In this interview, AZoM speaks to LECO's Andrew Storey about glow discharge spectrometry and the opportunities offered by LECO's GDS950.

What does glow discharge spectroscopy entail, and how does it fit into the realms of surface analysis and atomic spectroscopy?

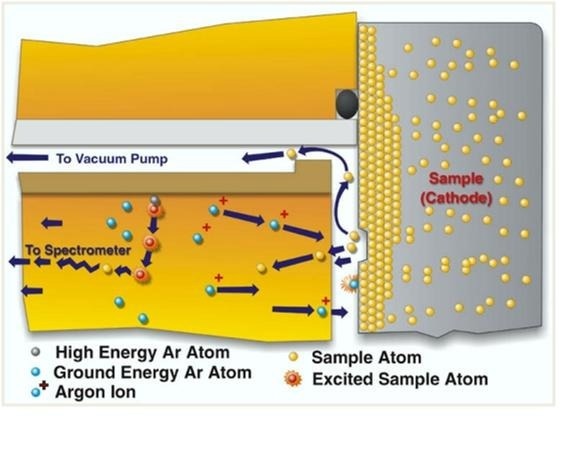

Glow Discharge Spectrometry (GDS) involves uniformly removing materials from a surface by sputtering them away in an argon plasma, exciting the removed atoms, and then capturing their emitted light through optical spectroscopy. Due to the source's even material removal and our extensive library of sputter rates, we can plot the removal of material over time and the emission of light effectively in a quantitative depth versus concentration plot.

Operationally, this process is quite simple, and the data reporting is relatively straightforward compared to other surface analysis techniques. Technicians and advanced researchers alike utilize this method. It falls into the realm of direct solid surface analysis within atomic spectroscopy.

Consider various sample types: While liquid solutions are easily analyzed using inductively coupled plasmas, GDS is a direct sampling technique. No digestion is required, simplifying the process for users of different backgrounds, eliminating the need for advanced sample preparation upfront, and providing high-quality data. Importantly, it does not destroy the sample beforehand. Analyzing samples in their original form is advantageous, preserving their unique characteristics.

How does the GDS950 revolutionize how researchers approach materials analysis, overcoming previous barriers to adoption?

There were a variety of impediments in past generations of Glow Discharge instruments. However, there is an excellent set of research out there, and we have had great success with our customers implementing Glow Discharge Spectroscopy in manufacturing applications.

However, for the depth profiling capabilities specifically, and in research environments, fixed characteristics made it great one day and problematic the next when operating the same unit for different projects. A great example is utilizing point detectors and photomultiplier tubes for individual elements to build a unit custom for a user. However, they had to decide on every aspect that they might want to characterize throughout the life of that unit, which in some cases is as long as 20 years after the unit is shipped to them.

Today's unit utilizes an array of CCDs, giving us full spectral coverage from 120 nanometers to 460 or 850 nanometers. It also uses a lamp that can use both DC and RF power. We can have non-conductive samples best analyzed with RF power and conductive samples ideally analyzed with DC power on the same lamp.

We needed to make hardware changes in between to switch between those in the past. We have stepped away from this kind of fixed structure and built an integrated convertible lamp that, through software changes alone, we can use both RF and DC power side by side. Again, it is a powerful new approach that steps away from those historic limitations.

Could you share a real-world scenario where the universal lamp feature of the GDS950 has significantly streamlined the sample analysis process?

This is a situation where we need to listen to our customers when designing the next generation of units. We worked with many labs that had their DC and RF lamp days, where maybe one day a week was dedicated to the RF lamp, while the DC lamp was in use the rest of the week.

However, this resulted in a backlog of samples and, consequently, a lack of data for those samples, whether over a day or a week. As a result, our customers had to decide which lamp to utilize on a given day rather than having all the capabilities of a powerful unit available to them at all times.

Some materials are better analyzed using the DC method because it allows for direct and immediate application, while others require the RF method. We have found that the best approach is to make both options immediately available to customers at all times for easy use in the laboratory.

Image Credit: LECO Corporation

In what ways does the GDS950's extended spectral data range transform the decision-making process for selecting spectral lines during analysis?

In the past, we worked with customers to select optimal spectral lines for their before shipment. While we might have had a couple of different lines for various elements, adding multiple lines increased costs and reduced the number of other elements available on those previous systems that required PMTs.

With the GDS950, we can choose lines based on what is best for an individual method, and customers can also make those choices later. There are many reasons you might select a spectral line. It might be because that line has exceptional intensity characteristics at low concentrations. It might be that it exhibits excellent linearity at higher concentrations. You might encounter many interferences in one material and none in another. In one sample, it might serve as a matrix element, while in another, it might function as a trace. These different situations could lead to the selection of different spectral lines.

Previously, you had to choose a spectral line or two that performed all of these functions as best as possible rather than selecting the line that best suited the application.

This new approach opens up even greater linearity ranges for our customers. It has also broadened our perspectives on what is achievable with this technique in constructing methods delivered to our customers turnkey.

Our customers do not have to search for every line that meets their requirements; that work is being conducted here at LECO, and we take great pride in the accomplishments made in this area and the benefits our customers derive from it.

