Polyvinylchloride (PVC), a versatile, durable, and highly recyclable material, finds extensive use in various sectors like building and construction (e.g., window frames, water pipes, flooring), automotive (interior components and seat coverings), and multiple other industries.

Image Credit: shutterstock.com/Athapet Piruksa

In the past, PVC included lead (Pb) as a stabilizer, but due to the health and environmental hazards associated with Pb, it has gradually been phased out of numerous products. Concurrently, certain governments have set ambitious targets to promote a circular economy and encourage manufacturers to employ reclaimed materials.

The recycling process might potentially reintroduce Pb-containing PVC to the market if not vigilantly controlled. Presently, PVC products placed on the market must contain less than 0.1 wt% Pb. Nevertheless, temporary exceptions are occasionally made for recycled rigid PVC, allowing a maximum Pb content of 1.5 wt%.

Image Credit: Hitachi High-Tech Analytical Science

To ensure compliance, manufacturers must inspect the Pb content in incoming reclaimed PVC. This enables them to determine whether it should be rejected, blended with new primary PVC to reduce the Pb content, or used as is.

The ideal method for this analysis is energy-dispersive X-Ray fluorescence (EDXRF), as it is non-destructive, swift, cost-efficient, and user-friendly. This allows operators to assess incoming materials and final products, ensuring they meet the required specifications.

Image Credit: Hitachi High-Tech Analytical Science

Instrumentation

With the Hitachi High-Tech X-MET8000 handheld XRF analyzer, assessing recycled PVC is easy. The X-MET comes pre-calibrated from the factory, ready for immediate use. Routine analysis involves placing the ground PVC into a sample cup (see Sample Preparation). To enhance operator safety, the prepared sample cups can be measured using the light stand, safety shield, or benchtop stand.

Results are available within seconds, eliminating the need for waiting for time-consuming and costly laboratory analyses. This allows users to make prompt decisions on the spot.

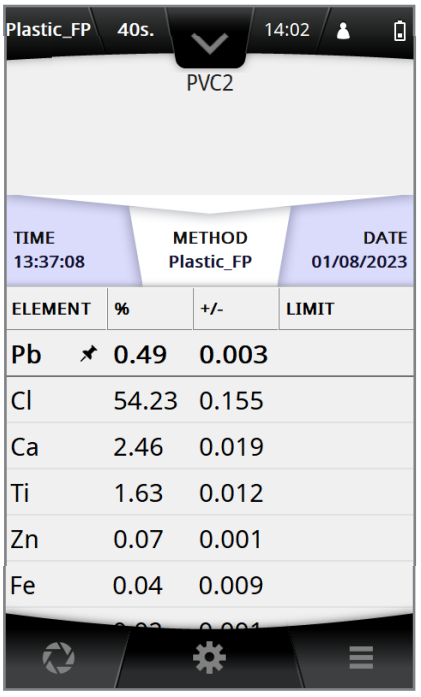

Pass/Fail notifications can be set up for quick acceptance or rejection of incoming products, assuring that the final product complies with the Pb content requirements. The results can also be customized to prioritize specific elements (see example below, with Pb at the top of the list).

The X-MET8000 combines a high-performance X-Ray tube and Hitachi High-Tech’s large-area silicon drift detector (SDD) to deliver the speed and efficiency necessary for rapid material verification.

Its environmental sealing (IP54 rating) and industrial design ensure minimal dust and water ingress, even in challenging environments.

With storage capacity for up to 100,000 results on the analyzer, operators can conveniently access both recent and previous results. These can be printed using the optional Bluetooth printer, downloaded to a USB memory device, or utilized to generate customized reports.

Results can be uploaded to the ExTOPE Connect cloud service for real-time access to the data from anywhere, at any time.

Sample Preparation

Recycled PVC is assessed in a ground state. The process for preparing samples is straightforward: The powdered PVC is placed into a sample cup, covered with a film layer, and the cup ring is slid down to secure the film. The cup is then inverted and lightly tapped on a clean, dry surface to compact the powder within.

When employing the light stand, the prepared cup is balanced on the X-MET nose, and the safety shield is attached to the analyzer. The X-MET trigger is pushed to initiate the analysis. If the benchtop stand is used, the cup is positioned in the stand, the lid is closed, and the trigger is pressed to begin the analysis.

Preparing the sample cup. Image Credit: Hitachi High-Tech Analytical Science

Analysis setup with the light stand. Image Credit: Hitachi High-Tech Analytical Science

Analysis setup with the benchtop stand. Image Credit: Hitachi High-Tech Analytical Science

Performance and Results

In this application, the Plastic FP calibration was selected to measure various recycled PVC powders, with a 40-second measurement time. This factory calibration is optimized for quickly determining 27 elements in plastic matrices.

In addition to lead (Pb), the calibration covers Cl, K, Ca, Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, As, Se, Br, Sr, Zr, Ag, Cd, Sn, Sb, Ba, Ta, Au, Hg and Bi. Initial results appear on the X-MET screen in seconds and continue updating throughout the full analysis.

To assess the impact of sample preparation (reproducibility), two samples underwent five measurements each, with the sample cups shaken between each measurement. The results are presented in Table 1.

Analysis repeatability was demonstrated by conducting five measurements on the same two samples in a static position. The results are shown in Table 2.

Table 1. Reproducibility data (samples shaken between analyses). Source: Hitachi High-Tech Analytical Science

| Measurement # |

Sample 1 Pb, wt% |

Sample 2 Pb, wt% |

| 1 |

1.61 |

0.55 |

| 2 |

1.44 |

0.52 |

| 3 |

1.81 |

0.50 |

| 4 |

1.64 |

0.62 |

| 5 |

1.57 |

0.49 |

| Average |

1.61 |

0.54 |

| Standard deviation |

0.13 |

0.05 |

Table 2. Repeatability data (samples in static position). Source: Hitachi High-Tech Analytical Science

| Measurement # |

Sample 1 Pb, wt% |

Sample 2 Pb, wt% |

| 1 |

1.57 |

0.58 |

| 2 |

1.65 |

0.52 |

| 3 |

1.65 |

0.55 |

| 4 |

1.48 |

0.55 |

| 5 |

1.54 |

0.53 |

| Average |

1.58 |

0.55 |

| Standard deviation |

0.07 |

0.02 |

The data indicates excellent instrument precision. The most significant variation in measurements arises from the sample’s form. If enhanced reproducibility is necessary, samples should be ground into a finer powder to ensure greater homogeneity.

The limit of quantification (LOQ) is the lowest content that can be confidently measured in a given matrix. The X-MET’s LOQ for Pb in PVC powder is 100 ppm (0.01 wt%) with a 40-second measurement time. This means that if the Pb content limit needs to be reduced in the future, the X-MET will remain the ideal tool for the task.

The X-MET’s results screen. Image Credit: Hitachi High-Tech Analytical Science

Summary

By following uncomplicated sample preparation steps, PVC manufacturers can employ the X-MET8000 on-site to assess the Pb content of reclaimed PVC material. With results available within seconds, decisions can be made promptly regarding whether the material can be used as is or needs further blending.

This offers significant time and cost savings compared to traditional laboratory tests while ensuring consistent final product quality.

This information has been sourced, reviewed and adapted from materials provided by Hitachi High-Tech Analytical Science.

For more information on this source, please visit Hitachi High-Tech Analytical Science.