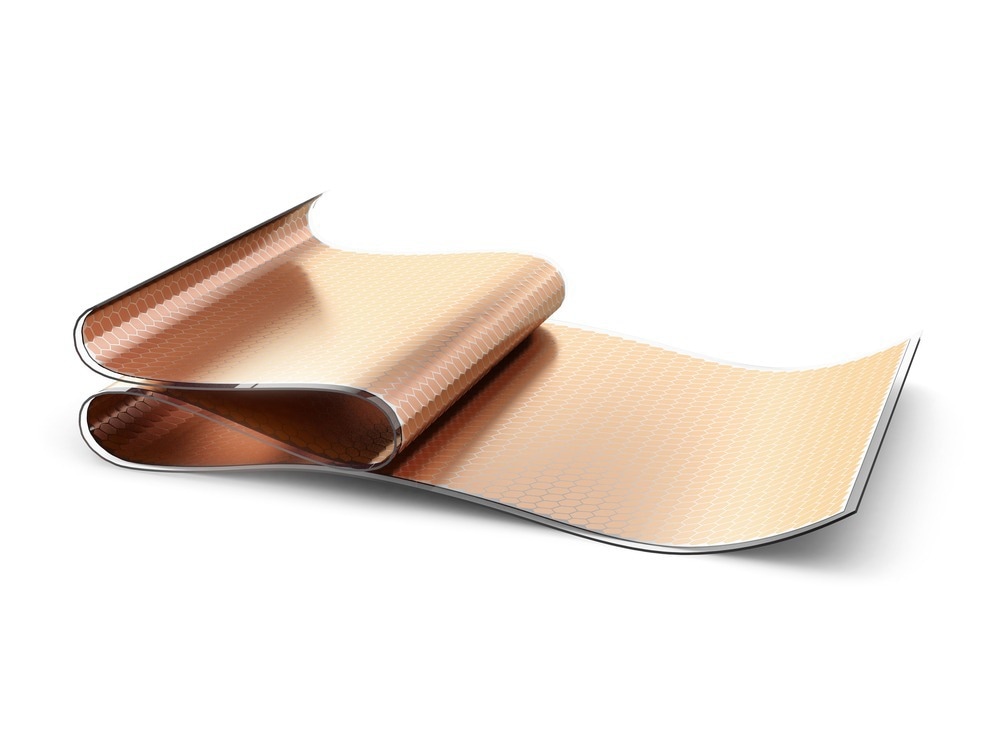

Graphene, a remarkable two-dimensional material composed of a single layer of carbon atoms arranged in a hexagonal lattice, has garnered substantial attention in the scientific community due to its extraordinary electrical, thermal, and mechanical properties. As researchers explore diverse applications for graphene, such as in electronics, energy storage, and sensors, one crucial aspect that has come under scrutiny is the effect of thermal processing on graphene thin films.

Image Credit: Iaremenko Sergii/Shutterstock.com

Graphene often starts as graphene oxide nanosheets containing oxygen-containing functional groups that limit its performance; thus, to unlock graphene's full potential, researchers have turned to heat treatment as a transformative technique. This article explores the profound effects of heat treatment on graphene thin films, focusing on the reduction of oxygen-containing functional groups and the enhancement of material properties, amongst other applications.

Reduction of Oxygen-Containing Functional Groups

Graphene oxide, a precursor to pristine graphene, possesses oxygen-containing functional groups such as hydroxyl (-OH), epoxy (-O-), and carboxyl (-COOH) groups. Such functional groups hinder the excellent electronic conductivity and mechanical strength of graphene. Heat treatment serves as a means to remove these functional groups and restore the pristine nature of graphene, resulting in several significant outcomes.

One such outcome via heat treatment in a reducing environment is the triggering of the removal of oxygen-containing functional groups from the graphene oxide nanosheets. This process is essential for transforming graphene oxide into reduced graphene oxide (rGO) or even pristine graphene.

Furthermore, the reduction of functional groups significantly enhances the electrical conductivity of the material. The resulting rGO exhibits electrical properties closer to those of pristine graphene, thus creating a more suitable material for various electronic applications.

The reduction process also assists in restoring the sp² carbon-carbon bonds, which are responsible for graphene's exceptional mechanical properties. As a result, heat-treated graphene films exhibit enhanced mechanical strength and durability.

