X-Ray diffraction (XRD) represents a powerful analytical tool for identifying and quantifying crystalline phases in clinker analysis. Clinker is a critical intermediate product in the cement manufacturing process, and its composition, along with crystalline phases, significantly influences the final properties of the cement product.

XRD plays a prevalent role in analyzing clinker mineralogy, providing in-depth details on phase composition, crystalline structure, and morphology of the clinker phases. This information holds utmost importance for optimizing cement production processes, ensuring quality control, and facilitating product development.

This article highlights the advantages of employing XRD in clinker analysis and offers insights into the latest advancements in XRD technology for this specific application.

Figure 1. ARL X’TRA Companion diffraction system. Image Credit: Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers

Instrument

The Thermo Scientific™ ARL™ X’TRA Companion (Figure 1) represents a user-friendly and uncomplicated benchtop XRD system, ideal for process control and more advanced applications. The ARL X’TRA Companion uses a θ/θ goniometer (160 mm radius) in Bragg-Brentano geometry and a 600 W X-Ray source (Cu or Co).

The beam's radial and axial collimation is regulated by divergence and Soller slits, effectively reducing air scattering with a variable beam knife. An optional integrated water chiller is available.

With its state-of-the-art solid-state pixel detector (55 x 55 µm pitch), the ARL X’TRA Companion guarantees rapid data collection and one-click Rietveld quantification capabilities. This facilitates automated result transmission to a LIMS.

Experimental

A powdered (ball-milled) clinker underwent reflection measurements using an ARL X’TRA Companion with Cu Kα radiation (Ni filter).

To ascertain reproducibility according to ASTM C1365, the sample underwent 21 repetitions of 10 minutes each. Phase quantification utilized Profex¹ (BGMN algorithm) employing a fundamental parameters approach. Reference structures were selected following Aranda et al.'s research in 2012.²

Results

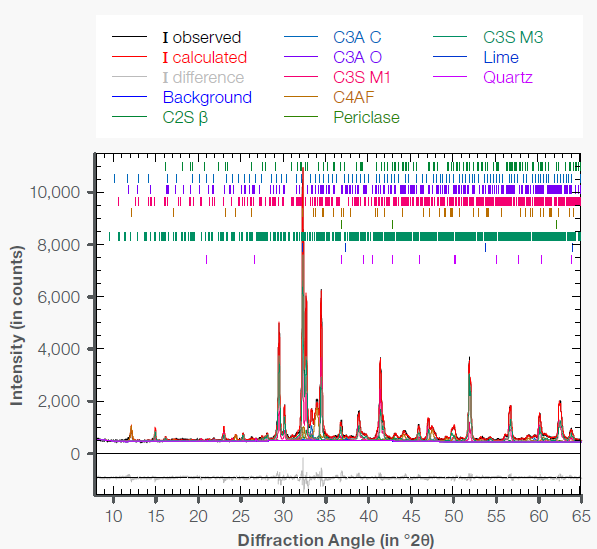

A clinker sample was analyzed for 21 x 10 minutes (see Figure 2), and subsequently, a Rietveld fit was conducted using a fundamental parameter approach.

By comparing the standard deviations obtained from the repetitive refinements (see Table 1) with the limits provided by ASTM C1365, it is evident that the results are in excellent agreement with the norm when considering the C3A total and C3S total.

Figure 2. Rietveld fit of clinker (10 min acquisition). Image Credit: Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers

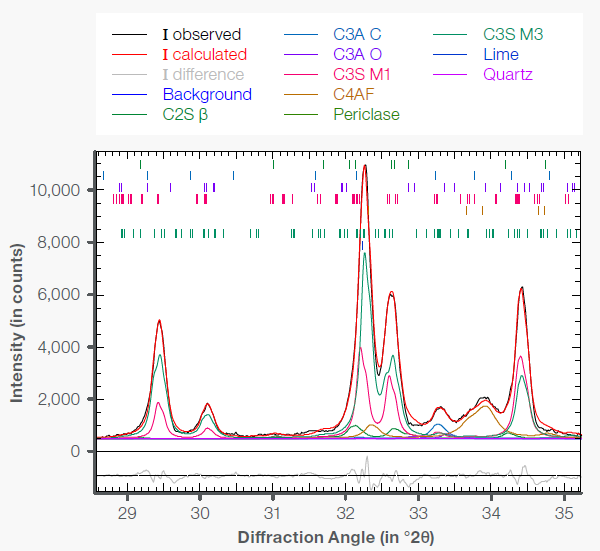

Figure 3. Rietveld fit of clinker (29-35° 2θ). Image Credit: Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers

The fingerprint region in the data demonstrates the clear identification of the main clinker phases (see Figure 3).

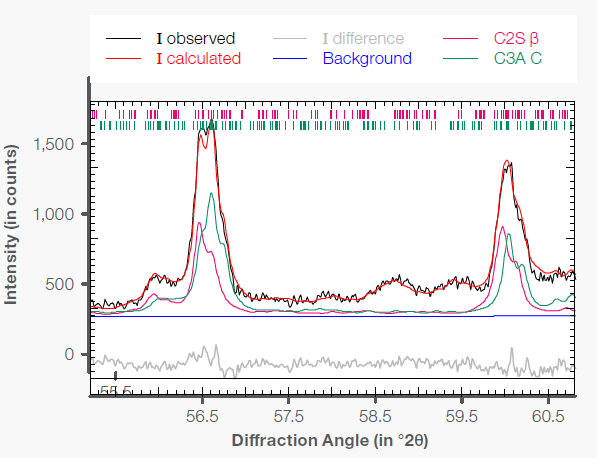

The analysis did not detect any amorphous content in the sample. Moreover, the sample contains C3S M1 and M3 modifications, which were accounted for during quantification. For this particular sample, achieving a standard deviation (1 σ) of 1% for C3S M1 and M3 is attainable (see Figure 4 and Table 1).

Table 1. Results of 21 consecutive refinements of clinker (values in weight percent). Source: Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers

| |

Average values |

STDEV |

ASTM |

| |

(in %) |

(1 σ in %) |

C1365 |

| C3S M1 |

30.81 |

1.08 |

|

| C3S M3 |

46.32 |

1.08 |

|

| C3S Total |

77.13 |

0.25 |

0.74 |

| C4AF |

12.08 |

0.20 |

0.64 |

| C2S β |

6.09 |

0.18 |

0.49 |

| C3A Cubic |

2.57 |

0.34 |

|

| C3A Ortho |

1.23 |

0.39 |

|

| C3A Total |

3.80 |

0.14 |

0.47 |

| Lime |

0.21 |

0.06 |

|

| Periclase |

0.59 |

0.06 |

0.23 |

| Quartz |

0.10 |

0.03 |

|

Figure 4. Measurement of clinker (55-61° 2θ); fit for C3S M1 (purple) and C3S M3 (green) explains intensity and shape of the reflections well. Image Credit: Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers

Conclusion

The ARL X’TRA Companion XRD provides data that complies with ASTM C1365 norms for analyzing clinker samples.

The one-click Rietveld refinement, based on a fundamental parameter approach, proves to be an extremely robust method with high reproducibility, delivering accurate results even for C3S M1 and M3. These exceptional qualities make the ARL X’TRA Companion the perfect solution for any process control task in the cement industry.

References

- N. Döbelin, R. Kleeberg, J. Appl. Crystallogr. 2015, 48, 1573-1580.

- M.A.G. Aranda, A.G. De la Torre, L. León-Reina, Rev. Mineral. Geochem. 2012, 74, 169-209.

This information has been sourced, reviewed and adapted from materials provided by Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers.

For more information on this source, please visit Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers.