This article discusses the frequently asked questions about six varieties of calibrated Gardco Viscosity Cups created by The Paul N. Gardner Company.

Image Credit: Paul N. Gardner Company, Inc.

All makers of liquid or semi-liquid materials are concerned about the 'flow property' of their goods. This property, an inner resistance to flow, is called viscosity.

Typically, the viscosity of a product is controlled by the amount of dilution. Thus, measuring viscosity is essential to ensure consistent and needed performance and manage product expenses.

Viscosity's base unit is the Poise, representing the force necessary to move one surface of the known area at a certain speed concerning another surface separated by a viscous material.

The Centipoise is a Poise divided by 100. The Stoke is a Poise divided by the product's density (or weight per gallon in pounds multiplied by 0.1202) used when gravity affects product flow.

Once the Stoke value is known, the equivalent Poise value is determined by multiplying the Stoke value by the product's density (or weight per gallon in pounds multiplied by 0.1202). The Centistoke is a Stoke divided by 100.

Instruments for measuring viscosity are generally categorized into two types:

- Rotational Viscometers, which measure in Poises

- Viscosity Cups, which measure in Stokes

While many other specialized viscosity measuring instruments exist, they go beyond this discussion's scope. Most rotational instruments function at multiple speeds, allowing assessment of a product at various shear rates. Thus, they are suitable for higher-level product evaluation compared to viscosity cups.

They are also used for assessing materials with a high solid-material ratio and those beyond the range of instruments reliant on gravity for flow. They tend to be costly, with prices varying based on sophistication, range, temperature control, and data display.

Measuring viscosity through viscosity cups has become the preferred method for production control due to their user-friendly nature, durability, improved accuracy, and relatively low cost.

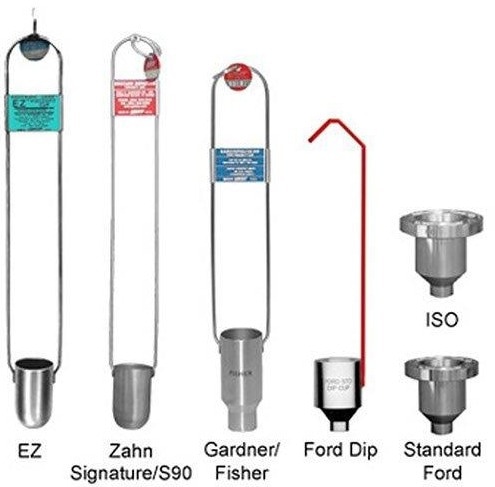

Viscosity cups fall into two types, both standardized and calibrated by the Paul N. Gardner Company, as detailed below:

- Dip Viscosity Cups

- EZ (Equivalent Zahn) Viscosity Cups - 5 Cup Ranges

- Zahn Signature Cups - 5 Cup Ranges

- Ford Dip Viscosity Cups - 6 Cup Ranges

- Gardco/Fisher Dip Viscosity Cups - 4 Cup Ranges

- Laboratory or “Ring Stand” Viscosity Cups

- Ford Standard Viscosity Cups - 6 Cup Ranges

- Gardco/ISO Viscosity Cups - 3 Cup Ranges

Choosing and using viscosity cups has led to confusion because of the numerous available types and insufficient standardization among manufacturers. The remainder of this text aims to address the most frequently asked questions about viscosity cups and provide their answers.

The questions are grouped into the following categories:

- Cup Selection

- Cup Accuracy

- Cup Standardization and Certification

- Cup Use

- Temperature Control

A. Cup Selection

- Q. My company tasked me with establishing a production control procedure for viscosity measurement, as none currently exists. We are a small, single-plant company with limited funds. Although suppliers or customers do not presently require viscosity measurements, this might change. Using a viscosity cup is likely the easiest and most cost-effective way to initiate such a program. Which viscosity cup should I purchase?

A. We recommend the new EZ (Equivalent Zahn) Viscosity Cup. Priced similarly to the Zahn Signature cup, it holds the advantage of complying with ASTM specifications, widely accepted by most users. Opting for the EZ Cup positions you better for potential collaborations in the future.

- Q. What distinguishes the EZ Cup from the Zahn Signature Cup?

A. Both cups share a close resemblance and serve similar purposes. The EZ Cups feature design enhancements not present in Zahn Signature Cups, with key advantages in ASTM specification compliance and production procedures allowing closer adherence to performance specifications. EZ cups maintain a tolerance within 3%, while Zahn Signature cups tolerate within 5%.

- Q. Colleagues in similar situations mention using Zahn Signature Cups and express satisfaction with their results. If I opt for this cup, despite not meeting ASTM specifications, can I be certain it will remain available?

A. Yes. The Paul N. Gardner Company is committed to keeping this cup available as long as there is demand. Conversion tables are accessible for translating results between Zahn Signature and EZ cups.

Production procedures are undergoing revision to enhance Zahn Signature cup uniformity.

Cups produced under this new process, termed Zahn Signature Series 90 cups, will comply with the flow characteristics of all prior Zahn Signature cups sold. However, they do not conform to the ASTM method specifying drain time characteristics.

- Q. Why was the Ford Dip Cup not recommended?

A. Given your earlier inquiry, it was assumed that you were seeking the most economical option. We suggest considering this cup if your budget allows for a roughly 75% higher equipment investment. It has the added benefit of an easily removable orifice, featuring a flow path length greater than its diameter.

This enhances sensitivity and accuracy. Additionally, the results obtained with the Standard Ford Cup are halved, offering a significant advantage. This could be beneficial if you plan to establish a formal laboratory later on and wish to utilize the widely popular Standard Ford cup.

The Ford Cup maintains a tolerance within 2%, and these cups are precision-machined from solid aluminum bar stock. The Ford Dip Cups offer six readily interchangeable orifices from size no. 0 to no. 5. You can opt to purchase a single cup and the desired orifices, resulting in substantial cost savings.

- Q. What about the Gardco/Fisher Cup?

A. It is a commendable cup, also machined from solid aluminum bar stock and featuring a removable orifice of considerable length. It provides a notable accuracy advantage with a larger volume than other dip cups. However, it is the most expensive, costing about 2.5 times more than the EZ cup.

Unless you anticipate doing business with General Motors or its suppliers, there is little reason to standardize on this cup.

It is not as widely used as the Zahn Signature, EZ, or Ford Dip Cup. Gardco/Fisher Cups come with four easily removable, interchangeable orifices from size no. 1 to no. 4. You can purchase one cup and the desired orifices, leading to substantial cost savings.

- Q. The ISO (International Standards Organization) Viscosity Cup has not been mentioned. Is there any advantage in considering this cup?

A. Not unless you are contemplating future international business. It resembles the Standard Ford Cup in appearance and use but has different flow characteristics. Like the Standard Ford Cup, this cup features removable, interchangeable orifices.

- Q. Which cup numbers (ranges) should I buy?

A. It depends on the viscosity range you need to consider. Notably, over half of the EZ and Zahn Signature Cups sold are #2. The lightest materials require #1 and the heaviest call for #5.

- Q. How long does it take to perform a viscosity measurement with the EZ Viscosity Cup?

A. The suggested minimum time is 1.5 times the duration for water to drain from the cup or 10 seconds, whichever is longer. Below the 1.5 threshold, the measure primarily captures turbulence at the orifice rather than viscosity. Below 10 seconds, errors in measuring drain time become too significant.

The maximum recommended drain time is 60 seconds. The cup's exterior becomes coated with the test material, leading to potential evaporation and subsequent cooling of the contents or hardening on the surface, which could introduce errors.

The minimum timeframe applies to all viscosity cups, whether of the dip or laboratory ring stand type. The maximum applies solely to dip cups, as the laboratory types—Standard Ford or ISO cups—do not get coated on the exterior.

- Q. It seems like the EZ or Zahn Cup would suit my needs. What exactly is an EZ or Zahn Cup?

