Sponsored by Metrohm AGReviewed by Olivia FrostOct 27 2023

Raman spectroscopy is a type of molecular spectroscopy that provides specific molecular data about materials.

Image Credit: Olha Kozachenko/shutterstock.com

This method is non-destructive and non-invasive and is widely utilized for rapid identification testing in material, chemical, biomedical (in medical diagnostics), and pharmaceutical research. Raman is also being increasingly employed by law enforcement.

However, a weakness of Raman spectroscopy is that samples may only be measured directly or through transparent containers.

This does not present a significant challenge in the laboratory, but for field-deployed handheld instrumentation, it is preferred for samples to be identified as they are, with the least possible sample handling and opening of packages.

Raman identification through opaque packaging would make the technology simpler for incoming raw materials in warehouses, as well as for customs agents, first responders, and others who require the rapid identification of materials without being in direct contact with them.

See-Through Raman Technology

See-through Raman Spectroscopy (STRamanTM) is a novel technology that increases the capability of Raman spectroscopy to measure samples located beneath diffusely scattering packaging material.

Typically, conventional Raman identification involves a very small sampling area and a high-power density at the laser focal point on the sample. This results in only a limited portion of a sample being measured and the possible heating or burning of samples.

The see-through technology has been developed to overcome these challenges, and it is available on a portable and handheld Raman system with 785 nm and 1064 nm laser excitation laser. This STRamanTM technology utilizes a much greater sampling area than the confocal method.

The design improves the relative intensity of the signal from the deeper layers, which provides a more effective sampling depth and enables materials to be measured inside visually opaque containers.

The greater sampling area has the added benefit of preventing sample damage by decreasing the power density and increasing measurement accuracy through the elimination of the heterogeneous effect.

Examples of See-Through Identification

The abilities of the 785 nm STRam for through-package identification has been demonstrated for packaging such as white polyethylene bottles, a common packaging for solid chemicals, and white and manila envelopes.1,2

Due to the increased sampling depth of the technology, a spectrum of material beneath opaque layers is collected. The package Raman signal contribution is removed, and the sample is correctly identified using advanced identification algorithms.

Employing the STRamanTM technology with 785 nm excitation enables identification through multiple opaque layers, colored plastic, and thick glass.

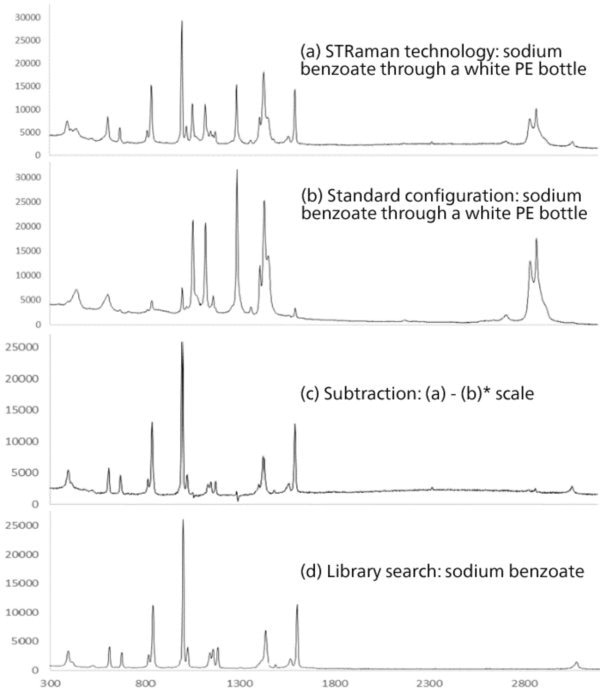

Figure 1 presents an example of the identification of sodium benzoate inside a white PE bottle. Coated tablets are also identifiable as the see-through technology infiltrates the coating layer and measures the Raman spectrum of the tablet underneath.

Figure 1. STRam identification of sodium benzoate through a white polyethylene bottle: (a) Spectrum measured through the bottle using the STRaman technology; (b) spectrum measured with a standard Raman configuration; (c) the result of scaled subtraction of (b) from (a); and (d) pure spectrum of sodium benzoate. Image Credit: B&W Tek

Due to the power density of the system being lower than conventional Raman’s highly focused signal, even colored tablet coatings and dark samples may be measured without the surface being burned by the laser.

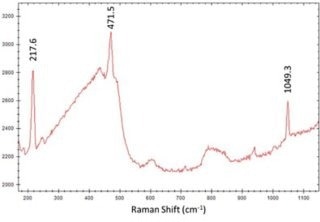

Figure 2 displays the Raman spectrum of a black powder collected using the STRam at full laser power without any burning occurring.

Figure 2. STRam spectrum of dark powder. Image Credit: B&W Tek

Many raw materials are supplied in kraft paper sacks of either single or multiple layers, occasionally with an additional plastic lining layer. When measured with 785 nm Raman, brown kraft paper and many other dark-colored materials exhibit a strong fluorescence.

Applying the STRaman technology to Metrohm’s 1064 nm Raman systems facilitates effective material identification through these challenging packaging materials.

