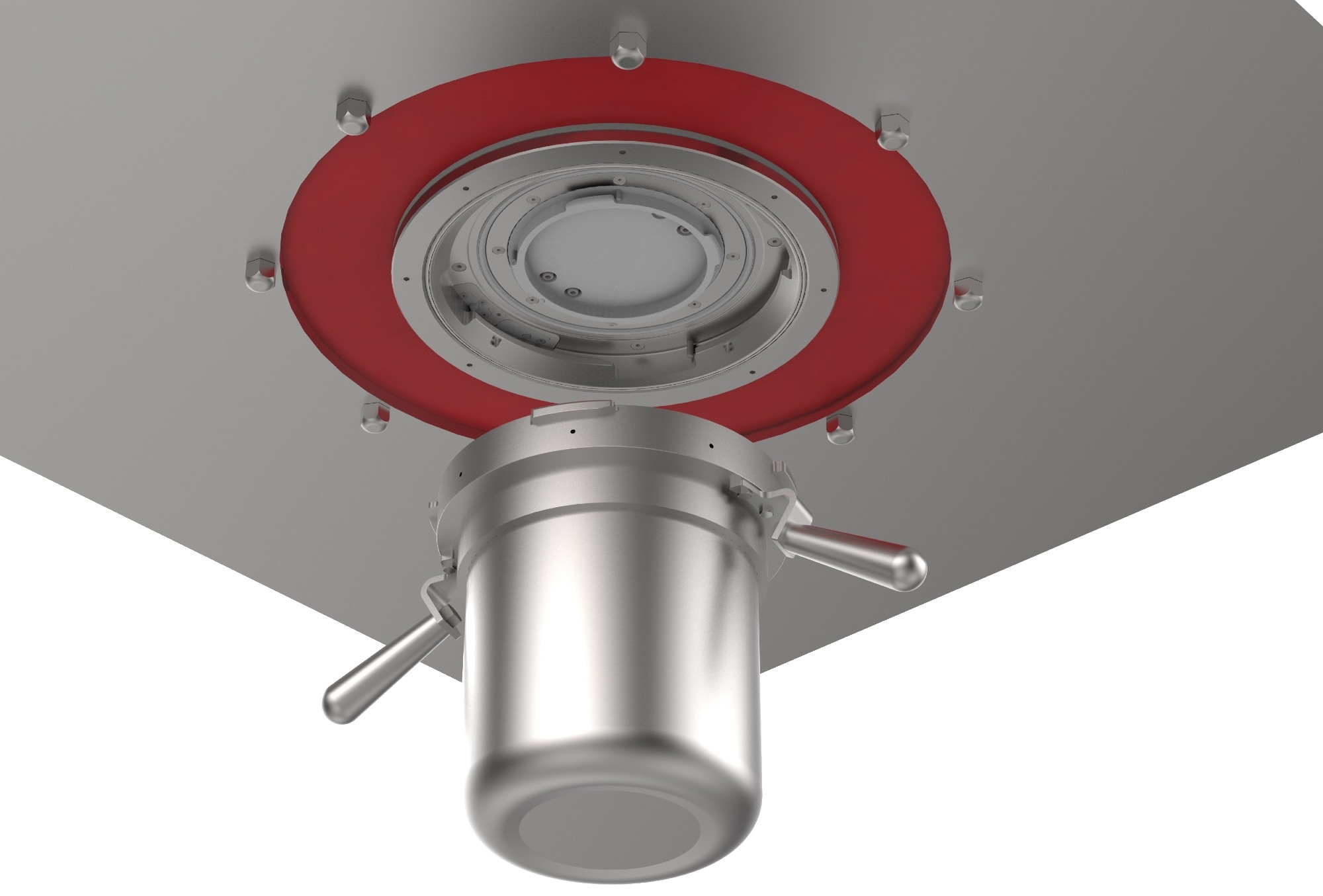

The Alpha port is mounted onto an isolator or restricted access barrier system (RABS) wall, and a Beta assembly must be securely mounted before the port door can be opened. Image Credit: Central Research Laboratories

What is a Beta assembly and what are their advantages and disadvantages?

Jim Peterson:

RTPs are used to avoid contamination issues by securely transferring materials from one isolation chamber to another without breach of containment. This helps protect both the transfer environment and the product.

Thanks to their design capabilities, RTPs are routinely used for material input or output or the removal of solid waste from isolation chambers during a manufacturing application. RTPs are available in five standard opening sizes: 105, 190, 270, 350 and 460 mm in diameter.

From food-grade autoclaving to ethylene oxide gamma sterilization and H2O2 sterilization, the RTP components are also manufactured from materials resistant to multiple sterilization procedures.

The Beta assembly, within RTP operation, is generally a removable stainless-steel or plastic container or plastic bag that contains the material that needs to be transferred into isolation. This Beta assembly plays a vital role in supporting these products' safe, sterile transfer.

What different types of Beta assemblies are offered by CRL?

Not all Beta assemblies are created equal. CRL provides a complete portfolio that can be relied upon in all material-transfer work.