A. These cups are crafted from stainless steel and have a bullet-shaped design (cylindrical with a hemispherical bottom) with a specified size orifice drilled at the exact center of the spherical base.

Attached to the cup is a stainless steel wire loop extending 12 inches above the cup and ending in a one-inch ring. During use, the cup is held by the ring and dipped into the material for measurement. As the cup is lifted, a timing device is started.

Observing the cup's drainage, the timing device is stopped upon the first break in the efflux stream, about two inches below the cup's base. Results are reported in efflux seconds.

- Q. Are there multiple producers of the EZ Viscosity Cup?

A. No, the Paul N. Gardner Company exclusively manufactures the EZ Viscosity Cup. Production procedures and cup calibration ensure that drain times with a specified viscous material, traceable to the National Institute of Standards and Technology, are within 3% of the target.

- Q. Are there multiple producers of the Zahn Viscosity Cup?

A. Yes, the Zahn Cup is produced not only by various suppliers in the United States but also in countries worldwide, including England, France, Italy, and Germany. However, the Paul N. Gardner Company is the sole licensed producer authorized by the inventor E. A. Zahn.

- Q. Do Zahn Cups of the same orifice size from different producers yield identical readings for the same liquid?

A. No, differences exceeding 50% have been observed.

- Q. How long have Zahn Viscosity Cups been in use?

A. Zahn Viscosity Cups have gained rapid popularity since the latter half of the 1940s.

B. Cup Accuracy

Supposing I proceed with the EZ Cup for my viscosity measurement plan, I would like to delve into inquiries concerning cup accuracy, standardization, usage, and ideal conditions for conducting viscosity measurements.

- Q. What is meant by cup accuracy?

A. This question essentially comprises two crucial aspects: the agreement between cups of the same number and producer, both within a set and when purchased at different times. The second aspect pertains to the cups consistently delivering long-term results that preferably align in some quantifiable manner with fundamental viscosity units.

- Q. It seems that the latter part of cup accuracy is more critical—similar to assuming a 12-inch ruler's length remains constant across all rulers. How does this apply to viscosity cups?

A. This aspect holds immense significance and applies specifically to cups manufactured by the Paul N. Gardner Company. An investigation, funded in the early 1980s, addressed this issue.

One key finding highlighted the need to relate the cups to a standard surpassing a mere dimensional drawing or a producer's "standard" cup on a shelf. The solution lay in standard viscous materials.

These materials, measured in Centistoke Viscosity units with an accuracy within 0.25% of the labeled value, are traceable to the U.S. National Institute of Standards and Technology. They serve in calibrating all viscosity cups produced by and available from The Paul N. Gardner Company.

- Q. What level of accuracy can I reasonably anticipate from any viscosity cup purchased from The Paul N. Gardner Company?

A. Each cup type and number produced by The Paul N. Gardner Company undergoes calibration using a set of standard oils that cover each cup's useful range. This data derives a precise mathematical formula, correlating efflux time in seconds to centistoke viscosity.

This formula converts centistoke values for a specific material into drain times in seconds for a given cup. Through the use of appropriate calibration oils in the midpoint range during cup calibration, along with meticulous control of mechanical variables, we maintain cups within the following tolerances:

- Zahn Signature Cups 5%

- EZ Viscosity Cups 3%

- Ford Dip Viscosity Cups 2%

- Gardco/Fisher Dip Viscosity Cups 2%

- Ford Standard Cups 2%

- Gardco/ISO Viscosity Cups 2%

This rigorous procedure ensures that each cup within a production lot falls within these tolerance limits but also prevents long-term drift from the established standard by periodically renewing the standard calibration oils.

- Q. What factors should I look for in cups produced by others that might affect cup accuracy or consistency between cups?

A. This response pertains solely to Zahn-type cups:

- Height-to-diameter ratio and cup volume: Variations of up to 12% have been observed in cup volume.

- Lack of welding between the cup and support wire loop: This prevents symmetry between the cup axis and the support loop, causing the efflux stream to deviate from the orifice center and resulting in significant errors.