To demonstrate this, many different multi-layer paper bags that were used as containers of raw material at pharmaceutical companies were obtained.

Several commonly used excipients with differing Raman scattering strengths were selected, and the STRamanTM at 1064 nm was employed to identify the samples through the paper bags.

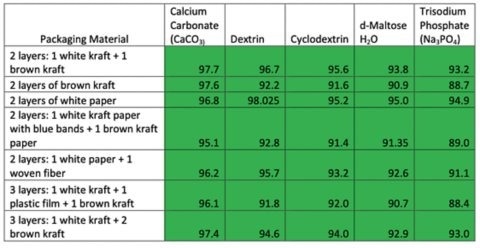

As displayed in Table 1, even the weakest Raman active material, trisodium phosphate (approximately 40 times weaker than calcium carbonate), is positively identified, i.e., the correct chemical is listed as the top hit, with a hit quality index (HGI) over a set threshold, and higher than the second hit by a set margin.

For this experiment, the HQI threshold was set to 85 while the margin was set to 2. However, at 785 nm excitation, trisodium phosphate is only positively identified through the white kraft paper bag.

Table 1. Positive identification of samples in kraft paper bags using STRam-1064 system. Source: B&W Tek

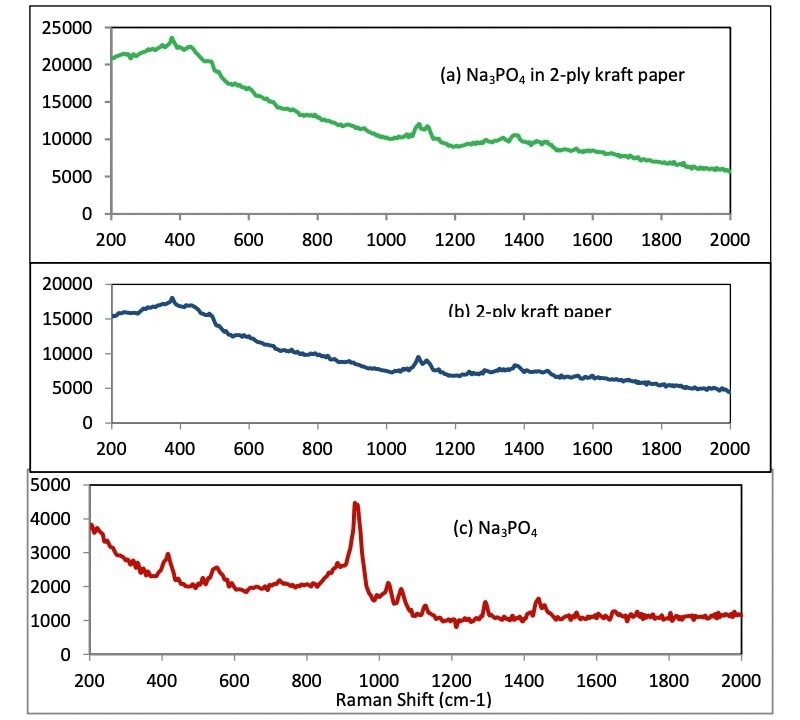

The spectrum of trisodium phosphate is presented in Figure 3, as measured through a two-ply bag of brown and white kraft paper, with a positive library search result.

Despite this spectrum being dominated by fluorescence and Raman features from the paper bag, the algorithm employed in STRaman can extract the signature of trisodium phosphate from this and reliably identify it.

Figure 3. STRam-1064 identification of trisodium phosphate in bilayer bag of white and brown kraft paper layers (a) Spectrum measured through the bilayer bag using the STRaman technology; (b) spectrum of the bilayer bag measured with standard Raman configuration; (c) pure spectrum of trisodium phosphate. Image Credit: B&W Tek

STRam Advantages

A further advantage of the STRam technology is its greater sampling area, which enables Raman to be more widely utilized and to deliver more repeatable results for heterogeneous samples, including natural products or mixed powders.

Conclusion

Raman presents the significant advantage of being able to measure samples inside packages, eliminating the requirement for sample preparation.

The improvements delivered by STRaman technology enable measuring to take place through opaque packages, such as fiber sacks, white plastic bottles, envelopes, kraft paper sacks, and even skin. This spectroscopic tool can be easily adopted in many working environments, in the lab, or the field.

The advancement of the technology for both 785 nm and 1064 nm laser excitation tackles even dark and highly colored packaging that are influenced by fluorescence. This makes Raman a viable technology for many new potential users.

References and Further Reading

- J. Zhao, K.A. Bakeev, J. Zhou, “Raman Spectroscopy Peers Through Packaging “, Photonics Spectra, February 2018, https://www.photonics.com/a62932/Raman_Spectroscopy_Peers_Through_Packaging

- K.A. Bakeev, “See-Through Science”, The Analytical Scientist, May 2018, https://www.metrohm.com/en_gb.html

This information has been sourced, reviewed and adapted from materials provided by B&W Tek.

For more information on this source, please visit B&W Tek.