- Standard Beta Canisters: These are principally used to transfer non-sterile or high-potency products requiring a gas-tight design.

- Autoclavable Beta Containers: These are usually used for the handling of sterile products that require moist steam to pass through the container to create a sterilized atmosphere

- Single-Use Beta Bags: These are chiefly used to transfer sterile products/parts/samples into or out of an aseptic operating environment, such as Petri dishes, waste material, stoppers/seals, etc. Single-Use Beta Bags are frequently used instead of multi-use steel or plastic Beta containers that must be cleaned and requalified before each subsequent use.

- Sterile Liquid Transfer Ports (SLTP): These transfer liquids.

- Alpha Sterilization Cover: These are used when it is necessary to have the Alpha doors open during the decontamination of the isolator. The sterilization cover works as a “dummy” Beta container during decontamination.

- Beta Bag Flange Assembly: These are used to attach tubing or Tyvek® liner bags for removal and intake operations; an operation which is similar to a Single-Use Beta Bag.

- Beta Flange with Tri-Clamp Fitting: These connect large tanks and process equipment to isolation.

- Inside Funnel Assembly: These protect the “Ring of Concern” – the term given to the point at which the Beta assembly connects with the Alpha port, which is a prime spot for contamination or leaks to occur unless the proper connection technology is being used – during the transfer of materials or tools.

- Inside Bagging Ring Assembly: This is a chute for dispensing with a liner bag.

- Beta Couplers: These are used to dock two isolators to one another, one of which is stationary and one of which is mobile.

Single-use systems, like the CRL Single-use Beta Bags, are a popular way to safely bring critical components into pharmaceutical fill lines. Image Credit: Central Research Laboratories

How do you assist clients when choosing between single-use and multiple-use systems?

Jeet Patil:

Each material-handling system is unique, and each has its specific product-transfer requirements and characterizations. The advances made in single-use systems have helped to spark their growing popularity in recent years.

At times, flexibility is needed for heavy cargo or Beta containers that cannot be safely rotated. Cases like these require custom solutions to ensure safe and reliable material transfer. Image Credit: Central Research Laboratories

Beta Bags are the foundation of these next-generation single-use systems. They can be disconnected from the isolation chamber, glovebox or cleanroom wall and disposed of when they are no longer required.

These features eliminate the need for cleaning, and requalification/revalidation operations after production can simultaneously facilitate the production process to meet all relevant regulatory-compliance parameters for purity and sterility.

Fully sterilized single-use beta bags will help facilitate the transfer of sterile components into isolation when used in conjunction with an Alpha port and facilitate the removal of any toxic components or waste that may be produced.

Though some operators may prefer multi-use systems in life science applications, and there is still a place for them, the advances in single-use technologies are underlining the inherent shortcomings of multi-use systems.

These drawbacks include the initial cost for equipment and installation and, as noted above, the time cost involved in the cleaning/revalidation and overall upkeep of steel or plastic Beta containers.

How is the use/development of transfer systems impacted by changing regulations?

Jeet Patil and Jim Peterson:

In any industry, the goal of any regulatory agency is to offer guidance and direction, which ultimately results in better manufacturing practices. Our goal is to produce manufacturing processes that improve product quality, enhance safety and avoid human errors while realizing that manufacturing operations vary from industry to industry, company to company, and person to person.

Expertise, time, and resources are required for navigating a complex regulatory landscape. Noncompliance can result in negative publicity, fines, penalties, and, in the worst-case scenario, the cessation of manufacturing operations.

For all operators in the life-science realm, this makes detailed knowledge of and adherence to all relevant regulatory regimes a priority.

The U.S. Food & Drug Administration (FDA) regulates the production of life-science products in the United States.

In this capacity, the FDA develops and distributes Current Good Manufacturing Practices (CGMP). The FDA can issue non-conformity notices to companies that fall out of compliance, potentially prohibiting finished pharmaceuticals from being sold to the public.

Yet another reason that manufacturers of equipment and systems – such as RTPs or Beta Bags – used to manufacture life science products must prioritize staying abreast of current regulations and regulatory developments is that the FDA actively develops and enforces new regulations related to CGMPs.

The FDA is widely regarded as a global leader in the development and the enforcement of regulations relevant to the life science arena. Many countries worldwide have adopted FDA rules as their own as a result.

The burden on manufacturers of life-science transfer systems to produce products compliant with global regulations can be partially lifted by uniform standards and requirements.

Equipment manufacturers and operators must also be aware that regulations are subject to a never-ending series of revisions and reviews within the life sciences. In 2022, for instance, the European Union revised its CGMP Annex 1, which governs the “Manufacture of Sterile Medicinal Products.”

This revision includes additional detail related to many of the requirements included in the prior version of Annex 1, released in 2008, along with new requirements. This change underlines how imperative it is that the manufacturers and users of transfer systems are up-to-date on the latest regulatory rules and requirements relevant to the products they sell.

To this end, CRL has always designed its technologies with the latest regulatory developments front and center. Operator safety and efficiency, along with product consistency, are promoted and optimized by our products.

