This article explains the necessary materials for calibrating a laboratory stand viscosity cup.

This information applies solely to viscosity cups produced by The Paul N. Gardner Company, Inc. (Gardco).

- One Gardco Laboratory Stand Viscosity Cup.

- The Conversion Grid sheet (specific to the chosen cup) converts seconds efflux time to centistoke viscosity. Each Gardco Cup comes with this datasheet.

- One pint of certified calibration oil suitable for the chosen cup (refer to the provided chart).

Source: Paul N. Gardner Company, Inc.

| Standard Oil |

Centistoke*

Viscosity |

Std. Ford

Cup No. |

Gardco ISO

Cup No. |

Gardco Din

Cup No. |

Fisher Std.

Cup No. |

Parlin

Cup No. |

| G-6 |

8.9 |

0 |

- |

- |

- |

- |

| G-10 |

19 |

1 |

3 |

- |

- |

- |

| G-20 |

34 |

- |

- |

- |

1 |

- |

| G-35 |

64 |

2 |

4 |

- |

2 |

- |

| † G-35-P |

64 |

- |

- |

- |

- |

1 |

| G-60 |

120 |

3, 4 |

- |

- |

3 |

- |

| G-100 |

230 |

- |

6 |

4 |

- |

- |

| † G-100-P |

270 |

- |

- |

- |

- |

2 |

| G-200 |

450 |

5 |

- |

- |

4 |

- |

| G-350 |

880 |

- |

8 |

- |

- |

- |

| † G-350 |

1,020 |

- |

- |

- |

- |

3 |

| † G-J3000-P |

10,800 |

- |

- |

- |

- |

4 |

* These are nominal values. For the actual kinematic viscosity of the standard, refer to the value on the label.

† Special temperature @ 23 °C. |

- For utmost calibration accuracy, it is recommended to use ASTM mercury-filled glass thermometers with a precision of 0.1 °C (0.2 °F). Options include:

- Gardco Cat. No. TH-02232 °F ASTM mercury-filled glass thermometer, 10.8" length, 19-27 °C. range.

- Gardco Cat. No. TH-02233 °F ASTM mercury-filled glass thermometer, 10.8-inch length, 66-80 °F. range.

- A container with a 250 ml capacity.

- Gardco Cat. No. TM-AX705 digital electronic stopwatch, accurate to 0.01 seconds.

- Reference materials:

- Gardco Viscosity cup leaflet (specific to the chosen cup)

- Viscosity Cups-Common Questions and Their Answers leaflet

- Gardco Viscosity Cup Equivalent Wall Chart (VI-VCC)

This information specifically addresses viscosity cups (excluding Parlin cups*) crafted by The Paul N. Gardner Company, Inc. (Gardco).

* Please consult the Parlin Viscosity Cup Literature for calibration procedures specific to this cup. Meets ASTM D1084, Test Method A

- Inspect the cup for any visible blockage, damage to the orifice area, and overall cleanliness.

- Position the cup in the stand and ensure the top edge is leveled, with the cup's bottom around 6 inches above the container's bottom.

- Select the recommended Certified Viscosity Standard for the cup to calibrate, verifying the standard's expiration date.

- Pour adequate oil into a 250 ml container, exceeding the cup's capacity.

- Ensure the oil reaches a target temperature of 25 °C ± .5 °C. Use a calibrated ASTM mercury-filled thermometer to monitor and slightly adjust the temperature by wrapping a hand around the container and stirring the oil slowly.

- Fill the cup to the top edge (slightly overfill and remove excess with a straight edge or glass plate), while covering the orifice with a finger. Pour slowly to minimize air bubbles.

- Release the finger from the orifice and start timing with a stopwatch at 1/10th second or better.

- Keep the thermometer in the efflux stream to maintain a consistent temperature throughout the run.

- Stop the timer when the first distinct break in the efflux stream occurs near the bottom of the cup, ensuring minimal air bubbles that might cause premature breaks.

- Record time and temperature, repeating the process while maintaining temperature drift between runs at ±.2 °C. Disregard runs more than 0.5 seconds apart.

