In the ever-evolving landscape of technological innovation, the combination of precision engineering and additive manufacturing has given rise to a revolutionary concept: microscale 3D printing. This cutting-edge technique has unlocked a realm of possibilities, enabling the creation of intricate and minuscule structures that hold immense potential for fields like microfluidics and electronics.

In this article, we discuss what microscale 3D printing is, its role in microfluidics and electronics, and round up the challenges and prospects of the technology.

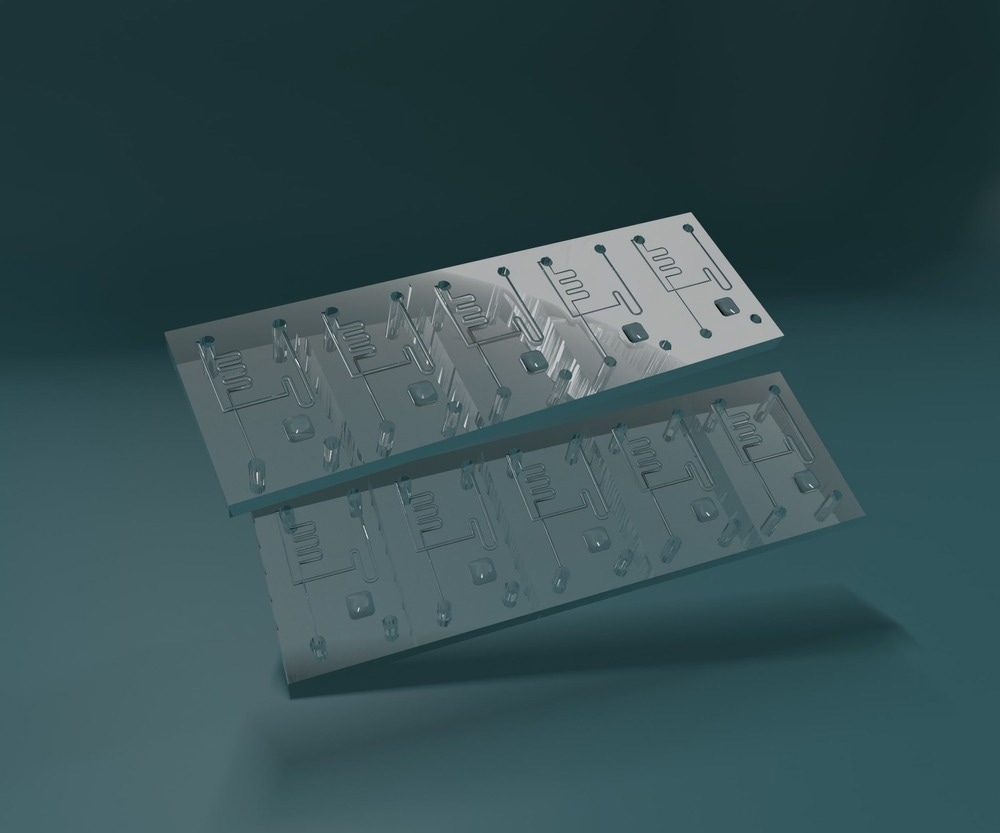

Image Credit: Love Employee/Shutterstock.com

The Rise of Microscale 3D Printing

At its core, microscale 3D printing is a fabrication process that constructs three-dimensional objects on a scale of micrometers. Unlike traditional 3D printing that caters to larger structures, microscale 3D printing operates at the micro-level, offering unparalleled precision and control.

This technology leverages a variety of materials, including polymers, metals, ceramics, and even living cells, to build intricate structures layer by layer. The result is an astonishing level of detail and complexity, achieved through a process that was once considered the realm of science fiction.

How Microscale 3D Printing is Revolutionizing Microfluidics

Microfluidics, the study of fluid behavior at the microscale, has found a natural ally in microscale 3D printing. The ability to create intricate microchannels, chambers, and valves at such a tiny scale opens a realm of possibilities for applications ranging from medical diagnostics to chemical analysis.

Traditional microfluidic devices were often painstakingly fabricated using complex lithography processes, limiting their complexity and customization.

Microscale 3D printing offers the flexibility to design and produce microfluidic systems with unprecedented intricacy and efficiency. Some examples of these systems include;

Lab-on-a-Chip Devices: Microscale 3D printing allows for the creation of miniaturized lab-on-a-chip devices, which integrate multiple laboratory functions onto a single microchip. These devices have applications in various fields, including biomedical diagnostics, environmental monitoring, and drug discovery.

Microreactors: Microscale 3D printing enables the fabrication of microreactors, which are used for chemical synthesis, analysis, and screening at the microscale. These miniaturized reactors offer advantages such as improved reaction efficiency, reduced reagent consumption, and enhanced control over reaction conditions.

