Sponsored by Metrohm AGReviewed by Olivia FrostAug 22 2023

Raw material identification and verification (RMID) is a very complicated procedure for a very important reason: it affirms the caliber of raw materials employed in fabricating items destined for use within and on the human body.

The intricacy of RMID spans the spectrum from analytical methodologies and instruments to the testing protocol. It extends to encompass governmental regulations and standards that govern all facets of RMID, including system suitability, sampling extent, method validation, and electronic records, among others.

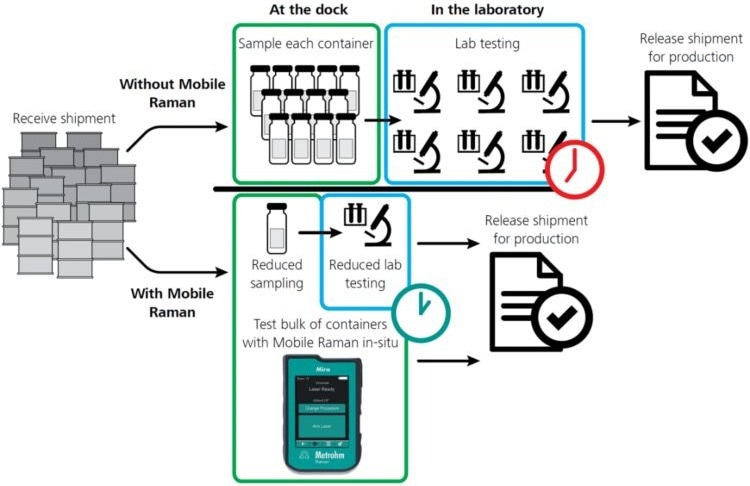

Warehouse verification of incoming materials in regulated industries, using mobile Raman technology, entails conducting RMID directly at the loading bay. Consequently, chemical analyses that were traditionally done in laboratories by trained chemists can now be done very quickly and with great success by non-specialized professionals.

With MIRA P and Mira Cal P, Metrohm Raman simplifies RMID. Image Credit: Metrohm AG

System Suitability

Image Credit: Metrohm AG

Manufacturers of handheld Raman devices for RMID must have suitable calibration and validation procedures in place.

Calibration of MIRA P with the Calibrate/Verify Accessory (CVA) accomplishes instrument calibration as well as system and performance verification. These tests are then summarized in the System Suitability Test (SST) report for MIRA P.

CVA ensures that MIRA P performs as intended and that users can trust the generated data quality. Following the SST, users can be confident that all measurements adhere to established standards.

Sampling Flexibility

RMID methods need to account for several factors to formulate the most precise and resilient solution for the task at hand. Special attention must be given to the following:

- The sampling strategy: How to gather the highest quality data under specific conditions.

- Sample presentation: Encompassing morphology, packaging, and chemical composition.

Handheld Raman is recognized as a particularly well-suited technique for RMID, as it offers a portable, onsite, no-contact analysis of solid and liquid samples.

Image Credit: Metrohm AG

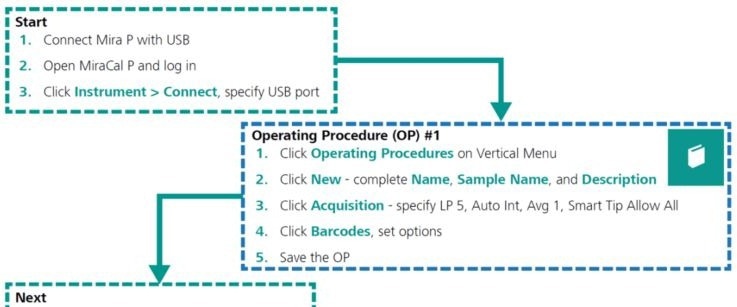

Method Development

From constructing Training and Validation Sets, along with targeted recommendations for acquiring the highest quality spectra, to specialized software routines that automatically ascertain optimal model parameters, MIRA P streamlines the creation of methodologies for RMID using handheld Raman.

Image Credit: Metrohm AG

The successful formulation of a methodology hinges on the incorporation of spectra into libraries and training sets designated for RMID. Thoughtful planning during the model design phase paves the way for a straightforward data collection stage.

This data can then be used to establish the most suitable model parameters for robust methodology development. With the assistance of Mira Cal P and ModelExpert, even individuals without extensive technical expertise can implement precise and efficient RMID methods.

Method Implementation

Integrating handheld Raman into RMID, where most materials testing occurs in the receiving area, represents a logical progression for this robust technique. It has gained widespread adoption owing to its substantial benefits.

Image Credit: Metrohm AG

- Massive time savings: With acquisition times of under a minute and immediate, evident outcomes, it allows for highly efficient throughput.

- Faster turnaround: Facilitates quicker delivery of materials to production.

- Reduced resources: Reduces the need for laboratory and warehouse personnel, as well as the consumption of lab supplies, leading to reduced costs and workloads.

- Guided Workflows: MIRA P features predefined workflows that simplify and enhance the sampling process.

With Full Compliance and Utter Confidence

Just as MIRA P has built-in routines to ensure instrument integrity, Mira Cal P is tailored to protect customer data integrity and facilitate adherence to global norms and standards. All RMID clients necessitate comprehensive, coherent, and precise data, and Mira Cal P surpasses these requirements by offering complete transparency and traceability.

Image Credit: Metrohm AG

Mira Cal P analytical software, developed by Metrohm Raman, instills peace of mind, guaranteeing meticulous adherence to multiple standards throughout the data processing phase.

Acknowledgments

Produced from materials originally authored by Dr. Melissa Gelwicks, Metrohm Raman, Laramie, Wyoming (USA).

This information has been sourced, reviewed and adapted from materials provided by B&W Tek.

For more information on this source, please visit B&W Tek.