- Orifice diameter: While most producers accurately replicate the published diameter, this remains a major issue. Orifice diameter adjustment can compensate for other cup variables. The Paul N. Gardner Company adjusts orifice diameter to align with specified performance criteria.

- Off-centered orifice placement: When the orifice is not at the exact center of the cup bottom, the efflux stream bends, leading to considerable errors.

- Non-round orifice or uneven tooling marks: Both conditions detract from cup accuracy.

- Variations in cup sidewall thickness: Variations of up to 50% have been observed. Since orifice length depends on sidewall thickness and orifice length directly affects flow time, sidewall thickness variation is a serious concern.

- Q. How does orifice length impact drain time?

A. Generally, the longer the orifice length, the longer the drain time. Drain time tends to be roughly directly proportional to orifice length.

- Q. How does orifice diameter affect drain time?

A. A larger orifice diameter results in shorter drain times. Orifice diameter significantly influences drain time, roughly being inversely proportional to the fourth power of the orifice radius.

- Q. If I opt for the EZ Cup, can I convert its readings to those of other cups produced by the Paul N. Gardner Company?

A. Yes, all Gardco cups are calibrated using a mathematical formula that aligns with the fundamental unit of viscosity, centistokes. Consequently, any drain time in seconds from a specific cup can be converted not only to centistokes but also to any other Gardco cup within the cup's range.

A comprehensive wall-size chart measuring 24" x 36" displays this conversion for the 29 cups across the six types produced by The Paul N. Gardner Company. The conversion, in 5% increments from 7.5 to 1387 centistokes, remains highly accurate as long as the material under consideration does not significantly deviate from a true liquid.

The chart contains crucial information such as cup range, formula constants, calibration standard oil, cup sensitivity, and standard cup use.

C. Cup Standardization and Certification

- Q. Does the Zahn Signature cup meet the requirements of ASTM Method D-4212?

A. No, the Zahn Signature Cups, as initially licensed to the Paul N. Gardner Company, fall short of meeting the drain time portion of ASTM Method D-4212.

However, to accommodate the numerous Zahn Signature Cup owners who have established their records with these cups, they have been standardized using mathematical formulas correlating drain time to centistokes.

This allows the conversion of results to cups that comply with ASTM Method D-4212. Conversion tables between the Zahn Signature and EZ cups are also available for results.

- Q. Do the EZ cups meet the requirements of ASTM Method D-4212?

A. Yes, the EZ cups are specifically designed to meet all requirements of ASTM Method D-4212. This design ensures retention of the standard set for the Zahn Signature Series while providing a similar series of cups with improved design and compliance with D-4212. EZ cups have a tolerance of 3%.

- Q. An acquaintance is bidding on a project requiring viscosity measuring equipment compliance with MIL-STD 45662A. What does this reference mean?

A. MIL-STD 45662A is a document outlining specific procedures for the certification of various types of testing equipment to an industry standard. Certification procedures for viscosity cups fall under this document.

It includes requirements for periodic evaluation of master thermometers and timing devices by the U.S. National Institute for Standards and Technology.

The document also specifies environmental conditions for certification procedures and mandates using standard viscous materials traceable to the U.S. National Institute for Standards and Technology.

- Q. Is there a chance I might need to comply with MIL-STD 45662A?

A. If you engage in a contract with any government agency, particularly at the federal level, including the military, a probable requirement is that your measuring equipment must be certified following this document.

- Q. Do your viscosity cups meet the criteria for certification under MIL-STD 45662A?

A. Yes, any viscosity cup from the Paul N. Gardner Company qualifies for certification under MIL-STD 45662A, and this certification is available as an additional service.

- Q. What does this certification entail, and what would I receive?

A. You would obtain a certificate identifying you as the owner of a specific viscosity cup, clearly identified. The certificate would list the qualifications for and conditions of certification.

It would also include actual results from running standard oils in your cup, featuring the target drain time for the oil used and the average from multiple drain time runs with your cup.