Microscale 3D printing allows for the creation of custom microchannels and reaction chambers, facilitating precise control over fluid flow and chemical reactions. This level of customization and control is a game-changer in the field, allowing researchers to develop highly sensitive and specific diagnostic tools.

Microscale 3D Printing Empowers Electronics and Beyond

The electronics industry, a realm perpetually in pursuit of smaller and more powerful devices, is also reaping the benefits of microscale 3D printing. Traditional manufacturing techniques face inherent limitations when it comes to miniaturization, often resulting in compromised performance or increased complexity.

Microscale 3D printing sidesteps these issues, offering the capability to create intricate electronic components and interconnects with minimal size constraints.

Printed microscale electronics are finding applications in areas such as wearable devices, implantable medical sensors, and even aerospace technology. The precision afforded by microscale 3D printing allows for the production of densely packed circuits and antennas, enabling devices that are not only smaller but also more efficient and capable.

Furthermore, this technology enables the integration of multiple materials in a single structure, paving the way for multifunctional electronics that can perform a variety of tasks on a microscopic scale.

Miniaturized Circuitry: microscale 3D printing allows for the creation of intricate circuitry with high precision, enabling the production of miniaturized electronic devices. This technology has the potential to revolutionize the development of wearable electronics, implantable medical devices, and sensors.

Customized Components: Microscale 3D printing offers the ability to fabricate customized electronic components, such as antennas, connectors, and housings. This customization capability allows for the production of tailored solutions that meet specific design requirements and performance criteria.

Challenges with microscale 3D printing and Future Prospects

As with any groundbreaking technology, microscale 3D printing comes with its own set of challenges. Achieving high-resolution prints at the microscale requires precise control over printing parameters and materials. Additionally, the delicate nature of microscale structures demands a careful balance between structural integrity and material properties.

Researchers are continuously working to refine printing techniques and develop new materials that are optimized for microscale applications.

Looking ahead, the future of microscale 3D printing appears promising. Microscale 3D printing is a rapidly evolving field with immense potential for further advancements. Researchers and engineers are continuously exploring new materials, techniques, and applications to push the boundaries of this technology.

Areas currently under exploration and advancement encompass:

Multi-Material Printing: Microscale 3D printing techniques can be used to deposit multiple materials in a single print, opening possibilities for creating complex, multi-functional structures.

Biofabrication: microscale 3D printing is being utilized in the field of biofabrication to create intricate scaffolds for tissue engineering and regenerative medicine applications, enabling the production of patient-specific implants and organs.

Integration with Other Technologies: Microscale 3D printing can be combined with other technologies, such as microfluidics and nanotechnology, to create integrated systems with enhanced functionalities. These have applications in biosensors, micro-optics, and microelectromechanical systems.

Conclusions

Microscale 3D printing stands as a testament to human ingenuity and technological prowess. With its ability to create miniature structures of exceptional intricacy and precision, this technology is reshaping the landscape of microfluidics and electronics. From facilitating rapid medical diagnostics to powering next-generation wearable devices, the impact of microscale 3D printing is far-reaching and transformative.

As researchers and engineers continue to improve the microscale 3D printing technology, we can only imagine the remarkable breakthroughs that lie ahead, ushering in an era of unparalleled miniaturization, customization, and efficiency.

The Global 3D Printing Market - Growth, Trends, and Applications

References and Further Reading

All3DP Pro, (2022). Micro 3D Printing – The Ultimate Guide [Online]. All3DP Pro. URL https://all3dp.com/1/micro-3d-printing-guide/ (accessed 8.14.23).

Makenica, (2023). Microscale 3D Printing: Miniature Solution for Big Challenge. Makenica.com. URL https://makenica.com/microscale-3d-printing/ (accessed 8.14.23).

Network, M.C. (2022). What is microscale 3D printing? Lessons learned from Mayo Clinic [Online]. Medical Design and Outsourcing. URL https://www.medicaldesignandoutsourcing.com/what-is-microscale-3d-printing-mayo-clinic-microfabrication-lab/ (accessed 8.14.23).

O’Neill, B. (2022). Micro 3D printers and micro AM [Online]. Aniwaa. URL https://www.aniwaa.com/buyers-guide/3d-printers/micro-3d-printers-micro-am/ (accessed 8.14.23).

Park, Y.-G., Yun, I., Chung, W.G., Park, W., Lee, D.H., Park, J.-U. (2022). High-Resolution 3D Printing for Electronics. Advanced Science 9, 2104623. https://doi.org/10.1002/advs.202104623

S, C. (2023). The Best Micro 3D Printing Solutions On the Market [Online]. 3Dnatives. URL https://www.3dnatives.com/en/the-best-micro-3d-printing-solutions-19012023/ (accessed 8.14.23).

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.