From AvantesReviewed by Emily MageeOct 25 2023

In this interview, AZoM speaks with Ger Loop, Product Manager at Avantes, about Avantes' impressive 30 years of spectroscopy experience, their mission, and the future of their product lines.

Can you provide an overview of Avantes’ mission and how it aligns with the development of next-generation spectroscopy technology?

Avantes' mission is to provide state-of-the-art, innovative measuring equipment that contributes to improving human health and preserving our planet for future generations. This commitment drives us to continually enhance our spectrometer offerings, ensuring reliable and reproducible results for our customers who integrate our technology into their products.

We also strive to introduce new spectrometer models that enable the realization of emerging applications. This involves miniaturization while maintaining exceptional optical performance to meet the rigorous standards set by our customers.

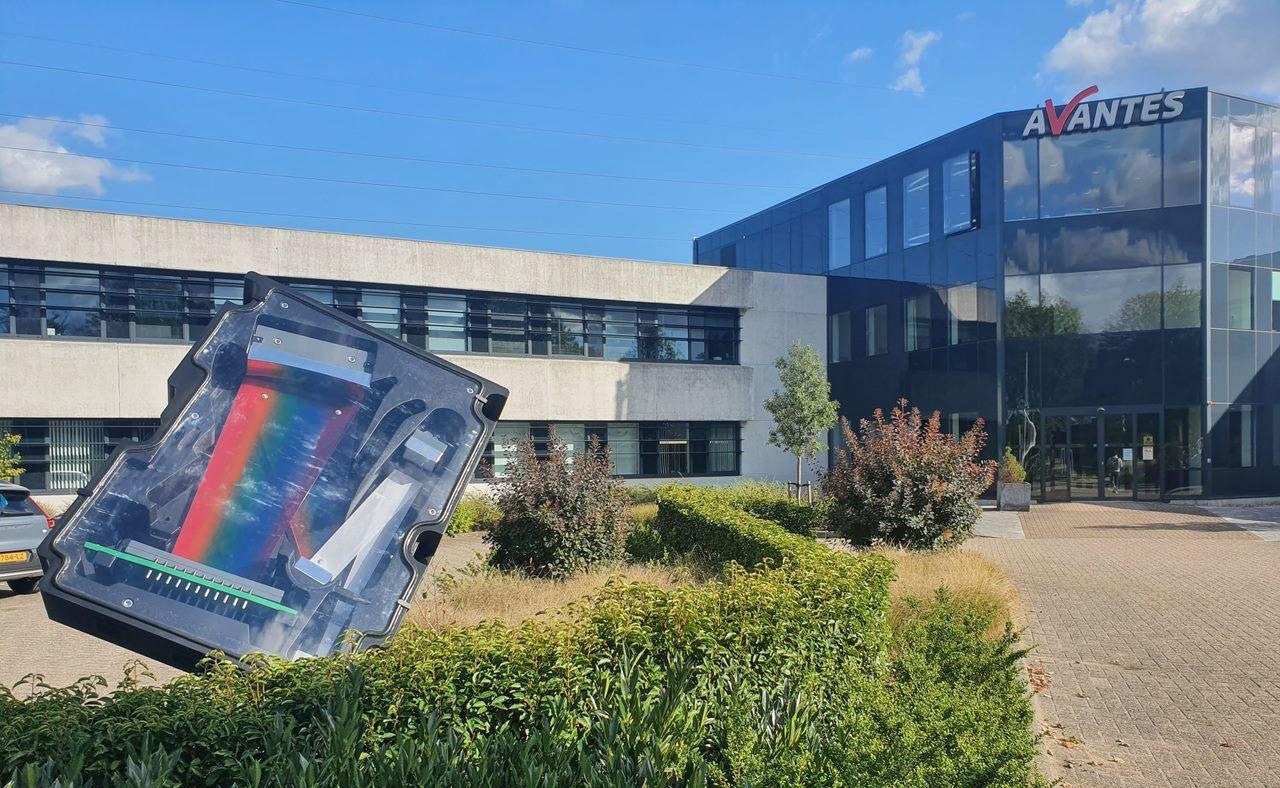

Image Credit: Avantes

Avantes has nearly 30 years of experience in fiber-optic spectroscopy. How has this extensive experience influenced the company’s ability to push the boundaries of what is possible in spectroscopy?

Avantes' extensive history in fiber-optic spectroscopy has been instrumental in our ability to drive innovation in this field. Over the years, we have engaged with researchers seeking to unlock new applications, gaining insights into industry trends and potential areas for improvement. This ongoing interaction with the scientific community has continuously informed and inspired us to enhance our product offerings.

Avantes’ automated production process plays a crucial role in ensuring the reproducibility and scalability of its spectrometers. Can you provide an overview of how this automated process is utilized to manufacture Avantes’ products effectively?