Any difference between the target drain time and your cup is provided as a correction factor. The certificate is dated and signed by the technician conducting the work and by their supervisor.

D. Cup Use

- Q. Please outline the correct procedure for using a dip-type viscosity cup.

A.

- Ensure the product to be measured is at the specified temperature, well-mixed, and free of air bubbles. Have the appropriate cup for the viscosity range on hand.

- Inspect the cup, ensuring it is clean, with particular attention to the orifice area.

- Hold the ring at the top and immerse the cup in the material so the top edge is about half an inch below the liquid level.

- Quickly withdraw the cup, starting a timing device simultaneously.

- Observe the efflux stream, stopping the timing device at the first distinct break, one to two inches below the cup's bottom.

- Record seconds of drain time, the temperature at measurement, and cup type and number.

- If desired, use the Gardco Viscosity Conversion Chart accompanying each cup to convert seconds of efflux time to centistokes viscosity.

- Q. Why should I hold the cup by the ring rather than the wire loop?

A. Holding the cup by the ring ensures its vertical position during the drain period. If not held vertically, the efflux stream may drift, causing errors. (Note: This does not apply to the Ford Dip Cup where the orifice extends below the immediate surrounding cup surface.)

- Q. What type of thermometer should I use to measure the temperature of the test material?

A. Use any thermometer with rapid response, readable to the nearest tenth of a degree Celsius or two-tenths of a degree Fahrenheit. Bi-metallic thermometers readable to the nearest 1/2 degree Celsius (1 °F) may suffice for less critical applications.

- Q. What type of timer should I use to measure drain time?

A. Any timer registering to the nearest tenth of a second is suitable. The electronic digital type, measuring to the nearest 1/100 second, is becoming more popular.

- Q. Should I convert drain time seconds to centistokes when recording results?

A. It depends on your data's end use. If for internal comparisons, conversion may not be necessary. Conversion is likely advisable for other purposes, and it can always be done later.

- Q. Is it best to take averages of several readings?

A. Averaging multiple readings reduces operator error. In calibration and certification work, at least three determinations are typically averaged.

- Q. What care should be taken of the cup after use?

A. Thoroughly clean the cup unless repeating readings with the same material immediately. Regardless, avoid exposing the cup to air after use; instead, return it to the test material. Drying of materials on the cup surfaces can lead to errors in subsequent determinations or make the cup more challenging to clean.

E. Temperature Control

- Q. I have been hearing more and more about the importance of temperature control. Would you elaborate?

A. Many reported issues in viscosity measurement stem from the inability to control or determine the temperature of the material being measured. Numerous materials exhibit significant changes in viscosity with even slight temperature variations.

A viscosity measurement lacks meaning unless the temperature at the time of measurement is known and recorded.

Typically, higher-viscosity materials experience more substantial changes with temperature. For instance, standard oils used for cup calibration change between 3% and 8% per degree Celsius, based on their viscosity at the standard operating temperature.

- Q. What temperature should I aim for in my measurements?

A. Conducting viscosity measurements at 25 degrees Celsius (77 degrees Fahrenheit) is common practice. However, measurements can occur at other agreed-upon temperatures when practical limitations exist in certain processes. Regardless of the temperature used, it must be stated along with the viscosity determination.

- Q. Is it crucial for the cup to match the product's temperature before measurement?

A. Yes. Failure to do so can alter the product's temperature during the drain time. It is advisable to measure the temperature in the efflux stream and place the cup in the material before the determination to ensure both are at the desired temperature. Conducting measurements in a draft-free area that closely matches the measurement temperature facilitates temperature control.

- Q. Can measured drain time for a specific material be adjusted to a target temperature?

A. To a certain extent, yes. This adjustment is possible if the temperature index of the material is known. The temperature index represents the percentage change in viscosity per degree of temperature within a given temperature range.

The process for determining and using the temperature index for a specific material is detailed in the comprehensive product bulletins for viscosity cups manufactured by Gardco, the Paul N. Gardner Company.

