Sponsored by Metrohm AGReviewed by Olivia FrostOct 30 2023

Palm oil comes from the fruit of oil palm trees (Elaeis guineensis) and is suitable for consumption. Oil palm trees only grow in tropical regions, being native to Africa and brought to southeast Asia just over 100 years ago.

Image Credit: SUWIT NGAOKAEW/shutterstock.com

At present, oil palm plantations in Malaysia and Indonesia supply more than 85% of palm oil used globally.1

High-quality crude red palm oil and palm kernel oil are processed and utilized in various products. Screening and quality control are crucial to guarantee that certain specifications are met for palm oil used in many industries. The use of near-infrared (NIR) spectroscopy is a straightforward method for this.

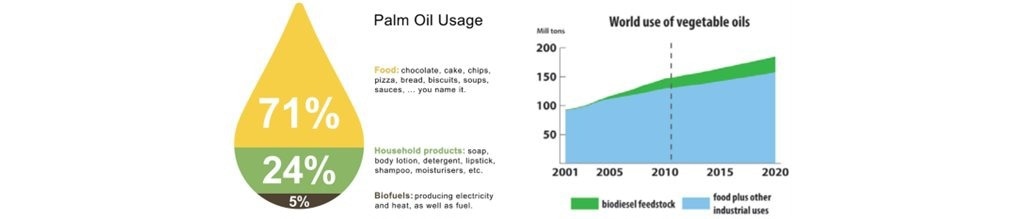

Palm Oil Use

Over 50% of prepackaged consumer goods contain palm oil. Examples of these products include instant noodles, pizza, and ice cream, as well as personal care and cosmetic products like shampoo, deodorant, lipstick, and toothpaste.2

Even cleaning products such as detergent and soap may contain palm oil. Additionally, this ubiquitous oil is found in animal feed and used as a biofuel in many parts of the globe, as shown in Figure 1.

Figure 1. Palm oil usage statistics 1. Image Credit: B&W Tek

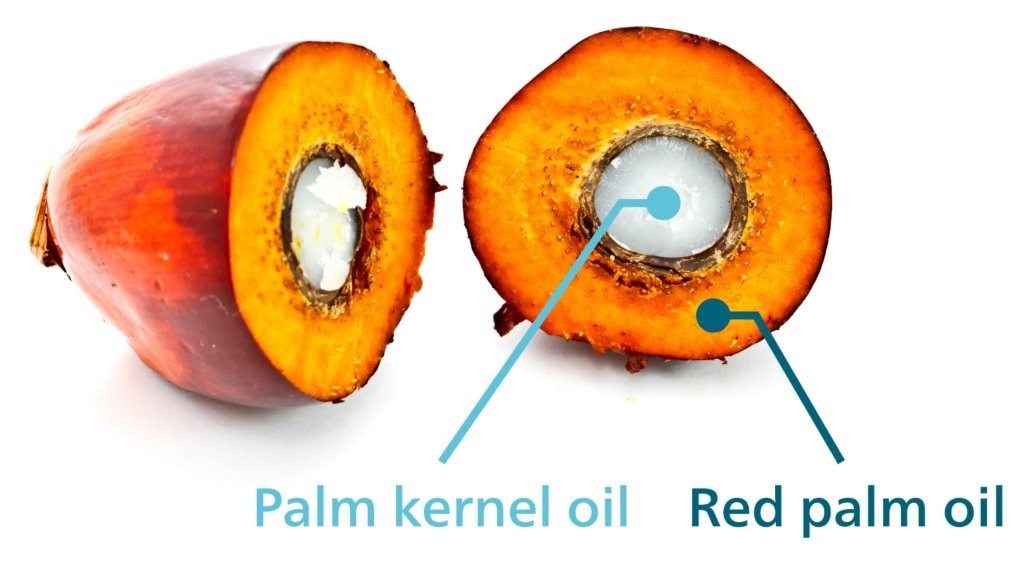

Two types of oil can be produced from oil palms, namely crude palm oil (or crude red palm oil) and crude palm kernel oil. Crude palm oil comes from pressing the flesh, while crude palm kernel oil comes from crushing the kernel (or the stone) in the center of the fruit, as displayed in Figure 2.