Our automated production process is a crucial factor in our ability to deliver high-quality spectrometers to our customers consistently. Through automation, we achieve precision and efficiency in various stages of manufacturing. Here's a brief overview of what this process contributes:

Precision Assembly: Automation is employed to assemble critical components with unparalleled precision. This ensures that every Avantes spectrometer meets our quality standards and performs reliably.

Quality Control: Automated quality control measures are implemented at multiple checkpoints throughout the manufacturing process. These measures include testing and calibration, guaranteeing that each spectrometer meets our specifications.

Scalability: Automation allows us to scale our production in response to customer demand. Whether we are producing a single unit or a large batch, our automated systems ensure consistent quality and reproducibility.

Data collection: Automation also facilitates traceability, enabling us to monitor and document every step of the manufacturing process. With the help of all the data collected, we can continuously improve the process.

In summary, Avantes leverages advanced automation to manufacture spectrometers effectively, ensuring both reproducibility and scalability. This commitment to automation is a key factor in our ability to provide reliable and high-performance spectrometers to our customers.

Can you provide an overview of some recent innovations in Avantes’ product line and how these advancements contribute to Avantes’ position as a leader in advancing spectroscopy technology?

While we cannot go into specific details, our latest compact spectrometer has significantly improved optical performance. These enhancements result from modifications in the optical path and the introduction of a patent-pending technology. This innovation allows us to control the sensitivity of the spectrometer without compromising resolution.

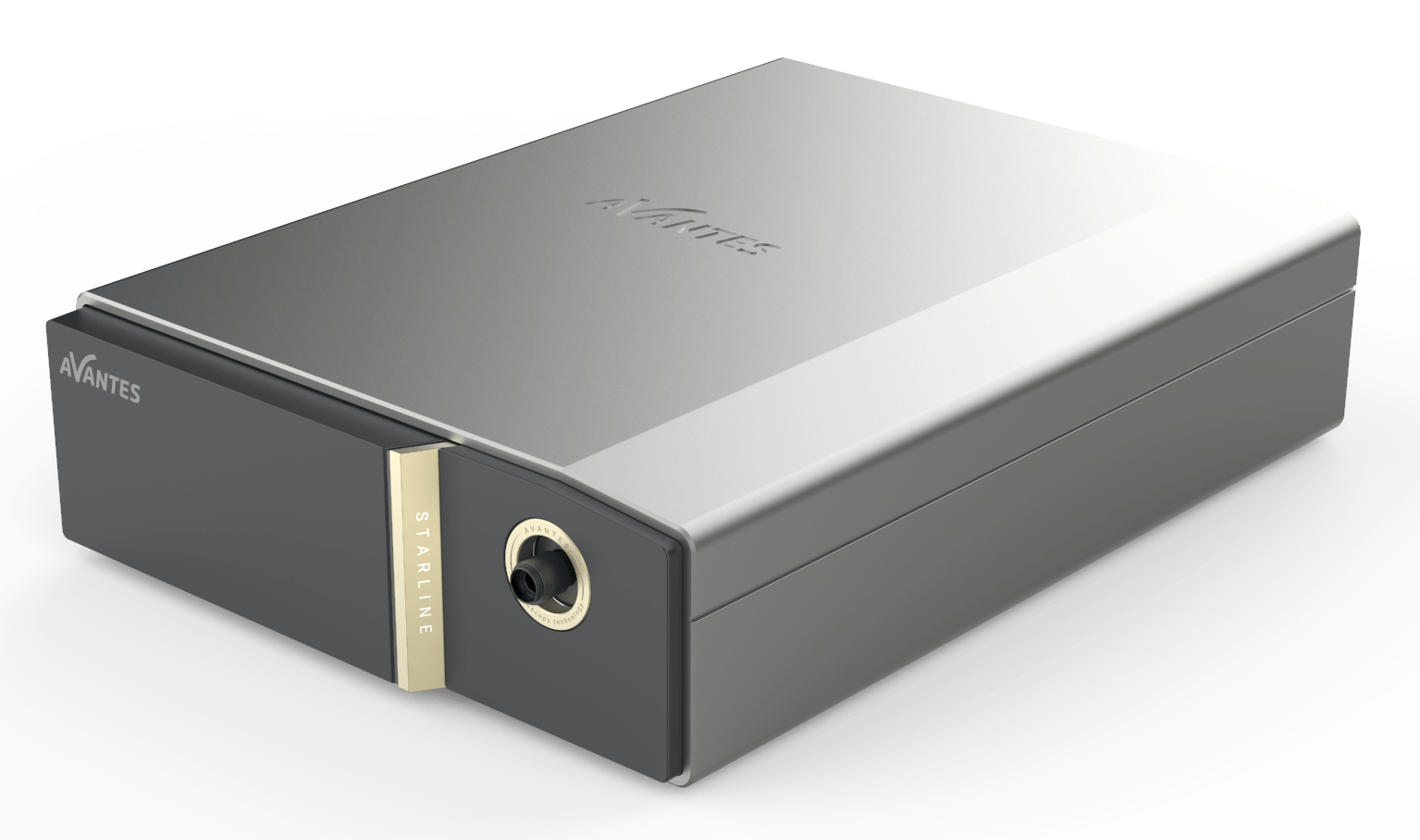

Image Credit: Avantes

Can you elaborate on the versatile applications of Avantes’ replaceable slit feature and its significance in the product range offered by Avantes?