- Adjust times for temperature deviation and average three valid runs.

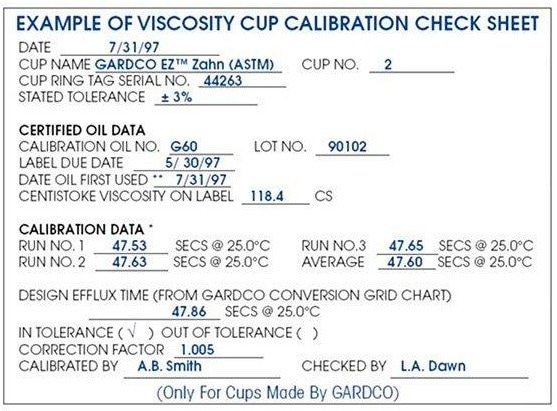

- Divide the design time on the Viscosity Standard by the average to determine the correction factor.

- Assess if the cup meets or exceeds the manufacturer's specifications.

This procedure aligns with ASTM D1200 & D5125 requirements.

For Gardco Dip-Type Cups

This information specifically applies to viscosity cups manufactured by The Paul N. Gardner Company, Inc. (Gardco).

Here is a breakdown of the necessary materials for calibrating a dip-type viscosity cup:

- One GARDCO Dip-Type Viscosity Cup.

- The Conversion Grid sheet (specific to the chosen cup) used for converting seconds efflux time to centistoke viscosity. Each Gardco Cup includes this data sheet.

- One pint of certified calibration oil suitable for the chosen cup (refer to the provided chart).

Source: Paul N. Gardner Company, Inc.

| Standard Oil |

Centistoke* Viscosity |

EZ Cup No. |

S90 Zahn Cup No. |

Mini Ford Dip Cup No. |

Gardco/ Fisher Dip Cup No. |

Std. Ford Dip Cup No. |

Gardco/ISO Dip Cup mm |

Gardco/Din Dip Cup mm |

| G-6 |

8.9 |

- |

- |

0 |

- |

- |

- |

- |

| G-10 |

19 |

1 |

- |

1 |

- |

- |

3 |

- |

| G-20 |

34 |

- |

1 |

- |

1 |

- |

- |

- |

| G-35 |

64 |

- |

- |

2 |

2 |

- |

4 |

- |

| G-60 |

120 |

2 |

2 |

3, 4 |

3 |

3, 4 |

- |

- |

| G-100 |

230 |

- |

3 |

- |

- |

- |

6 |

4 |

| G-200 |

450 |

3, 4 |

- |

5 |

4 |

5 |

- |

- |

| G-350 |

880 |

5 |

4, 5 |

- |

- |

- |

**8 |

- |

* These are nominal values. For the actual kinematic viscosity of the standard, refer to the value on the label.

** Note: The 8mm ISO Cup is not available in the Dip version. |

- For the highest calibration accuracy, it is recommended to utilize ASTM mercury-filled glass thermometers with an accuracy of 0.1 °C (0.2 °F). Options include:

- Gardco Cat. No. TH-02232 °F ASTM mercury-filled glass thermometer, 10.8-inch length, 19-27 °C. range.

- Gardco Cat. No. TH-02233 °F ASTM mercury-filled glass thermometer, 10.8-inch length, 66-80 °F. range.

- Container, 600 ml capacity SS beaker SS-80600. A 1000 ml beaker (not supplied) is recommended for the Fisher Dip Cup.

- Gardco Cat. No. TM-AX705 digital electronic stopwatch, accurate to 0.01 seconds.

- Reference materials:

- Gardco Viscosity cup leaflet (specific to the chosen cup)

- Viscosity Cups-Common Questions and Their Answers leaflet

- Gardco Viscosity Cup Equivalent Wall Chart (VI-VCC)

This information specifically pertains to viscosity cups produced by The Paul N. Gardner Company, Inc. (Gardco).

- Inspect the cup for any evident obstruction, damage to the orifice area, and overall cleanliness.

- Choose the recommended Certified Viscosity Standard for the cup to calibrate, ensuring the standard's expiration date has not passed.