Figure 2. Cross-section of fruit from an oil palm tree showing the origin of palm kernel oil and red palm oil. Image Credit: B&W Tek

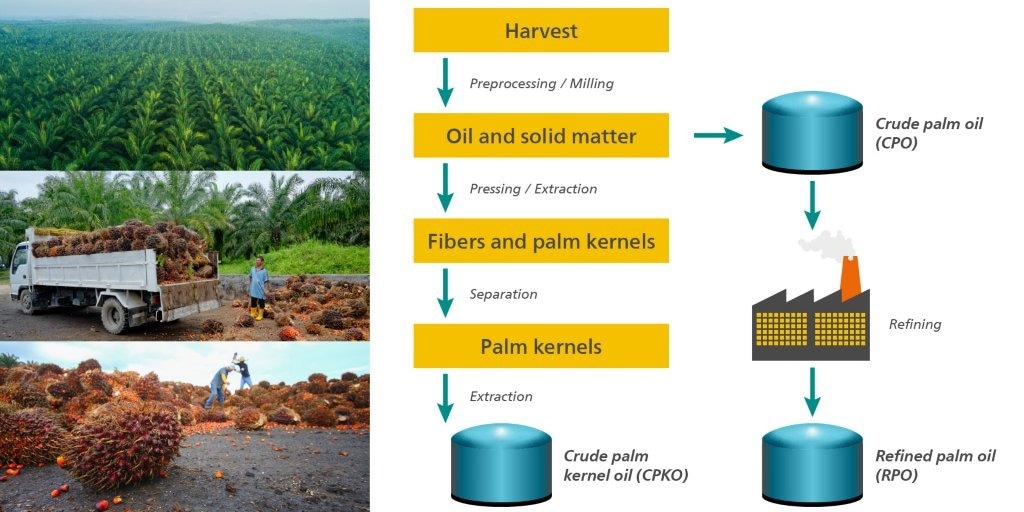

Processing Palm Oil: Milling and Refining

The milling and refining process of palm oil is presented in Figure 3. After the fruit has been milled, the resultant crude palm oil (CPO) is naturally red due to its high beta-carotene content.

Crude red palm oil that has undergone refining, bleaching, and deodorizing (i.e., RBD palm oil) is light yellow or even colorless because it no longer contains carotenoids.

Figure 3. Illustration of the milling and refining process of palm oil. Image Credit: B&W Tek

After the milling process is complete, the crude palm oil undergoes fractionation. This involves both crystallization and separation processes where liquid (olein) and solid (palm stearin) fractions of CPO are acquired. Melting and degumming processes are employed to remove any impurities from these fractions.

The oil is then refined further, being filtered and bleached to remove coloration and scents. This results in RBD palm oil and free fatty acids. RBD palm oil can be fractionated further to either produce cooking oil or to use as an ingredient in other products.

Quality Control of Palm Oil

During the production of palm oil, there are many stages where monitoring can take place for quality control (QC) purposes. Near-infrared spectroscopy is a technique that can be applied for QC during palm oil production, as well as by companies that procure palm oil and must evaluate its quality before it is used in other products.

How NIR Spectroscopy Works

Light and matter interact in many ways. However, the light used in spectroscopic techniques (such as NIRS) is often described by the wavelength or wavenumbers instead of the applied energy.