The replaceable slit feature plays a pivotal role in our product range. In the field of spectrometry, requirements can often be fluid, and there is a constant trade-off between sensitivity and resolution. Avantes' replaceable slit option empowers users to modify the spectrometer's functionality in the field, eliminating the need for additional spectrometers or time-consuming returns for rework. This flexibility saves time and resources, particularly during the exploratory stages of development or when the instrument is utilized for diverse research purposes.

Avantes emphasizes achieving outstanding stray light performance and a strong signal-to-noise ratio in its spectrometer products. Could you explain how these critical parameters are prioritized in product development?

Stray light and signal-to-noise ratio are critical factors in compact spectroscopy. Stray light can introduce inaccuracies in readings, which is a concern for us. Therefore, we continuously work to understand and mitigate stray light in our spectrometers, ensuring trustworthy output.

Similarly, a good signal-to-noise ratio is essential for our customers to push the boundaries of their analyses. Our choice of detectors and electronics design are vital in achieving this, making them fundamental aspects of our product development.

Avantes enables measurements in various wavelengths, from chemical composition to color measurement. Can you elaborate on how this versatility in wavelength range is reshaping spectroscopy applications across industries?

Spectrometry's adoption in diverse industries is largely due to the versatility it offers. Each application demands specific wavelength ranges, sensitivity levels, resolutions, triggering capabilities, and speed. Although I would love to take credit for these advancements, they belong to our customers who explore new frontiers and find solutions that enhance the value of our instruments. Avantes responds by closely listening to their needs and providing a range of high-quality instruments that can be customized and fine-tuned as required to meet their unique demands.

Image Credit: TorPias/Shutterstock.com

Avantes offers a variety of software packages as well. Can you describe the user experience when operating Avantes’ spectrometers and navigating the software interfaces?

The different software packages we offer enable the customer to pick a package that matches their needs the best. We aim to create an intuitive experience for our customers with our AvaSoft software. The interfaces are designed with user-friendliness in mind. They feature intuitive layouts and straightforward navigation, ensuring that users can quickly access and utilize the spectrometer's capabilities without a steep learning curve.

Besides that, our software is designed to be compatible with a variety of operating systems, making it accessible to a broad user base. Whether you are using Windows, macOS, or Linux, you can seamlessly integrate our spectrometers into your workflow. If none of these options match the needs of the customer, we offer the option to write customized software with our DLL (Dynamic Link Library) packages.

In conclusion, we can say that the various packages we offer, combined with user-friendly design, ensure that our users have the tools they need to achieve their objectives with ease and efficiency.

Avantes’ products have a significant presence in the spectroscopy community. How is Avantes fostering collaboration and knowledge exchange among users of its technology?

Avantes maintains close relationships with our customers and distributor network. We actively gather knowledge from our customers and share it through global training initiatives, empowering our sales teams to better assist their clients. Our application engineers consolidate application expertise into accessible resources, enabling both our organization and customers to benefit from this knowledge when needed.

Can you share a few examples of how Avantes’ latest product, the Varius Spectrometer, is being used across different industries to give our audience a sense of its versatility?

Being our next-generation Starline product, we already know, based on the success of its predecessors, that the Varius can be used in a wide variety of applications. Ranging from color analysis for quality control near production lines to radiometric measurements in the lighting industry and from being part of a LIBS system to analyze the plasma for recycling purposed to a generic research tool in the laboratory. Its adaptability makes it a valuable asset in a wide range of applications.

Avantes Varius Spectrometer | When Versatility Meets Precision

Video Credit: Avantes

The upcoming webinar promises insights into how Avantes’ Varius Spectrometer will impact applications, research, and businesses. Could you share a teaser of what participants will gain from attending the webinar?

Our webinar aims to introduce our latest spectrometer, the Varius Spectrometer, to the world. We will provide an understanding of its features and capabilities, positioning it in relation to our existing product offerings. Attendees will gain insights into the instrument's versatility and how it can potentially benefit their spectroscopy applications, research, and business.

About Ger Loop

Ger Loop completed his Bachelor's degree in Electronics and has worked in the electro-optical field in several technical roles. He joined Avantes in 2009 and has been a product manager since 2014. He works closely with customers and their applications, ensuring that the Avantes products range optimally meets their needs.

This information has been sourced, reviewed and adapted from materials provided by Avantes BV.

For more information on this source, please visit Avantes BV.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.