- Pour enough oil into a 500 ml container to fully submerge the cup.

- Use a calibrated ASTM mercury-filled thermometer to adjust the oil temperature to the 25 °C ± .5 °C target. Proper temperature is crucial, and slight adjustments can be made by wrapping a hand around the beaker and gently stirring the oil.

- Place the cup in the oil and allow 1 to 5 minutes for the cup and oil to reach thermal equilibrium.

- Lift the cup vertically to a maximum distance of 6 inches from the oil surface. Start timing with a stopwatch accurate to one-tenth of a second or better as the top edge of the cup breaks the oil surface.

- Keep the thermometer in the beaker to ensure consistent temperature throughout the process.

- Stop the timer when the first distinct break in the efflux stream occurs near the cup's bottom, minimizing air bubbles that might cause premature breaks.

- Record time and temperature, repeating the process while maintaining temperature drift between runs at ±.2 °C. Disregard runs more than 0.5 seconds apart.

- Adjust times for temperature deviation and average three valid runs.

- Divide the design time listed on the Viscosity Standard by the average to determine the correction factor.

- Determine if the cup meets or exceeds the manufacturer's specifications.

** This procedure complies with the requirements of ASTM D4212 **

Image Credit: Paul N. Gardner Company, Inc.

* When conducting numerous determinations on similar products within the same viscosity range, creating a graph to convert measured temperature and viscosity cup efflux time in seconds to seconds at a fixed temperature (usually 25 °C or 77 °F) can be beneficial.

See the "Temperature" section in the Viscosity Cup leaflet in this manual for suggested steps in preparing such a graph.

** Upon completion of standard oil usage, inspect it for any form of contamination. If dirt specks are noticed, a fine wire mesh filter can be employed. In the case of accidental water contamination settled at the bottom of the container, discard the contaminated water portion by pouring off the clean oil.

Return the oil to the bottle and mark the date of initial use on the label. When stored at standard ambient temperature, the oil remains viable for one year from the date of first use, provided it remains uncontaminated.

Cleaning

Guide for Removing the G-Series Calibrating Oil from Gardco Viscosity Cups

Any residual material in the cup should be flushed out using an appropriate solvent. Light naphtha, heptane, octane, highly aromatic solvents, or any other petroleum-derived hydrocarbon solvent can serve this purpose. Varsol® is a commercial solvent highly effective for this task.

Thoroughly dry the viscosity cup using a lint-free cloth. For a second cleaning, use a highly volatile solvent to ensure the rapid evaporation of any remaining hydrocarbon solvents from the initial process once the sample is flushed out of the cup.

Hypersolve, MEK, and Alcohol are suitable for aluminum cups, while Hypersolve and Alcohol work well for stainless steel cups. Acetone, due to its high volatility and ability to dissolve traces of petroleum solvents and water, is commonly used as the second solvent.

In the third step, a low-velocity stream of clean air will suffice to evaporate any remaining traces of volatile solvent.

Rapid evaporation of these solvents should be avoided, as it may cause surface cooling to an extent that humid air could reach below the dew point, resulting in water film formation on the cup. Varsol is a registered trademark of Exxon Company.

Caution

A note of caution: Standard oils exhibit viscosity changes within the range of 3% to 8% per degree Celsius within the 25 °C normal measuring range. To attain accurate results, ensure the temperature of the measured products is adjusted to within 0.1 °C of the specified temperature.

The information contained herein, or supplied by us or on our behalf in any other manner is based on data obtained by our research and is considered accurate. However, NO WARRANTY IS EXPRESSED OR IMPLIED REGARDING THE ACCURACY OF THESE DATA, THE RESULTS TO BE OBTAINED FROM THE USE THEREOF, OR THAT ANY SUCH USE WILL NOT INFRINGE ANY PATENT. This information is furnished upon the condition that the person receiving it shall make his tests to determine the suitability thereof for his particular purpose.

This information has been sourced, reviewed and adapted from materials provided by Paul N. Gardner Company, Inc.

For more information on this source, please visit Paul N. Gardner Company, Inc.