Optimization of Material Properties

Heat treatment also plays a pivotal role in property optimization of graphene thin films. The effects of heat treatment on these films are manifold.

Researchers are able to manipulate the thickness of graphene platelets through heat treatment, and thus, by carefully controlling the reduction conditions, thinner films with a minimum thickness of approximately 0.37 nm are possible.

The removal of oxygen-containing groups during heat treatment, in addition, reduces the material's reactivity with environmental factors such as moisture and oxygen. The consequential effects include improved chemical stability and prolonged operational lifetimes for graphene-based devices.

Enhancing Structural Integrity

Graphene thin films often exhibit imperfections, wrinkles, and impurities that can hinder their performance. Heat treatment stands as a crucial technique for enhancing the structural integrity of these films.

Heat treatment at elevated temperatures promotes the migration of carbon atoms within the graphene lattice, effectively healing defects and dislocations. This results in improved electrical conductivity and mechanical strength, making the material more suitable for a range of applications.

Wrinkles and folds present on graphene films disrupt their uniformity and electrical properties. Implementing controlled heating helps to flatten these imperfections, ensuring a smoother and more robust film.

Tailoring Electrical Properties

Graphene's electronic properties are highly sensitive to its structure and the presence of defects, whereby the employment of heat treatment is able to precisely tailor these properties. An example of such is where heat treatment reduces the scattering of charge carriers in the graphene lattice, leading to an increase in carrier mobility. This is crucial for achieving high-performance electronic devices.

There has also been a growing interest in utilizing hot carriers in graphene for various technological applications, particularly in the optical and optoelectronic domains. Some of these applications include photodetection, nonlinear photonics, and luminescence.

Regarding photodetection, graphene can be used to detect light (photons) by harnessing the energy of hot carriers generated when photons are absorbed. In nonlinear photonics, hot carriers in graphene can facilitate nonlinear optical processes, which have applications in signal processing and high-speed data communication, and with luminescence, graphene is able to emit light (luminescence) through the recombining of hot carriers, offering possibilities in light-emitting devices.

Conclusion

In the pursuit of harnessing the extraordinary properties of graphene thin films for diverse applications, thermal processing has emerged as a pivotal technique for optimizing their structural, electronic, and chemical characteristics.

As research in this field continues to advance, it is probable that further innovations in thermal processing methodologies will unlock even greater possibilities for graphene-based technologies. Such advancements may pave the way for innovative solutions in electronics, energy storage, sensors, and various other fields, cementing graphene's status as an indispensable material in the 21st Century.

More from AZoM: The Exciting Future of Thin Film Electronics on Flexible Substrates

References and Further Reading

Akhavan O. The effect of heat treatment on formation of graphene thin films from graphene oxide nanosheets. Carbon. 2010 Feb;48(2):509–19.

Leow C, Kreider PB, Silvano Sommacal, Notthoff C, Kluth P, Compston P. Heat treated graphene thin films for reduced void content of interlaminar enhanced CF/PEEK composites. 2023 Jun 6;4(1).

Acik M, Chabal YJ. A Review on Reducing Graphene Oxide for Band Gap Engineering. Journal of Materials Science Research. 2012 Dec 6;2(1).

Lanzara A. Graphene Gets a Good Gap. Physics [Internet]. 2015 Sep 21;8. Available from: https://physics.aps.org/articles/v8/91

Lei S, Su N, Li M. Thermal-Resistance Effect of Graphene at High Temperatures in Nanoelectromechanical Temperature Sensors. Micromachines. 2022 Nov 26;13(12):2078–8.

Zhang Z, Zhao L, Shi J. Mechanics and Strategies for Wrinkling Suppression: A Review. Frontiers in Mechanical Engineering. 2022 May 25;8.

Massicotte M, Giancarlo Soavi, Principi A, Klaas-Jan Tielrooij. Hot carriers in graphene – fundamentals and applications. Nanoscale [Internet]. 2021 Jan 1 [cited 2023 Sep 22]; Available from: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC8118204/

Gao G, Liu D, Tang S, Huang C, He M, Guo Y, et al. Heat-Initiated Chemical Functionalization of Graphene. Scientific Reports. 2016 Jan 28;6(1).

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.