Addendum

- Q. Can I exchange a viscosity cup for another size orifice after trying it?

A. Our policy states that once a cup is sold, we cannot accept its return for credit or exchange it for another size or type of cup.

Once a cup has been used with a material, it is impossible to clean and restore it to its original condition when purchased. Before ordering, ensure you know the appropriate orifice size and cup type that suits your requirements.

- Q. Why should I not report Zahn viscosity cup readings solely in seconds efflux time?

A. Reporting solely in seconds efflux time can be misleading due to the various makes of Zahn cups, each providing different readings for the same liquid at the same temperature. For instance, 40 seconds of efflux in one make cup could be 60.8 seconds in another make cup.

It is crucial to record seconds efflux time and determine the actual viscosity by converting seconds to centistokes using your Gardco Cup Conversion Table.

Including the cup maker's name and the temperature at the time of the test in your report, like "30.6 seconds, Gardco EZ Cup #2, 61.3 centistokes viscosity @ 77 °F (25 °C)," ensures reliable recorded information.

- Q. How can I convert centipoises to centistokes?

A. Centistokes are calculated by dividing centipoise by density (or weight per gallon times 0.120). To perform this conversion, you need to know the density or weight per gallon of the material.

For example, if the material's weight per gallon is 9.5, multiply 9.5 by 0.120 to determine its density. Assuming the material has a viscosity of 150 centipoises, you can then perform the conversion.

9.5 X 0.120 = 1.14

150 ÷ 1.14 = 132 centistokes.

centipoises ÷ (weight per gallon x 0.120) = centistokes

- Q. If I know the viscosity in centistokes (an example: 132) and the weight per gallon of the material (i.e. 9.5), how do I convert to centipoises viscosity?

A. Centistokes X (weight per gallon x 0.120) = centipoises

132 X 1.14 = 150 centipoises

- Q. I am using two new EZ#2 cups, and they are giving different readings—17 seconds and 20 seconds efflux time. Why are these readings so different?

A. These cups are being used below the recommended 20 to 60-second range specified in the instrument's product leaflet. There are solid technical reasons for this suggested range.

As viscosity approaches zero, the efflux time from the #2 cup is around 16.3 seconds, and the material's viscosity has minimal influence on drain time near this minimum. Here's a relationship between centistokes and drain time seconds for EZ#2:

Centistokes Seconds Drain Time - EZ#2

0.00 16.3

3.66 17.0

18.65 20.0

You should use the #1 EZ cup instead of the #2 EZ cup. Additionally, for work below 10 centistokes, the only recommended cup-type instrument is the Ford cup with the #0 orifice.

- Q. My supplier advises buying a No. 2 Zahn Type Cup, and my lacquer should run through this cup orifice within 20-24 seconds. Do you produce such a cup?

A. Your supplier's information lacks specifics. It is essential to know the maker's name, indicated on the nameplate. Various Zahn Cups available provide diverse readings, potentially leading to meaningless and misleading results.

If it is a No. 2 EZ Cup with a Gardco or Paul N. Gardner Company nameplate, consult our No. 2 EZ Cup Conversion Grid accompanying each Gardco cup. This grid displays seconds (20, 21, 22, 23, and 24) and the corresponding viscosities in centistokes (18.7, 23.2, 27.6, 31.9, and 36.1 centistokes).

With a Gardco-made No. 2 EZ viscosity cup, you know the efflux time and the actual viscosity in centistokes. This information provides a solid basis for expressing your results, a feature not available with other makes of cups.

The compiled questions and answers address crucial aspects of viscosity measurement using widely used viscosity cups. They encompass commonly asked queries from our customers. While these cover the essentials, additional questions may arise or require further clarification.

The Paul N. Gardner Company is committed to aiding you in viscosity measurement challenges by offering superior products and invaluable information gathered through the design and manufacturing process.

This information has been sourced, reviewed and adapted from materials provided by Paul N. Gardner Company, Inc.

For more information on this source, please visit Paul N. Gardner Company, Inc.