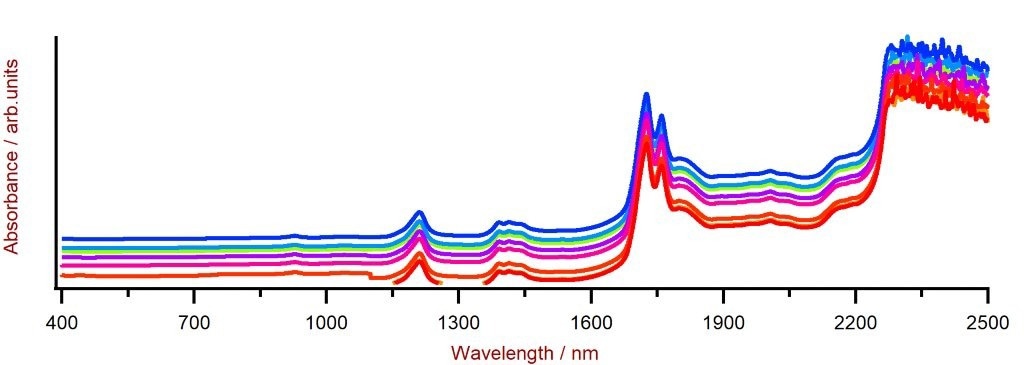

A NIR spectrometer (such as the Metrohm DS2500 Liquid Analyzer) measures this interaction to produce spectra from a sample, as shown in Figure 4.

Figure 4. Palm oil spectra resulting from the interaction of NIR light with the respective samples. Image Credit: B&W Tek

This analytical method is relatively sensitive to specific functional groups in samples, including -OH, -NH, CH, and -SH.

This makes NIRS ideal for the quantification of chemical parameters in palm oil like free fatty acids (FFA), water (moisture) content, deterioration of bleachability index (DOBI), and iodine value (IV).

The light-matter interaction depends upon the sample. This enables rheological and physical parameters (e.g., viscosity and density) to be measured. This abundance of data is contained in just one NIR spectrum, making this method well-suited for quick multiparameter analysis.

Measuring Mode

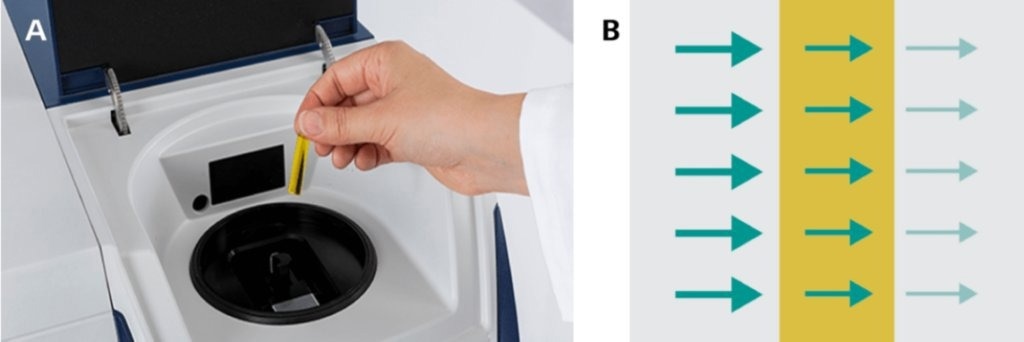

The type of sample being considered affects which NIRS measuring mode is to be used. The transmission mode is most suited to the analysis of liquid samples like palm oil, as shown in Figure 5. In this case, NIR light is absorbed while traveling through the sample, and any unabsorbed NIR light is detected.

Figure 5. A. Measurements of liquids are typically done with disposable vials. B. The NIRS measurement mode is known as transmission, where light travels through the sample while being absorbed (from left to right in the illustration). Image Credit: B&W Tek

Advantages of Utilizing NIR Spectroscopy

The simplicity of sample measurement and speed are significant advantages of using NIR spectroscopy for QC. Advantages include:

- Fast method, with results obtained in less than one minute.

- No sample preparation is required, and the sample can be measured as-is.

- Low cost per sample, with no reagents required for analysis.

- Environmentally friendly, producing no waste.

- Non-destructive measurement, enabling samples to be reused after analysis.

- Easy operation, allowing even inexperienced users to be successful right away.

To learn more about NIRS as a secondary method, you can visit Metrohm’s various blog posts on the topic.

ASTM Compliance of NIRS for Quality Control

ASTM E1655: Standard Practices for Infrared Multivariate Quantitative Analysis

These standard practices cover a guide for the multivariate calibration of infrared spectrometers employed to determine a material’s chemical or physical characteristics.

These practices apply to analyses carried out in the near-infrared (NIR) spectral region (approximately 780 to 2500 nm) through the mid-infrared (MIR) spectral region (approximately 4000 to 400 cm-1).

Typical Applications and Parameters for NIRS Analysis

Palm oil products must undergo numerous standardized test methods to determine their physical and chemical properties. Lab testing is a crucial part of research and development, as well as QC.