Can you explain the significance of the GDS950's ability to accommodate future calibration changes and integrate new elements into methods?

We ship with previously developed methods, which provide our customers with a great starting point for their work. During the sales process, we collaborate with them to create an instrument that best suits their needs. Inevitably, the need for a new element may arise after a unit is installed in a research setting.

What makes the GDS950 truly exceptional is that all calibration data for the various standards used in calibration, potentially involving several dozen standards in a depth profiling method, remains accessible to the user across the entire spectral range. Therefore, if there is a requirement to include strontium in a calibration, and there are 10 standards that contain strontium, even if they were not initially activated, you can incorporate them into your process and access multiple relevant lines with substantial calibrations.

It is essential to note that a wealth of information is readily available to activate these capabilities, and no hardware modifications are necessary. LECO's experienced GDS team is ready to support our customer's changing needs. Even in cases where software expansion might be required, much of this can be accomplished remotely over the phone or through a simple service visit, eliminating the need for extensive instrument surgery.

How does introducing drag-and-drop calculations in the GDS950 empower researchers to tailor their analysis for unique applications?

In our depth profiling methods, we generally have defined calculations, such as the thickness of a layer, a coating weight, and maybe the width of an transition region that defines how tight an interface is between two materials.

Many of these calculations will come with a turnkey method, but we do not know everything that our customers will do in the future, and neither do they. We do not expect our customers to tell us what their next 20 years of the research will look like, so those same types of calculations might need to be modified over time.

Instead of building a syntax-based approach, we have created a drag-and-drop system where you can pull the calculations straight into parentheses. Then, if you want a coating weight, it just says, "Coating weight for this element (or compound)" and you can establish a start and endpoint for that measurement.

This is more user-friendly for most of our users than the syntactic approach used in the past that required mild degree of programming ability.

Image Credit: LECO Corporation

The GDS950 is designed to serve both research and manufacturing needs. Could you provide an example of how this adaptability benefits users in different contexts?

Thinking about an automotive OEM is an excellent way of understanding this. At an automotive company, you could have an engine plant that requires bulk characterization of many incoming materials. You could have a stamping facility that applies a coating, whether galvanized or aluminized, to a surface, and then, of course, you have the next generation of vehicles that could have all kinds of new coatings at the research center.

If you take those three steps, they all require different methodologies, but they can also be developed and simulated at that research center before implementation in a production environment.

This comprehensive approach demonstrates the compatibility of routine analysis and research and the adaptability of the GDS900 and 950 series of instruments; the same type of unit can be configured for each of these environments as appropriate.

In what ways does the GDS950's comprehensive spectral range enhance the depth of understanding that researchers can gain from materials analysis? Have you encountered a situation where the GDS950's flexibility was decisive in optimizing the research process?

If we examine atomic spectroscopy, there are instances where different spectral lines are chosen. The spectral lines for Glow Discharge Spectroscopy differ from those optimal for inductively coupled plasma. The spectrometer offers substantial flexibility for atomic spectroscopy researchers interested in spectral characteristics and behavior, and the software is designed to accommodate this.

I believe most customers may not delve deeply into these intricacies, but a few will. However, it does present an opportunity for LECO's team to collaborate with our customers to enhance methodologies in this regard. It is not only our customers who will be working with these units in the future, it is also the comprehensive support team that LECO can provide who continually strive to provide improved techniques for our customers.

Can you discuss the role of the GDS950 in bridging the gap between traditional expert-intensive approaches and more user-friendly, efficient methodologies?

I would describe most surface analysis techniques as expert-intensive. When you walk into a conventional surface analysis lab, you will encounter instruments like secondary ion mass spectrometers, Auger electron spectrometers, or X-ray photoelectron spectrometers that demand significant expertise to operate effectively. In general, this means individuals who have dedicated years to mastering these instruments and their applications.

With the Glow Discharge Spectrometer, we feel confident that even with the training we provide at installation, most users can achieve high-quality surface analysis almost immediately.

We offer additional training to our customers, but it does not necessitate having a dedicated, expert user for this unit, as is often the case with many other surface analysis techniques. In fact, we have entry-level technicians running these units and reliably acquiring data for depth profiling applications.

We also have excellent researchers obtaining fascinating new data on novel materials. This unit is designed to accommodate these diverse user profiles without requiring dedicated maintenance or analysis experts for each unit.

About the speaker

Andrew P. Storey, PhD is currently LECO’s field sales specialist for glow discharge spectroscopy. In this role, he works with LECO’s North American team to develop specialized solutions for customer needs for advanced metallurgical and elemental analyses. He completed his Ph.D. degree in analytical chemistry at Indiana University-Bloomington, where he focused on the application of several different glow discharge sources for novel analyses. Dr. Storey has authored and co-authored 9 peer-reviewed papers in the field, presented at more than 20 conferences, and has collaborated closely with leading atomic spectroscopy experts from around the world. His early career included work with organic mass spectrometry for clinical and environmental applications.

This information has been sourced, reviewed and adapted from materials provided by LECO Corporation.

For more information on this source, please visit LECO Corporation.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.