CRL also works directly with its customers to identify the best solutions, from standard product offerings to customized development. This dedicated bespoke service helps to ensure the creation of the best solution possible for the safe and confident handling in every application need.

What is CRL’s background, and how does this background relate to the creation of CRL transfer systems?

Jim Peterson:

As World War II was concluding in the fall of 1945, three recent graduates of the Massachusetts Institute of Technology named Demetrius Jelatis, Frank G. Chesley and Gordon M. Lee decided to combine their resources and create a company they named Central Research Laboratories®, Inc., (CRL).

Since its founding in 1945, CRL has been a trusted industry partner and an important part of the Red Wing, Minnesota, USA, community. Image Credit: Central Research Laboratories

Their company began life as one that designed radar-testing equipment for use by the various branches of the U.S. armed forces, as a result of their undergraduate experience as researchers for the U.S. War Department.

CRL branched out into other areas of concentration from their beginnings in radar-testing equipment, and succeeded in developing safer methods of handling radioactive materials, which they subsequently supplied to the U.S. Atomic Energy Commission. Following their success in the field, CRL began narrowing its focus to designing, engineering and manufacturing remote-handling technologies.

CRL began developing systems for use in the life-science market as it continued to evolve and expand its product expertise, with 1997 bringing the development of the company’s first Rapid Transfer Port (RTP) technology.

This was a true watershed moment as CRL subsequently turned its attention to optimizing performance in life science product handling, as it continues to do today: with the latest innovation in its portfolio of Single-Use Beta Bags.

Its status has also helped CRL as a product brand within DESTACO, which is a developer of automation, workholding and containment solutions for industrial markets, as well as its role within the Dover Corporation, a diversified global solutions provider and manufacturer for five industrial operating segments.

This network has allowed CRL to find strength in further relationships with other life science-focused members of Dover’s Pumps & Process Solutions operating segment.

Key relationships are with the newly formed PSG Biotech®, which offers pumps and flow-monitoring/measurement/control systems for life science product production, and CPC®, a developer of connectors, quick-disconnect coupling and fittings for life-science applications.

At its core, CRL today remains committed to providing solutions that protect the operator environment when handling sterile/aseptic or hazardous materials.

How has the last decade changed CRL transfer systems?

Jim Peterson:

Over the last decade or two, CRL’s transfer systems have expanded in several exciting new directions. CRL has moved well beyond the static multi-user methods of yesterday to those that offer the user more variety and flexibility.

One of the most significant evolutionary innovations is the Single-Use Beta Bags, which eliminate the time-consuming and costly acquisition, cleaning/revalidating, outfitting, and upkeep needs that multi-use stainless-steel systems have.

CRL also offers a more robust portfolio of RTP technologies. One of the more significant recent innovations is our ERTP model.

Though the ERTP uses the same double-door transfer system as a typical RTP, it also includes a revolutionary new handle with minimal rotation to break the seal on a Beta container. This minimal rotation reduces operator effort and results in safer handling.

A streamlined interlock system is also featured in the ERTP, with interchangeable mounts that can be replaced without breaking containment.

Exposed fasteners are also eliminated by the new-and-improved design, and a smoother surface is incorporated for easier cleaning.

The ERTP family of Alpha ports is the latest innovation in improving performance while lowering costs and lead times. Image Credit: Central Research Laboratories

What is your vision for the future evolution of CRL transfer systems?

Jim Peterson:

Core parts of CRL's plans include continuing to invest in single-use systems, expanding our product line, and ultimately finding methods of making operating RTPs easier. These goals will be met without sacrificing important safety or product-containment qualities and will evolve with changing regulatory requirements. As our customers’ needs evolve, we can evolve with them.

To realize this plan for the future, CRL will continue to optimize the flexibility that allows us to move with the market. This can be accomplished simply by trying daily to offer a better solution for our customers' wants and needs.

CRL is and will always remain customer-intimate, with constant communication between customers and our team to see what is needed and then working on bringing what they need to market.

About Jim Peterson

A Sales Manager at Central Research Laboratories (CRL), Jim Peterson is responsible for the company’s sales efforts in both the Rapid Transfer Port (RTP) and Single-Use Beta Bag product categories for use within the life science market. Jim holds a Bachelor of Management Information Systems Degree from Augsburg University.

Jim joined CRL in 2019 with more than 20 years of managerial experience.

About Jeet Patil

-

Jeet Patil is a Sales Manager, Life Science at Central Research Laboratories (CRL). He has more than 20 years of experience in business development for the capital goods industry, specializing in the pharmaceutical, food manufacturing and packaging industries. He holds a bachelor of science in mechanical engineering from Maharashtra State Board of Technical Education with postgraduate certification in tool engineering.

Jeet’s sales manager experience began in 1994 as a product manager for ACG World. Since then, he has held sales roles with Fabtech Technologies International and Protech Group China before joining CRL in 2016.

This information has been sourced, reviewed and adapted from materials provided by CRL Solutions.

For more information on this source, please visit CRL.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.