Table 1 details the most relevant test parameters for the quality control of various forms of palm oil, including crude palm kernel oil (CPKO), crude palm oil (CPO), and refined, bleached, and deodorized (RBD) palm oil.

Table 1. Many QC parameters for palm oil products are measured by conventional laboratory techniques which require chemical reagents, skilled technicians, and sample preparation. NIRS is a suitable alternative technique that can determine all these parameters in less than a minute. Source: B&W Tek

| Parameter |

Conventional (primary) method |

| Moisture |

Karl Fischer titration |

| Free Fatty Acids (FFA) |

Titration |

| Iodine Value (IV) |

Titration |

| Deterioration of Bleachability Index (DOBI) |

Photometry |

| Carotene |

Photometry |

NIRS: A Turnkey Solution for Palm Oil Analysis

Metrohm provides NIRS as a turnkey solution for palm oil analysis with pre-calibration models that are ready to use for the determination of the moisture (water %) iodine value (IV), and free fatty acids (FFA) content, as listed in Table 2.

Different, specific pre-calibrations are dedicated to analyzing products such as crude palm oil (CPO), crude palm kernel oil (CPKO), or refined, bleached, and deodorized (RBD) crude palm stearin or olein. These pre-calibration models enable this turnkey solution to be employed immediately, without any method development.

Table 2. Available Metrohm NIRS pre-calibration models for selected palm oil products shown with measuring range and standard error of cross-validation (SECV). Source: B&W Tek

| Parameter |

|

CPKO |

CPO |

RBD |

| FFA (%) |

Range |

0–4 |

2.5–6 |

0–0.25 |

| SECV |

0.11 |

0.26 |

0.03 |

| Moisture (%) |

Range |

0–0.3 |

0–0.3 |

0–0.1 |

| SECV |

0.03 |

0.05 |

0.01 |

| IV |

Range |

7–19 |

49–53 |

21–63 |

| SECV |

0.27 |

0.22 |

0.56 |

Table 3 presents the results of the crude palm oil analysis carried out with the Metrohm DS2500 Liquid Analyzer. All constituents measured using NIRS display robust correlation values, while the standard error of cross-validation (SECV) is close in value to the standard error of calibration (SEC) for all models.

Table 3. Example of multi-component analysis in crude palm oil (CPO) by NIRS. Source: B&W Tek

| Figures of merit |

FFA |

IV |

Moisture content |

DOBI |

Carotene content |

| R2 |

0.835 |

0.911 |

0.638 |

0.842 |

0.677 |

| SEC |

0.266% |

184 mg/100 g |

0.046% |

0.17 |

22.9 µg/g (ppm) |

| SECV |

0.270% |

210 mg/100 g |

0.047% |

0.19 |

23.4 µg/g (ppm) |

Conclusion

Near-infrared spectroscopy is well-suited to the analysis of the main quality parameters in CPO, CPKO, and RBD palm oil.

Only one NIRS instrument is needed to measure multiple QC parameters in significantly less time than alternative analytical techniques. Up to 30 minutes is required to analyze palm oil samples with primary methods such as photometry, titration, and Karl Fischer titration.

Conventional wet chemistry determination demands sample preparation, chemical reagents, multiple instruments, and skilled laboratory personnel.

However, using NIRS for the multiparameter analysis of palm oil requires less than one minute. Higher sample throughput is possible due to the fast time to result and because sample preparation is not needed. This also lowers the cost per sample due to time savings and the lack of chemicals required.

References and Further Reading

- WikiCorporates. Palm Oil Industry. https://www.wikicorporates.org/wiki/Palm_Oil_Industry (accessed 2023-09-07).

- World Wildlife Fund. Which Everyday Products Contain Palm Oil?. Palm Oil. https://www.worldwildlife.org/pages/which-everyday-products-contain-palm-oil (accessed 2023-09-07).

Acknowledgments

Produced from materials originally authored by Wim Guns and Dr. Alyson Lanciki at Metrohm International Headquarters, Switzerland.

This information has been sourced, reviewed and adapted from materials provided by B&W Tek.

For more information on this source, please visit B&W Tek.